Full-polyester moisture-absorbing quick-drying high-performance sports fabric and preparation method thereof

A hygroscopic, quick-drying, fabric technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of difficult to achieve the effect, rough and non-smooth feel, and achieve market competitiveness, good application prospects, improvement The effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

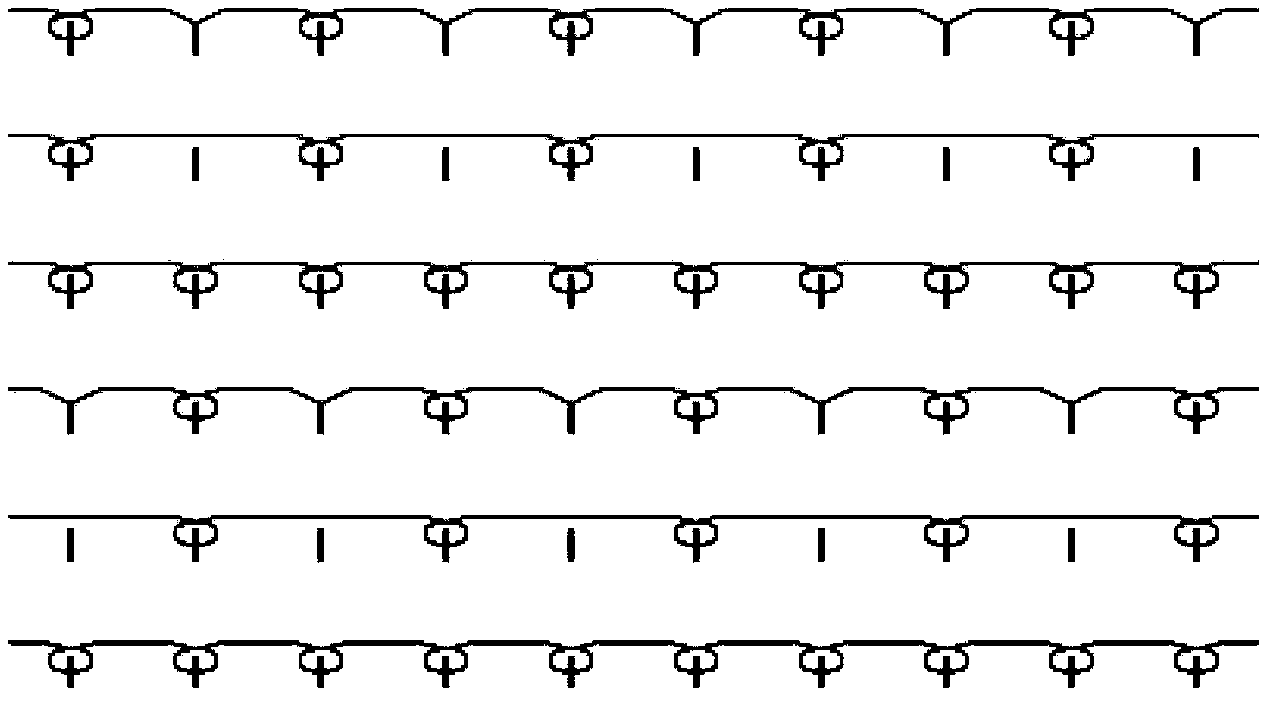

[0027] Such as figure 1 As shown, this embodiment provides a kind of all-polyester moisture-absorbing and quick-drying high-performance sports fabric. The weaving process is as follows: 1F uses odd-numbered needles to form loops and even-numbered needles to tuck; 2F uses odd-numbered needles to tuck and even-numbered needles to float; 3F All knitting needles are used for full looping, 4F is used for odd-numbered needles for tucking and even-numbered needles for looping, 5F is used for odd-numbered needles for floating and even-numbered needles for tucking, and 6F is used for all knitting needles to form full loops. Use 1F-6F as the cycle to form the fabric.

[0028] Note: 1F means the first triangular structure on the weft knitting machine, the same as 2F-6F.

[0029] (1) Select 40-inch polyester staple fiber as raw material, and weave it on a large circular machine to obtain a blank;

[0030] (2) Pre-shape the above blank at 150°C for 60 seconds;

[0031] (3) Add refining...

Embodiment 2

[0037] Such as figure 1 As shown, this embodiment provides a kind of all-polyester moisture-absorbing and quick-drying high-performance sports fabric. The weaving process is as follows: 1F uses odd-numbered needles to form loops and even-numbered needles to tuck; 2F uses odd-numbered needles to tuck and even-numbered needles to float; 3F All knitting needles are used for full looping, 4F is used for odd-numbered needles for tucking and even-numbered needles for looping, 5F is used for odd-numbered needles for floating and even-numbered needles for tucking, and 6F is used for all knitting needles to form full loops. Use 1F-6F as the cycle to form the fabric.

[0038] Note: 1F means the first triangular structure on the weft knitting machine, the same as 2F-6F.

[0039] (1) Select 32-inch polyester staple fiber as raw material, and weave it on a large circular machine to obtain a blank;

[0040] (2) Pre-shape the above blank at 160°C for 60 seconds;

[0041] (3) Add refining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com