High-temperature measuring section for fuel gas turbine combustor test

A technology for gas turbines and combustion chambers, which is applied in the field of high-temperature measurement sections for combustion chamber tests, can solve the problems of high cost and easy damage, and achieve the effects of low cost, low degree of damage, and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

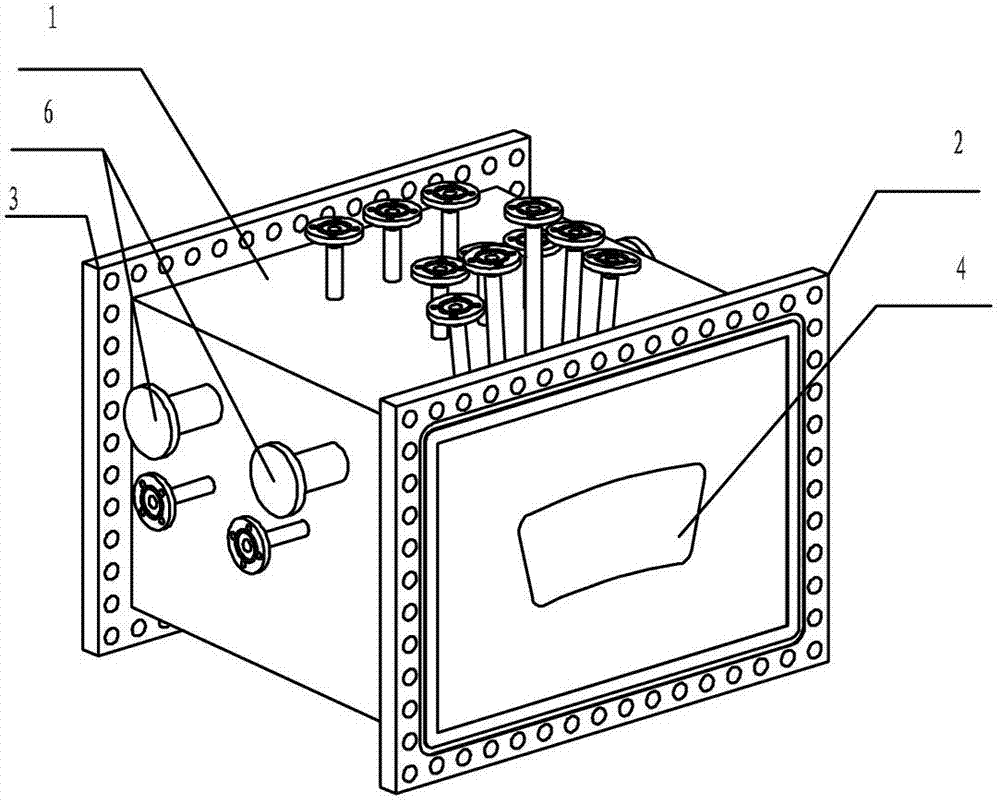

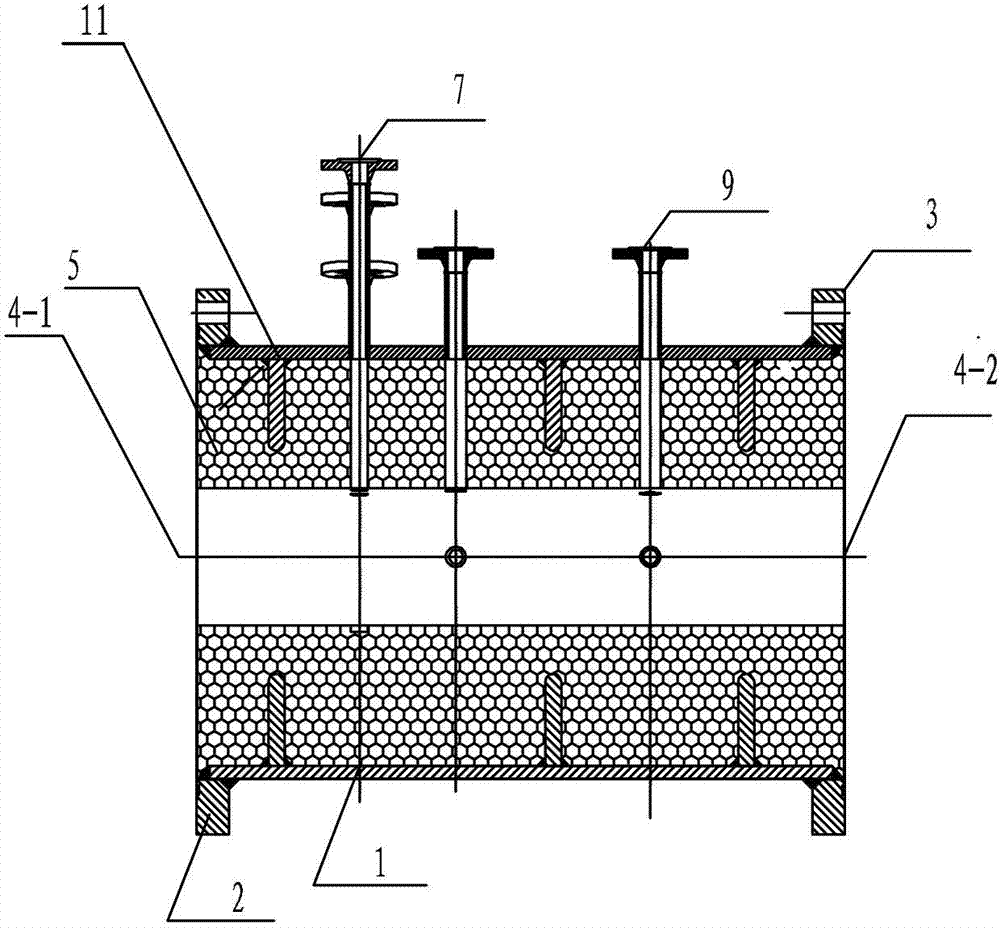

[0015] Specific implementation mode one: combine Figure 1 ~ Figure 4 In this embodiment, the high-temperature measurement section for gas turbine combustor test includes an outer cover shell 1, a front flange 2, a rear flange 3 and a high-temperature gas passage 4, and the front end of the outer cover shell 1 is provided with a front flange 2, so The rear end of the housing shell 1 is provided with a rear flange 3, and a high-temperature gas channel 4 is opened between the front flange 2 and the rear flange 3. It is characterized in that the high-temperature measurement section for the gas turbine combustion chamber test also includes a central heat-resistant The pouring material 5 , the central heat-resistant pouring material 5 is fixed and filled on the inner surface of the housing shell 1 by inverted T-shaped nails 11 .

