Additive of electrolyte for aluminum electrolysis process and method for preparing same

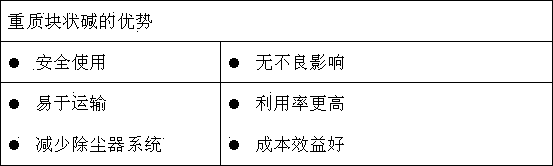

An additive and aluminum electrolysis technology, applied in the chemical industry, can solve problems such as aluminum electrolytes are prone to impurities, and achieve the effects of safe use, accelerated boiling and circulation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

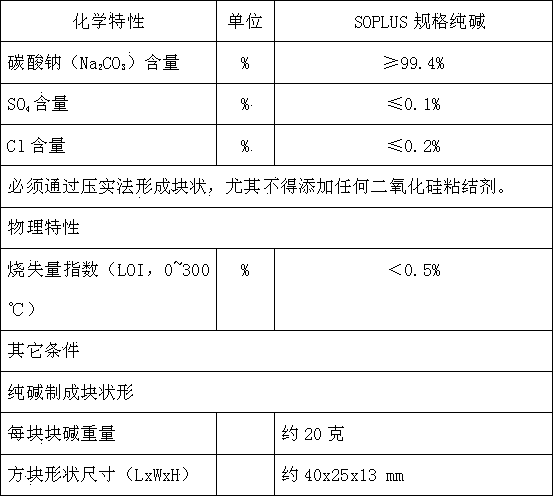

[0018] Including additives used in the electrolyte during the aluminum electrolysis process, the main components of the aluminum electrolyte are composed of alumina and cryolite, cryolite is the solvent, alumina is the solute, aluminum fluoride, heavy alkali block, lithium fluoride, fluoride Magnesium and calcium fluoride are additives, among which aluminum fluoride is added by 0.012%, heavy alkali block is added by 0.015%, lithium fluoride is added by 0.001%, magnesium fluoride is added by 0.001%, and calcium fluoride is added by 0.001%;

[0019] In the process of aluminum electrolysis, the ratio of cryolite is constantly changing. At the initial stage of electrolytic cell start-up, due to the selective absorption of NaF by the cathode carbon lining, the loss rate of NaF is greater than the loss rate of AIF, volatilization and decomposition by Na2O, CaO, H2O, The cryolite ratio will automatically decrease, therefore, it is necessary to adjust by adding alkali blocks to keep th...

Embodiment 2

[0021] Including additives used in the electrolyte during the aluminum electrolysis process, the main components of the aluminum electrolyte are composed of alumina and cryolite, cryolite is the solvent, alumina is the solute, aluminum fluoride, heavy alkali block, lithium fluoride, fluoride Magnesium and calcium fluoride are additives, among which aluminum fluoride is added by 0.013%, heavy alkali block is added by 0.016%, lithium fluoride is added by 0.002%, magnesium fluoride is added by 0.002%, and calcium fluoride is added by 0.002%;

[0022] In the process of aluminum electrolysis, the ratio of cryolite is constantly changing. At the initial stage of electrolytic cell start-up, due to the selective absorption of NaF by the cathode carbon lining, the loss rate of NaF is greater than the loss rate of AIF, volatilization and decomposition by Na2O, CaO, H2O, The cryolite ratio will automatically decrease, therefore, it is necessary to adjust by adding alkali blocks to keep th...

Embodiment 3

[0024] Including additives used in the electrolyte during the aluminum electrolysis process, the main components of the aluminum electrolyte are composed of alumina and cryolite, cryolite is the solvent, alumina is the solute, aluminum fluoride, heavy alkali block, lithium fluoride, fluoride Magnesium and calcium fluoride are additives, among which aluminum fluoride is added by 0.014%, heavy alkali block is added by 0.017%, lithium fluoride is added by 0.003%, magnesium fluoride is added by 0.003%, and calcium fluoride is added by 0.003%;

[0025] The molecular ratio is the ratio of the number of molecules of sodium fluoride to aluminum fluoride in the electrolyte. Most of the electrolytic production now adopts a molecular ratio of 2.2-2.4. The electrolyte is acidic, and a low molecular ratio is conducive to reducing the electrolysis temperature and improving the current efficiency. The lower the ratio, the lower the solubility of alumina, and a large amount of precipitation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com