Distributed optical fiber grating anchor rod group stress monitoring system for coal mine roadway

A technology of distributed optical fiber and bolt group stress, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of inconvenient operation, uneconomical, time-consuming, etc., to reduce workload and reduce monitoring costs , The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

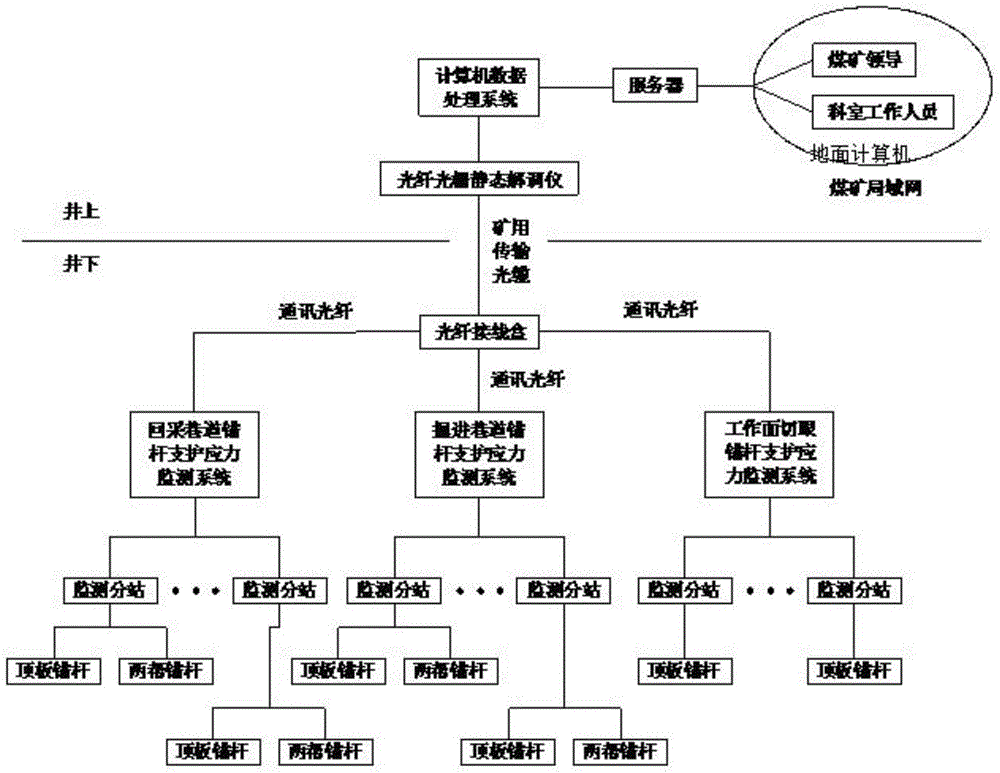

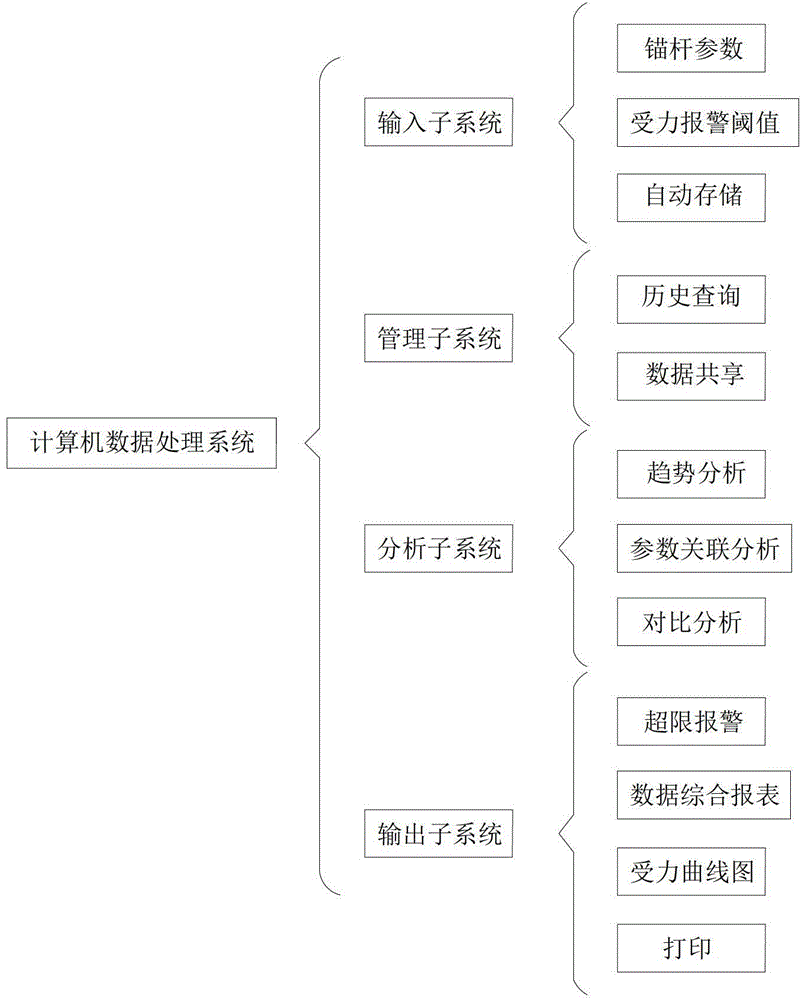

[0024] Example 1: In figure 1 Among them, a coal mine roadway distributed fiber grating bolt group stress monitoring system, including mining roadway bolting stress monitoring subsystem, driving roadway bolting stress monitoring subsystem and working face cut hole bolting stress monitoring subsystem; the above three bolting stress monitoring subsystems all include several monitoring sub-stations, and each monitoring sub-station monitors the force of the roof bolt and the two side bolts, and each bolting stress monitoring subsystem The roof bolts and the two groups of bolts in the monitoring substation are connected in series through communication optical fibers, and the communication optical fibers at the outlets of the three bolt support stress monitoring subsystems are connected to the mine-used transmission cables through optical fiber junction boxes, and the mine-use transmission cables Connect to the input port of the fiber grating static demodulator, the fiber grating st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com