Assembled battery connection structure

A connection structure and battery combination technology, applied in the electrical field, can solve the problems of low production efficiency, large connection process consumption, environmental pollution, etc., and achieve the effects of improving production efficiency, saving precious metals, and eliminating environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

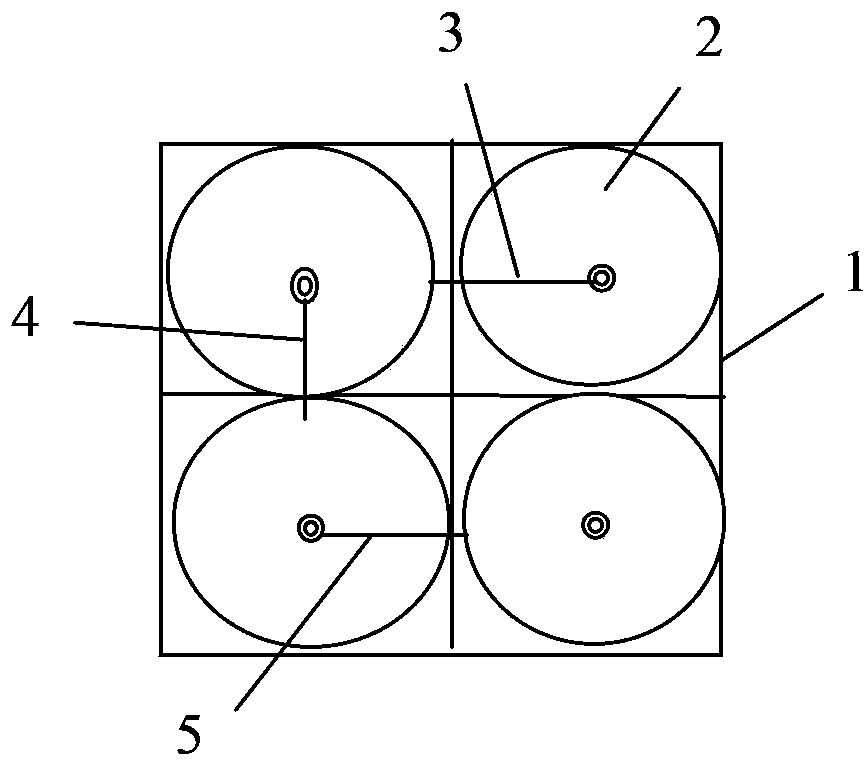

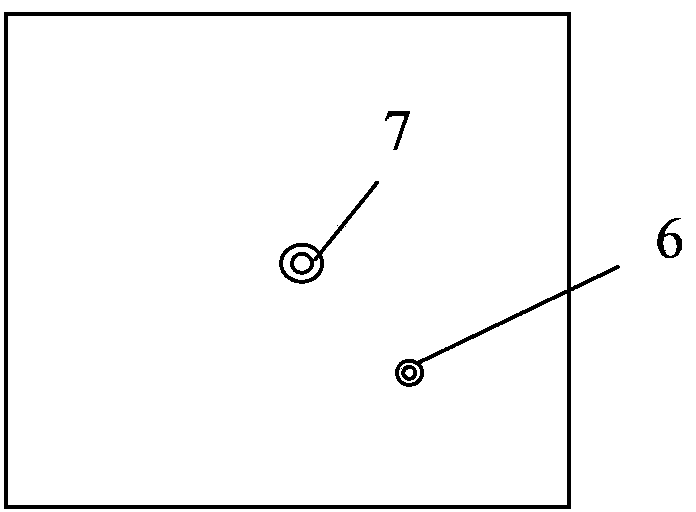

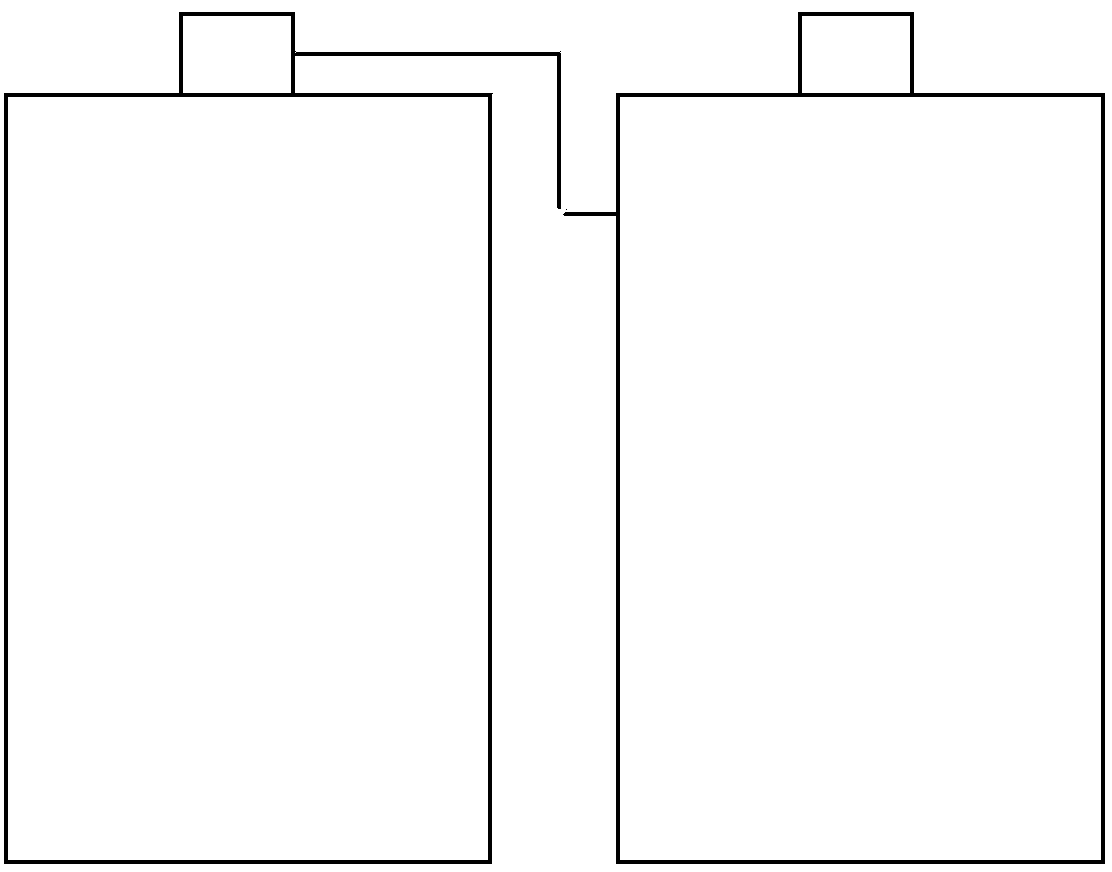

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a connection structure of an assembled battery of the present invention includes a battery case 1 and four single cells 2, wherein the four single cells 2 are arranged in two rows and two columns on the In the battery pack case 1 described above, the four single cells 2 are connected in series to form a battery pack through conductors, the conductors are made of springs, and the springs are arranged between the single cells 2 and the battery pack case 1, and related Between two adjacent single cells 2.

[0018] Further, the springs include torsion springs, cylindrical springs and pagoda springs.

[0019] Further, the positive and negative poles of the battery pack are respectively connected to a terminal.

[0020] Further, among the four single cells 2, a first torsion spring 3 is provided on the positive pole of the first single cell 2, and one end of the first torsion sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com