Synergistic device for desulfurization absorption tower

A technology for desulfurization absorption towers and regulating devices, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, and can solve problems such as large slurry flow resistance, flue gas escape, and increased possibility of flue gas bypass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

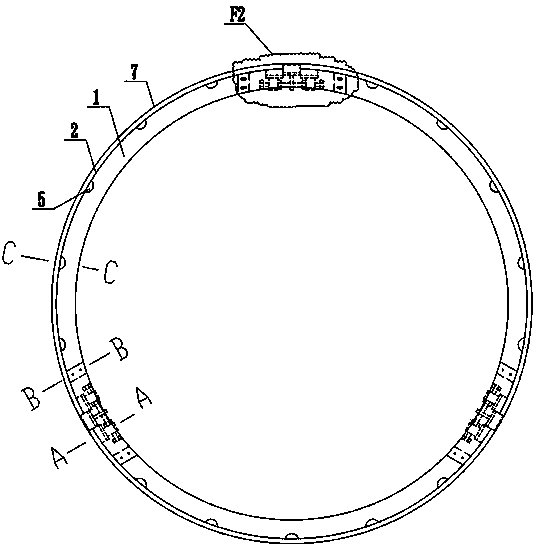

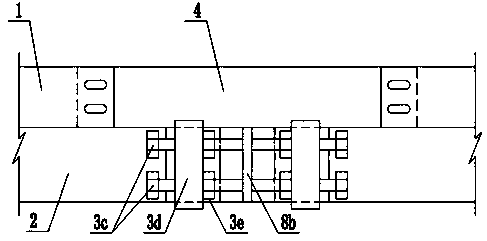

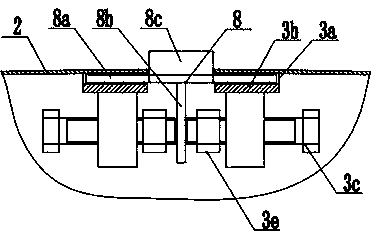

[0029] As shown in the figure, it is a synergistic device for desulfurization absorption tower. In the desulfurization absorption tower, a group of ring hoops 2 are installed on the section perpendicular to the flue gas flow under the spray layer. A group of ring hoops 2 generally adopts 3 sections or 3 sections. above paragraphs, figure 1 , figure 2 The structure shown is the butt joint of three ring-shaped hoops 2; the upper part of each ring-shaped hoop 2 is obliquely connected with an air distribution cone plate 1, such as figure 1 , Figure 7 , Figure 8 As shown, the angle α between the air distribution cone 1 and the horizontal plane is 30° to 70°, the width L of the air distribution cone 1 is 150mm to 500mm, and the thickness is not more than 6mm. The flow resistance of the flue gas in the tower is the basic principle. The preferred width L for the design of the gas distribution cone plate 1 is 250±50mm, the thickness is 3±1mm, and the angle α with the horizontal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com