Solid state laser device array packaging structure and solid state laser device array packaging method

A technology of solid-state lasers and packaging structures, which is applied to laser devices, semiconductor laser devices, lasers, etc., can solve problems such as increasing operational difficulty, high bar laser requirements, and inability to meet array packaging of different power lasers, so as to avoid positive The effect of negative short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 is a solid-state laser array that encapsulates three semiconductor laser bars of different powers, wherein the power and length of the three semiconductor laser bars are shown in Table 1:

[0037] Table 1

[0038] semiconductor laser bar

Embodiment 2

[0039] Embodiment 2 is the packaging method of the packaging structure described in Embodiment 1.

Embodiment 3

[0040] Embodiment 3 is a solid-state laser array that encapsulates three semiconductor laser bars of different powers, wherein the power and length of the three semiconductor laser bars are shown in Table 2:

[0041] Table 2

[0042] semiconductor laser bar

the power

length

first bar

24W

4mm

second bar

54W

9mm

third bar

72W

12mm

[0043] Embodiment 1,

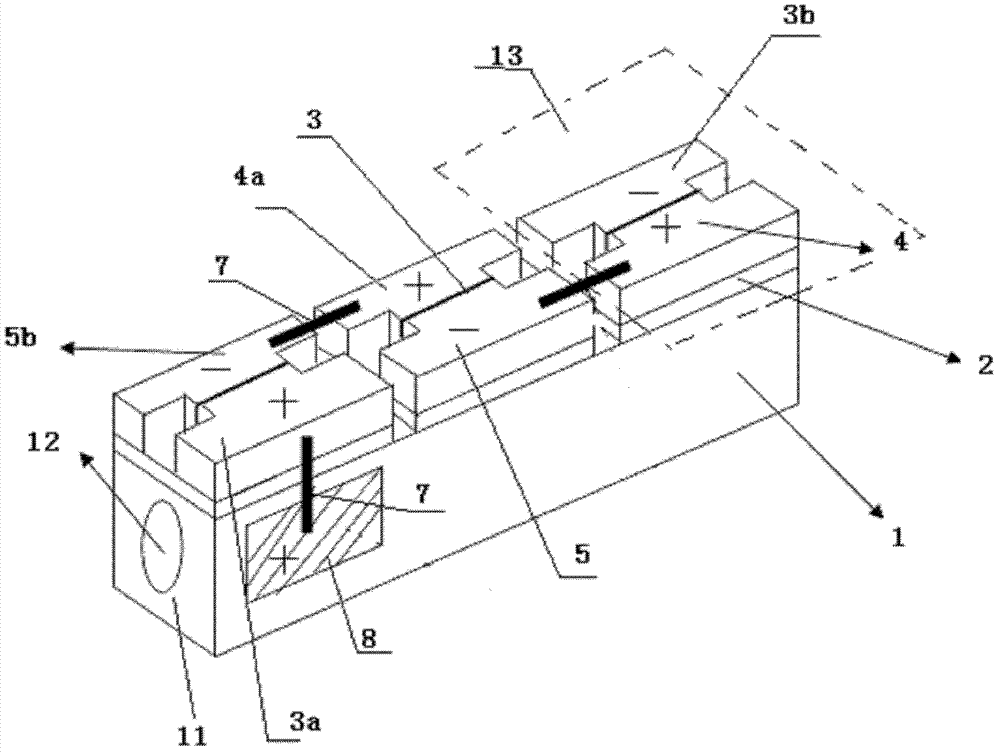

[0044] Such as Figure 2-5 shown.

