Methanol synthesis process, methanol synthesis system

A methanol synthesis, methanol technology, applied in the chemical industry, the preparation of hydroxyl compounds, the preparation of organic compounds and other directions, can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

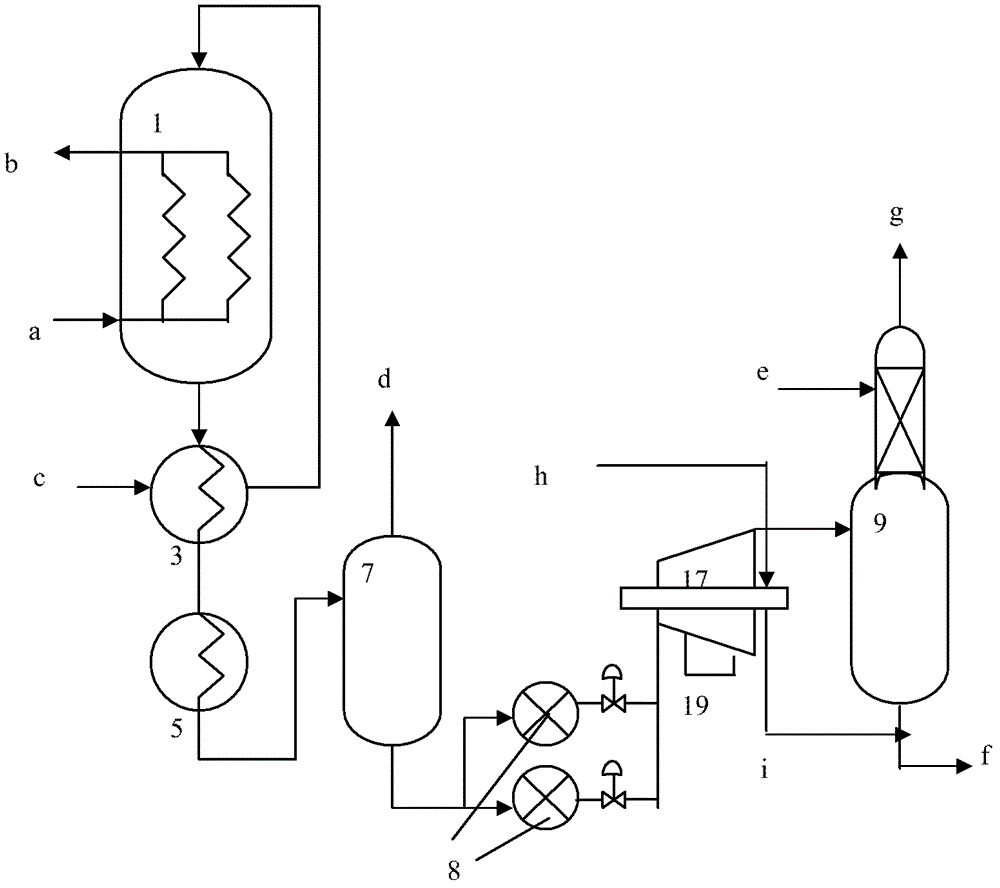

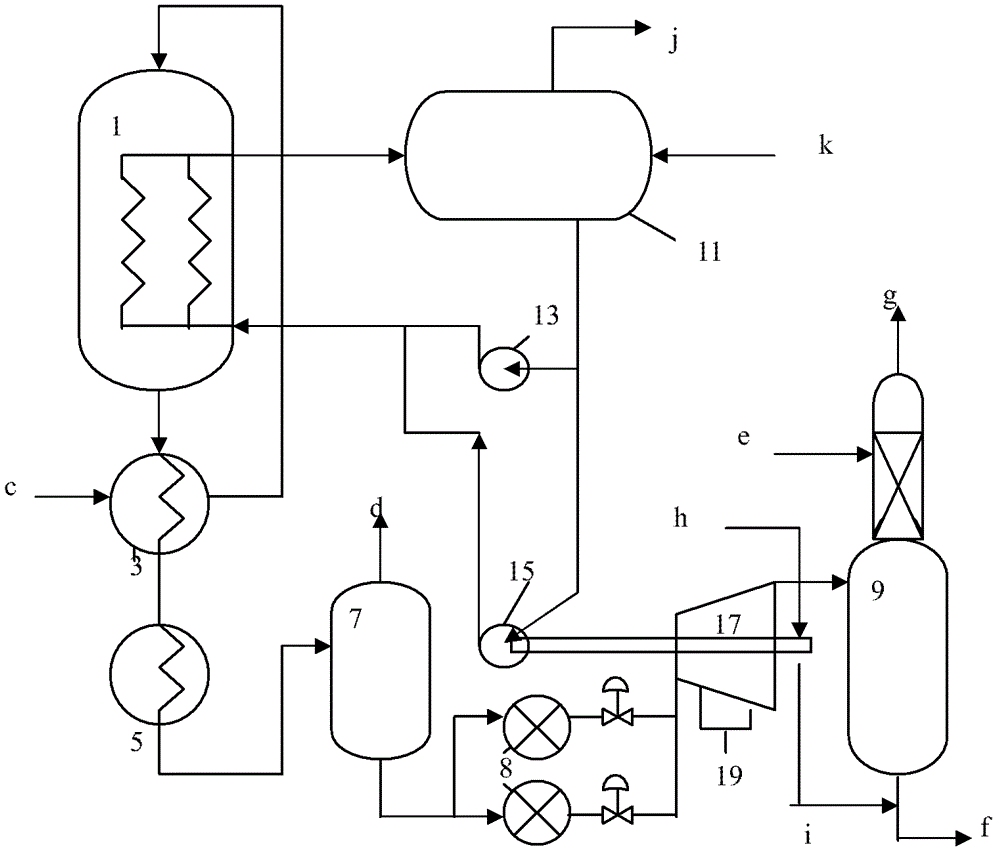

[0053] see figure 2 The first embodiment of the methanol synthesis system of the present invention is described, which includes: a methanol high-pressure separator 7 , a methanol flash tank 9 and a hydraulic turbine 17 . The hydraulic turbine 17 has a working medium inlet and a working medium outlet. The methanol at the separation place of the methanol high-pressure separator 7 enters from the working medium inlet and is finally discharged from the working medium outlet. The main shaft of the hydraulic turbine 17 is used to drive the turbine converted into mechanical energy output. The working medium inlet of the hydraulic turbine 17 communicates with the methanol outlet of the methanol high-pressure separator 7 , and the working medium outlet of the hydraulic turbine 17 communicates with the inlet of the methanol flash tank 9 . continue to see figure 2 , a filter 8 can also be set on the communication pipeline between the methanol outlet of the methanol high-pressure sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com