Schottky semiconductor device with insulating layer isolated super-junction structure and preparation method for Schottky semiconductor device

A technology of semiconductor and insulating layer, applied in the field of preparation of Schottky semiconductor device with insulating layer isolation superjunction structure, can solve the problem of high voltage environment, high on-resistance and reverse leakage current that cannot be applied, and fast turn-on and turn-off speed. and other problems, to achieve the effect of improving forward conduction characteristics, increasing reverse breakdown voltage, and reducing forward conduction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

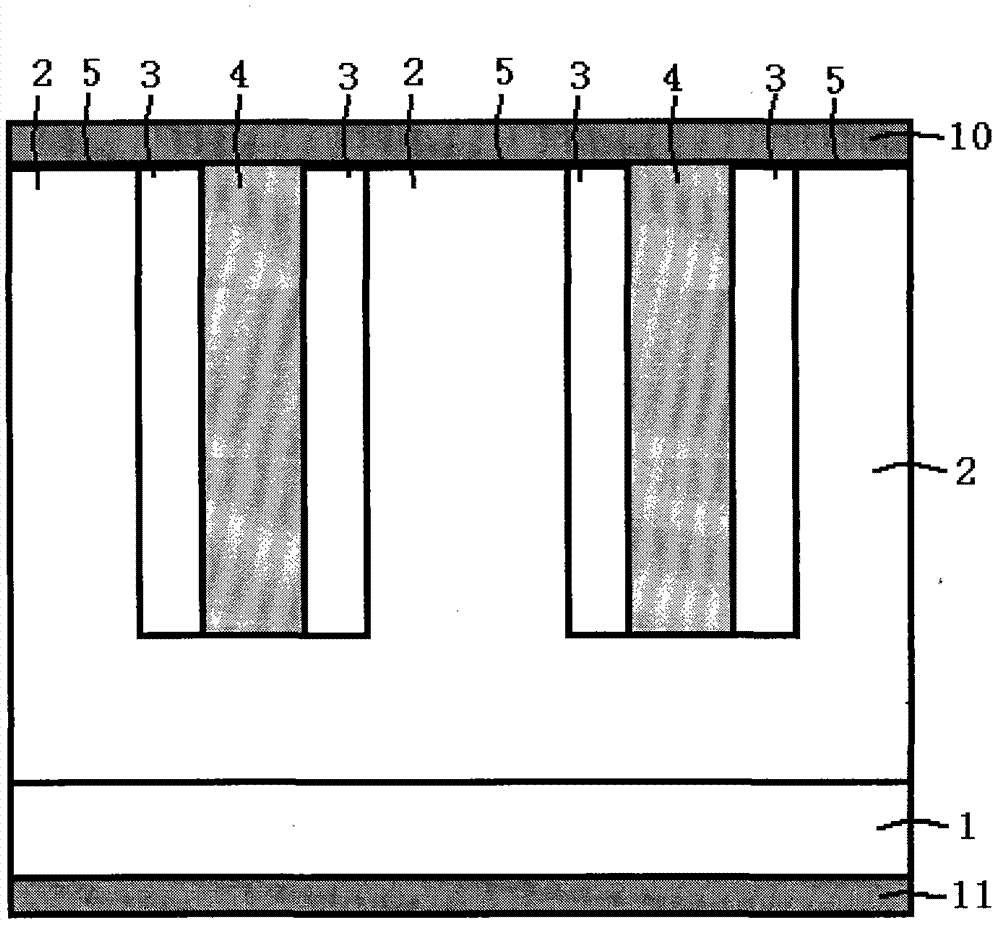

[0020] figure 1 It is a Schottky semiconductor device with insulating layer isolation super junction structure of the present invention, combined below figure 1 The semiconductor device of the present invention will be described in detail.

[0021] A Schottky semiconductor device with an insulating layer isolation superjunction structure, comprising: a substrate layer 1, which is an N conductivity type semiconductor silicon material, and the doping concentration of phosphorus atoms is 1E19 / CM 3 , on the lower surface of the substrate layer 1, the electrode is drawn out through the lower surface metal layer 11; the N-type semiconductor silicon material 2, located on the substrate layer 1, is an N-conduction type semiconductor silicon material, and the doping concentration of phosphorus atoms is 1E16 / CM 3 ; P-type semiconductor silicon material 3, located between N-type semiconductor silicon material 2 and silicon dioxide 4, is a P-type semiconductor silicon material, and the d...