[0016] When the high-temperature measurement section for gas turbine combustor test of the present invention is in use, the exhaust gas (flue gas) of the...

specific Embodiment approach 2

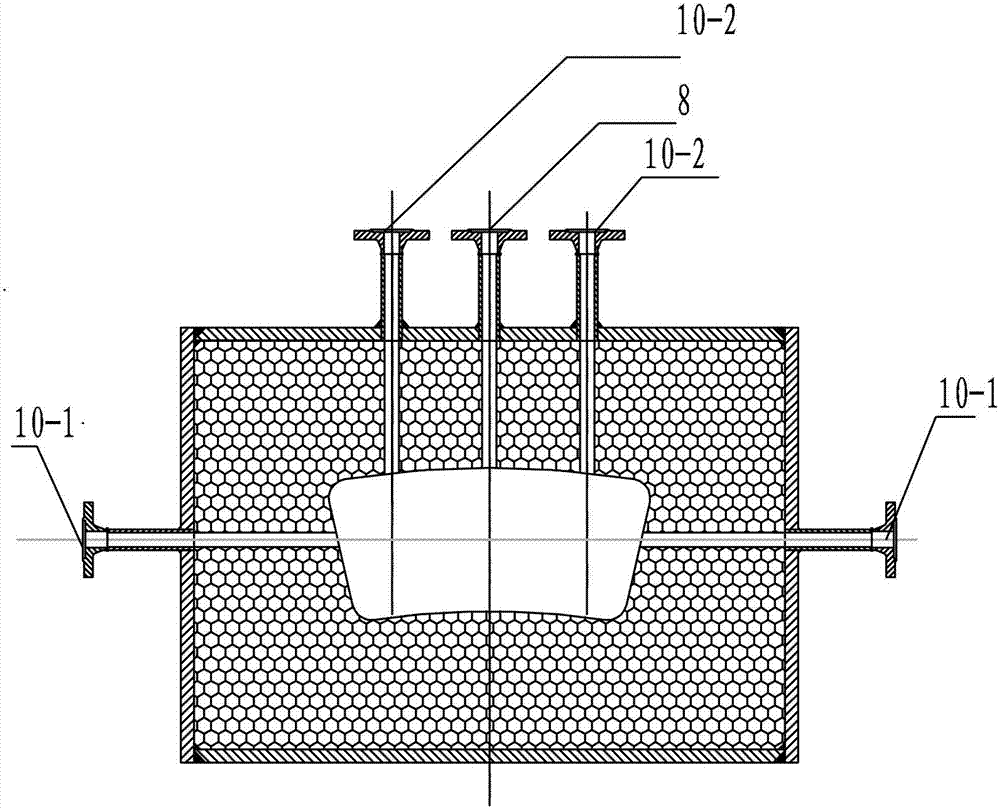

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the high-temperature measurement section for the gas turbine combustor test also includes a lifting lug 6, a temperature measurement probe interface 7, a flue gas measuring instrument interface 8, and a cooling water interface 9 , the lifting lugs 6 are arranged on both sides of the outer cover shell 1, the static pressure sensor interface 10-1 is arranged directly below the lifting lugs 6, and the temperature measurement probe interface 7 is set on the upper end of the outer cover shell 1 close to the high-temperature gas At the channel entrance 4-1, the cooling water interface 9 is set at the upper end of the outer cover shell 1 close to the high-temperature gas channel outlet 4-2, and there are two ports between the temperature measurement probe interface 7 and the cooling water interface 9 A total pressure sensor interface 10-2, and the flue gas measuring instrument interface 8 is arranged ...

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the outer casing 1 , the front flange 3 and the rear flange 4 are made of ordinary low alloy steel. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com