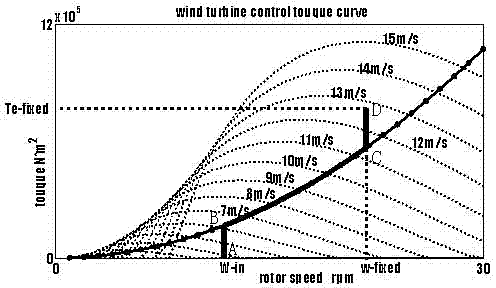

Variable-speed variable-pitch wind generating set maximum power tracking control method based on internal model control

A wind turbine, maximum power tracking technology, applied in the control of wind turbines, wind turbines, wind power generation and other directions, can solve problems such as deviation, aerodynamic torque fluctuations, and inability to efficiently achieve optimal maximum power tracking control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Calculate the total moment of inertia of the low-speed shaft of the transmission system according to the distribution of the mass distance between the blades and the hub of the variable-speed and variable-pitch wind turbine from the center of rotation ; Calculate the total moment of inertia of the high-speed shaft of the transmission system according to the distribution data of the rotor mass distance from the rotation center of the variable-speed variable-pitch wind turbine generator , generally speaking, the relative moment of inertia of the transmission shaft or gearbox is very small and can be approximately ignored.

[0078] Obtain the blade airfoil data of variable speed and variable pitch wind turbines, and calculate the optimal resistance torque parameters of the wind rotor below the rated wind speed according to the momentum-blade element theorem, finite element calculation method or relevant commercial calculation software .

[0079] The relevant data of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com