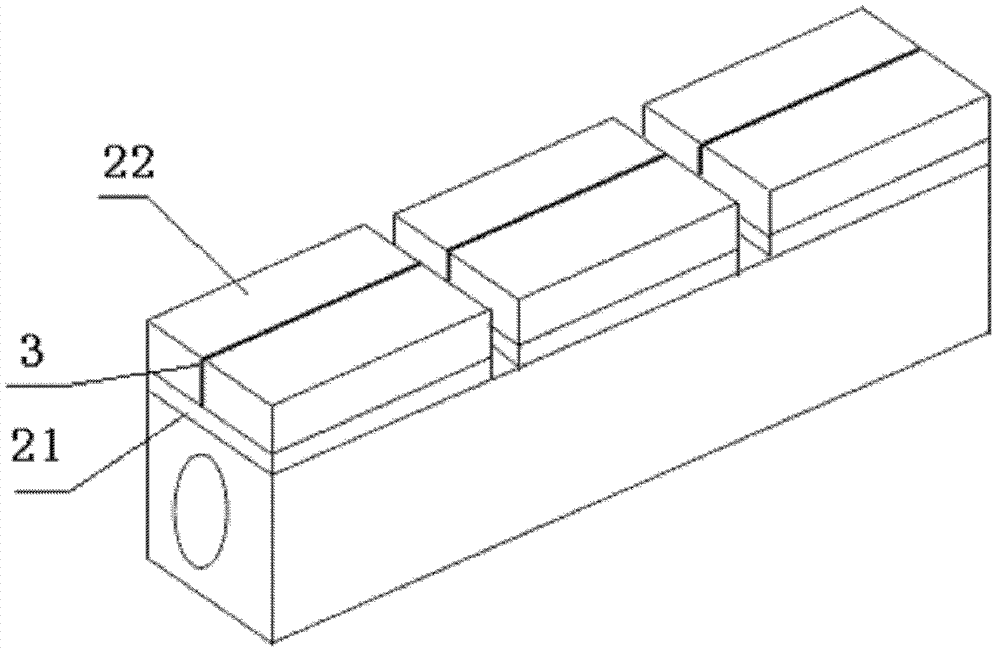

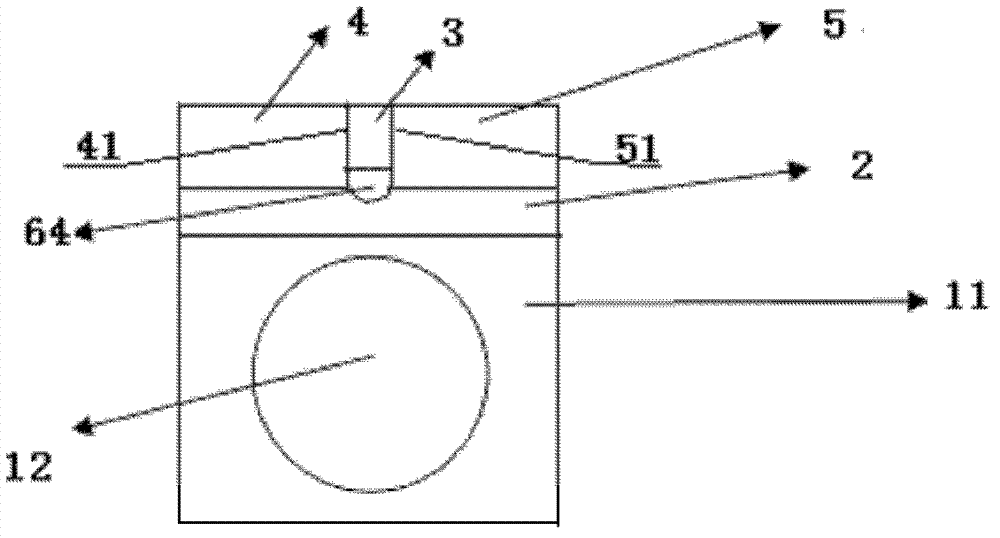

[0045] A packaging structure for a solid-state laser array, including a water-cooling channel 1, an insulating heat-conducting layer 2, a semiconductor laser bar 3, a positive electrode heat sink 4, and a negative electrode heat sink 5; on the water-cooling channel 1, there are three insulating heat-conducting heat sinks arranged at equal intervals Layer 2, a patterned metal layer 6 is provided on the upper surface of each insulating and heat-conducting layer 2, and a metal layer is provided on the lower surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com