Embodiment 2

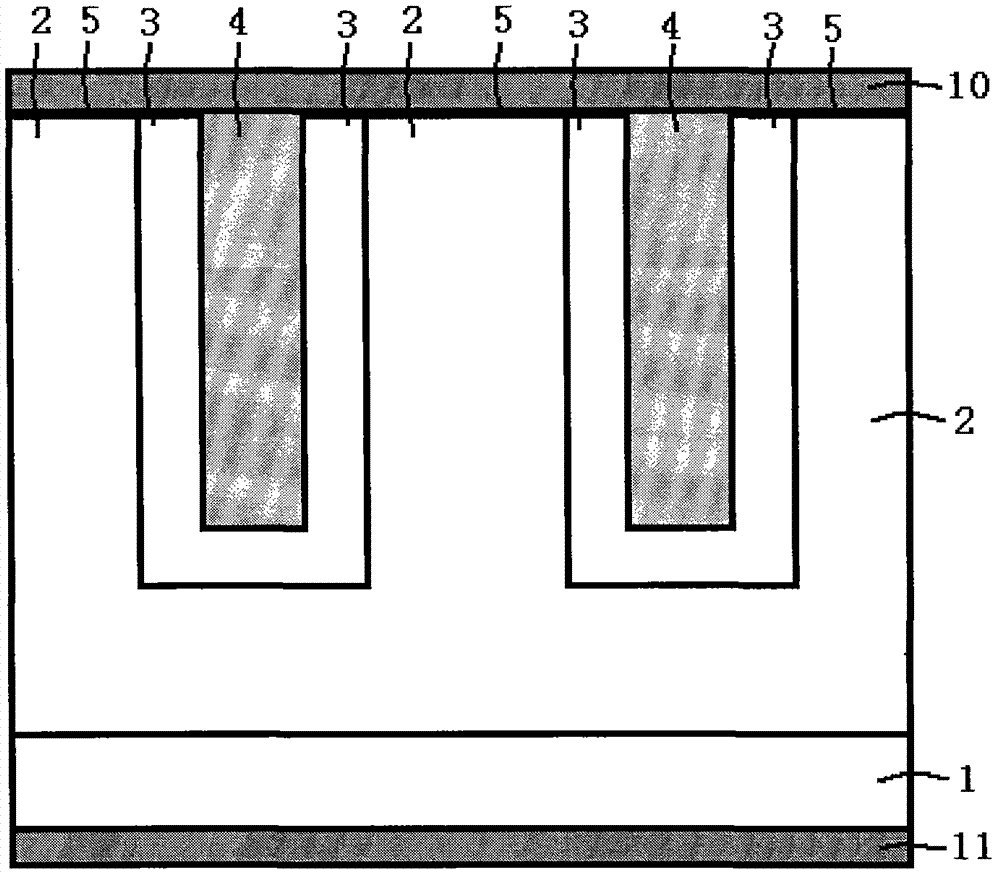

[0031] figure 2 It is a Schottky semiconductor device with insulating layer isolation super junction structure of the present invention, combined below figure 2 The semiconductor device of the present invention will be described in detail.

[0032] A Schottky semiconductor device with an insulating layer isolation superjunction structure, comprising: a substrate layer 1, which is an N conductivity type semiconductor silicon material, and the doping concentration of phosphorus atoms is 1E19 / CM 3 , on the lower surface of the substrate layer 1, the electrode is drawn out through the lower surface metal layer 11; the N-type semiconductor silicon material 2, located on the substrate layer 1, is an N-conduction type semiconductor silicon material, and the doping concentration of phosphorus atoms is 1E16 / CM 3 ; P-type semiconductor silicon material 3, located between N-type semiconductor silicon material 2 and silicon dioxide 4, is a semiconductor silicon material of P conductivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com