High-bearing-capacity micro-settlement shearing resistant prestressed pipe pile and design and construction methods thereof

A prestressed pipe pile and bearing capacity technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of mud pollution, long construction period and high construction cost, and achieve the effect of clean site, reduced construction period and reduced construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

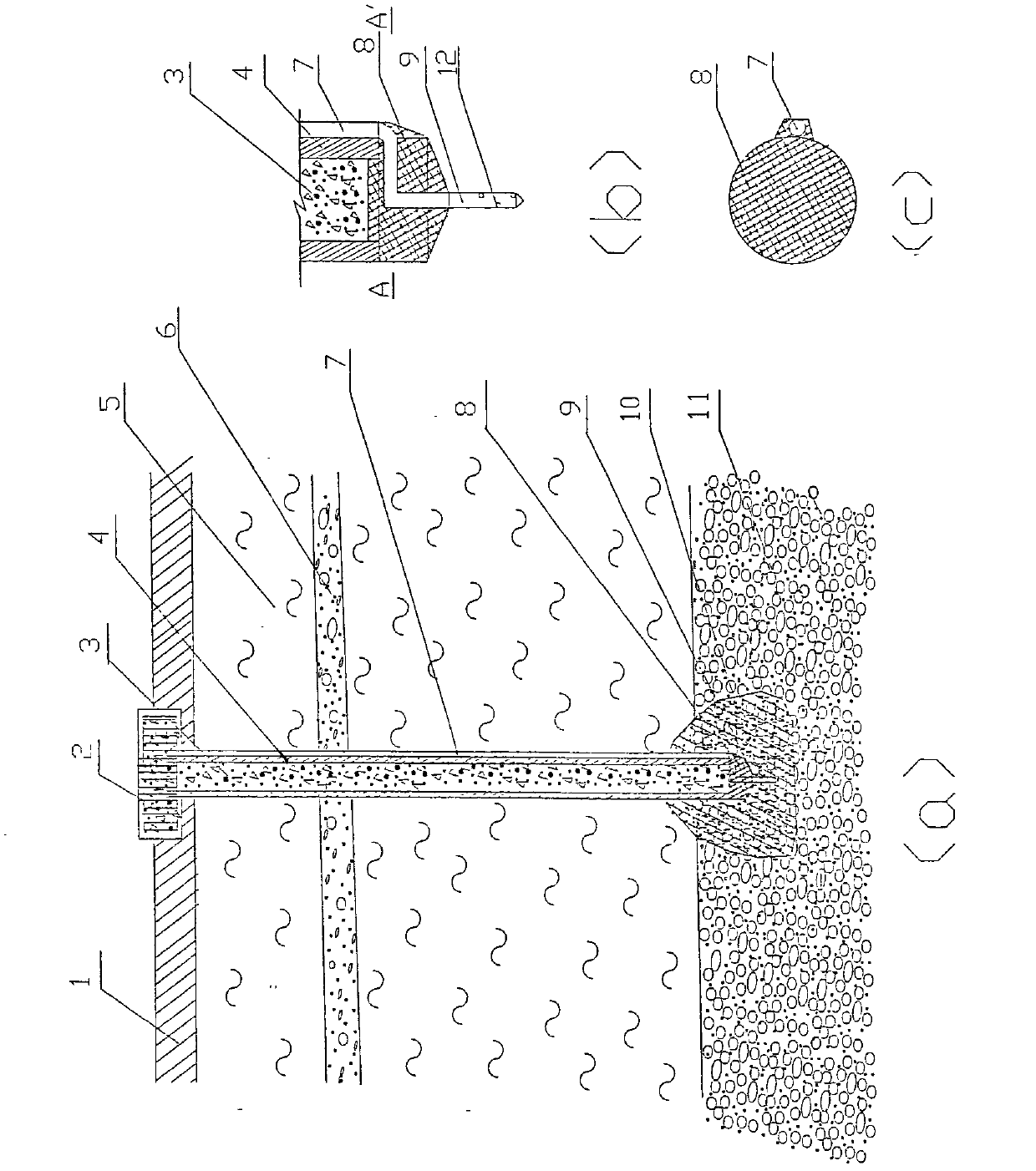

[0022] A typical embodiment of the present invention is as follows figure 1 , a construction method of micro-settlement shearing prestressed pipe pile with high bearing capacity is:

[0023] ①. A steel casing with a diameter slightly larger than the diameter of the pipe pile is buried on the ground pile position to avoid the collapse of the surface miscellaneous fill;

[0024] ②. Use a long auger drill or a simple drill to guide the hole: dig out the silt and gravel from the casing until the interlayer of gravel or gravel is dug through or close to it;

[0025] 3. Use a long auger to lead the hole, when digging through or close to digging through the pebble and gravel interlayer, inject mud from the center of the auger pipe to mix it or transport it out of the bored pile construction site to fill the hollowed out part of the pebble and gravel layer with thick mud to avoid The pebble and gravel layer collapses; when a simple drilling rig is used to guide the hole, when the peb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com