A multi-drum constant speed and constant tension hydraulic winch

A hydraulic winch, constant tension technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of inability to provide stable speed accurately and uniformly, unfavorable load smooth movement, complex structure of the winch, etc., and achieve volume reduction. , the effect of constant tension and speed, and compact structure of the winch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

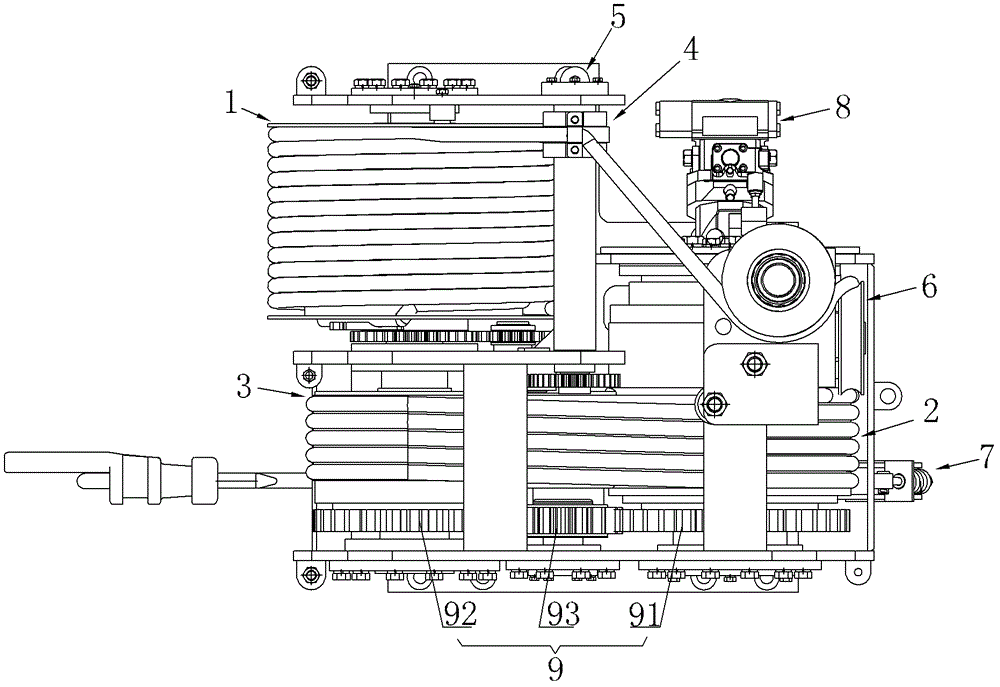

[0033] refer to figure 1 , a multi-drum constant-speed constant-tension hydraulic winch of the present invention includes a rope storage drum 1 for storing wire ropes, a large friction drum 2, a small friction drum 3 and a power source 8 for driving the large friction drum 2, the rope storage drum 1 and the The small friction drum 3 is coaxially arranged, and the steel wire ropes on the large friction drum 2 and the small friction drum 3 are all wound in a single layer to achieve constant tension output. The transmission mechanism 9 that small friction drum 3 rotates at the same linear speed. The power source 8 is mainly a hydraulic motor, and a speed reducer is arranged inside the large friction drum 2, and the output torque of the hydraulic motor is amplified by the speed reducer and then transmitted to the large friction drum 2.

[0034] The transmission mechanism 9 includes a driving gear 91 driven by the large friction roller 2 , a driven gear 92 linked with the small fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com