Extreme value optimization self-adjusting digital PID control method used for megawatt inverter system

An inverter system and extreme value optimization technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of complex design and implementation, low optimization efficiency, and difficulty in real-time online adjustment of PID control parameters. , to achieve the best performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below with reference to the accompanying drawings of the present invention. The present invention can also be implemented in many different forms, so it should not be considered as limited to the embodiments listed in the specification. On the contrary, this embodiment is provided to illustrate the implementation and completeness of the present invention and to describe it to those skilled in the relevant art. The specific implementation process of the present invention.

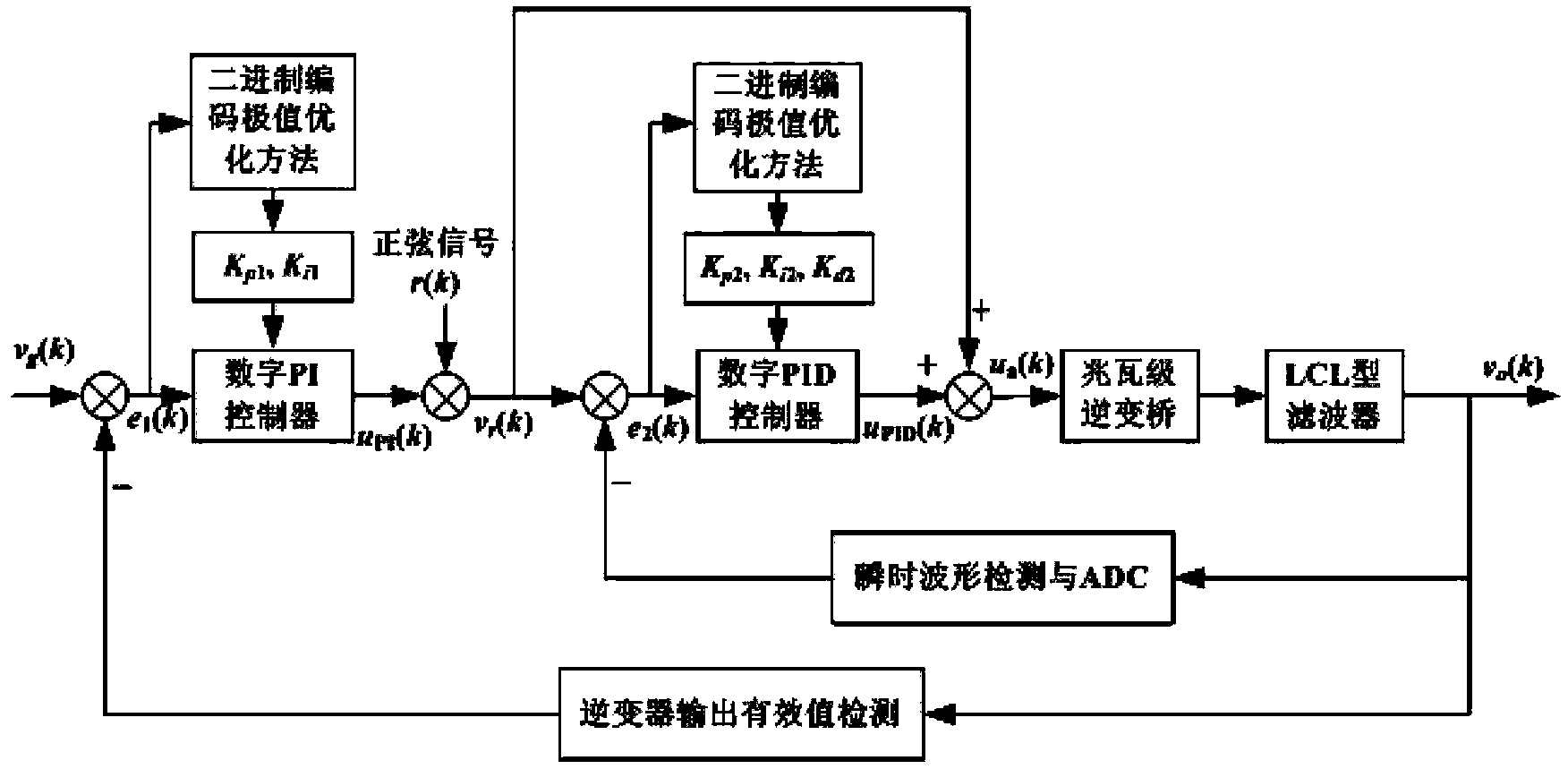

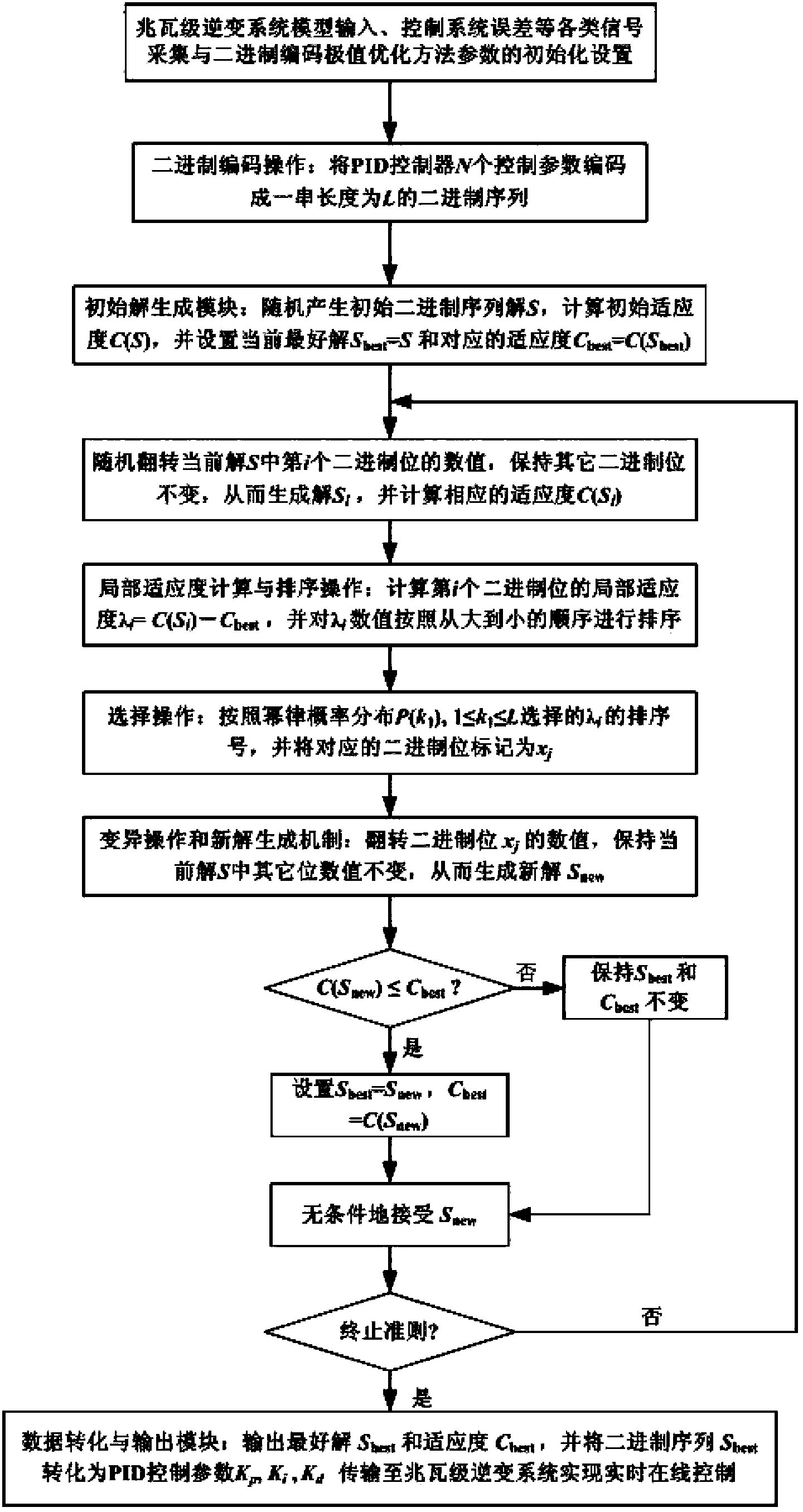

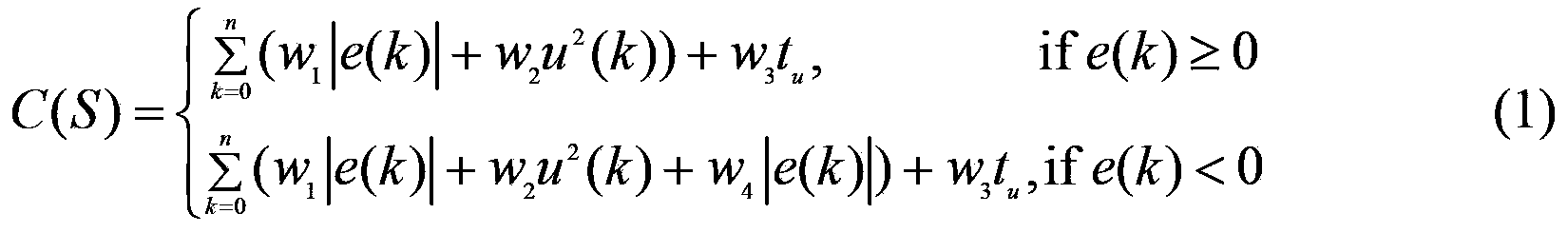

[0027] The block diagram of the optimized self-tuning digital PID control system of megawatt inverter extreme value is attached figure 1 Shown. The specific implementation flow chart of the extreme value optimization self-tuning digital PID control method used in the megawatt inverter system is as attached figure 2 Shown. The method is to use the model input of the megawatt inverter system, the system error signal and the initial value of the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com