Pressurizer oil incoming pipe

An oil inlet pipe and supercharger technology, which is applied to machines/engines, lubricant conduit devices, engine components, etc., can solve problems such as damage, corrosion and aging of oil inlet pipes, reduce costs, reduce damage probability, and improve use safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

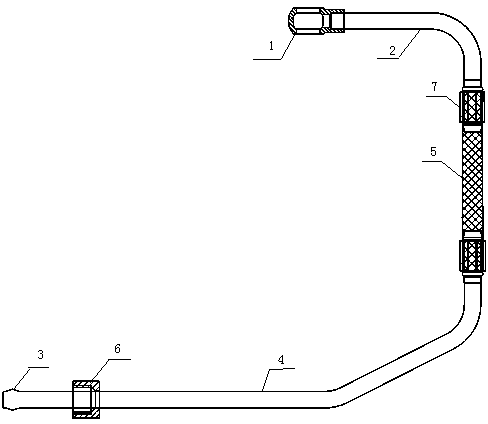

[0017] like figure 1 As shown, the turbocharger oil inlet pipe disclosed by the present invention includes a ball joint 1, a metal pipe I2 with a thread at one end, a metal pipe II4 with a snap ring 3 at one end, a connecting hose 5, a bolt 6 with a cover at one end, and a buckle The sleeve 7, the cover of the bolt 6 is provided with a through hole compatible with the outer di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com