Light fast-response electromagnetic valve

A fast-response, solenoid valve technology, applied in the field of solenoid valves, can solve the problems of increased structural weight and inability to meet the needs of lightweight and miniaturized control valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

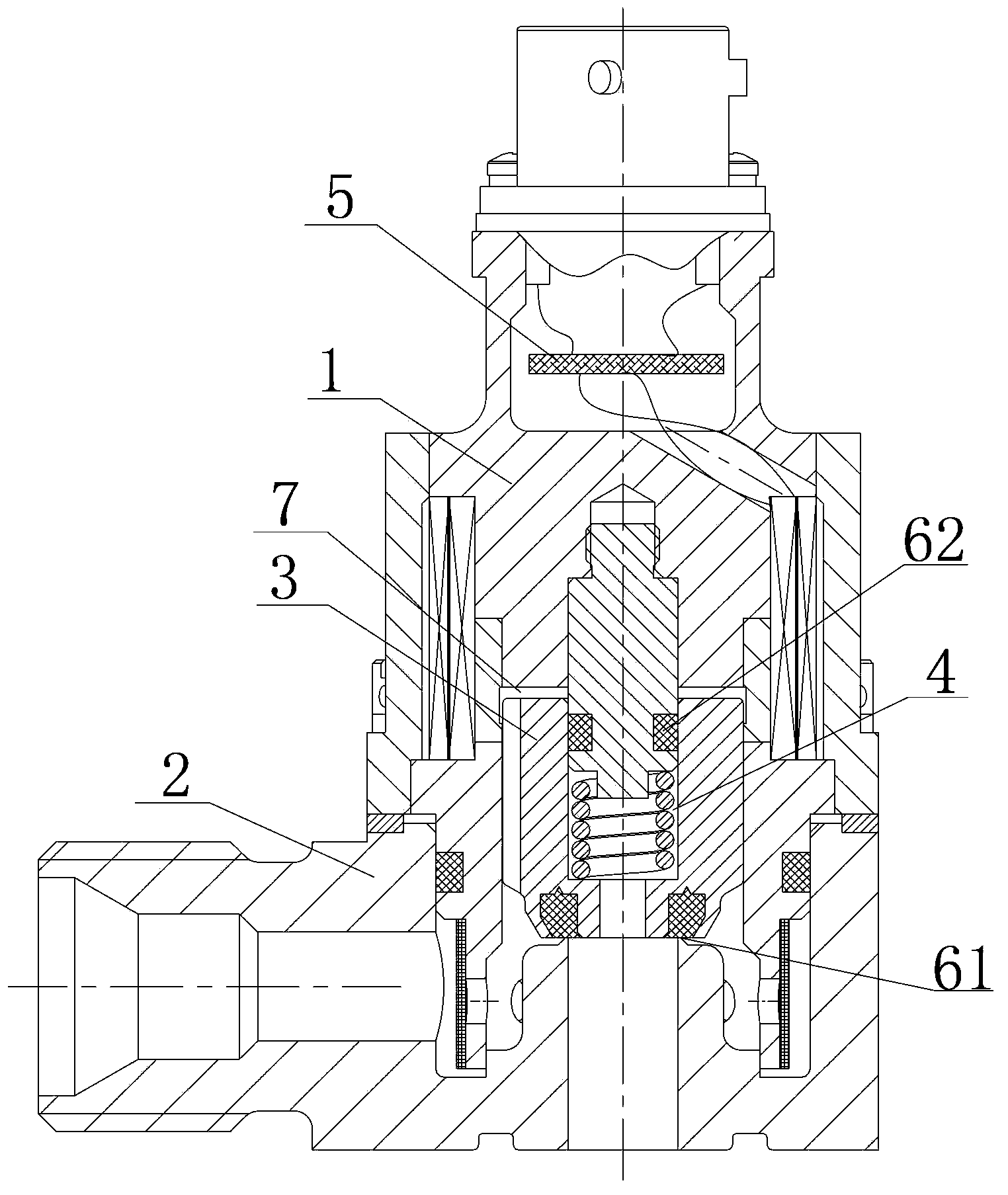

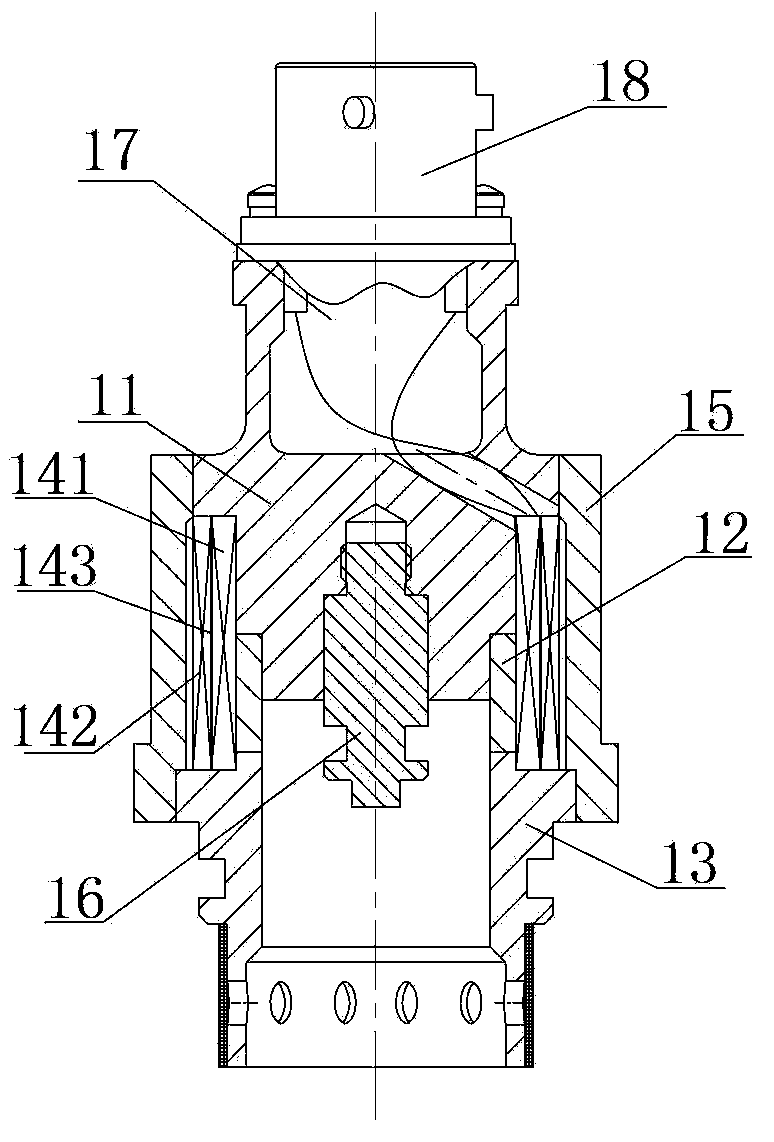

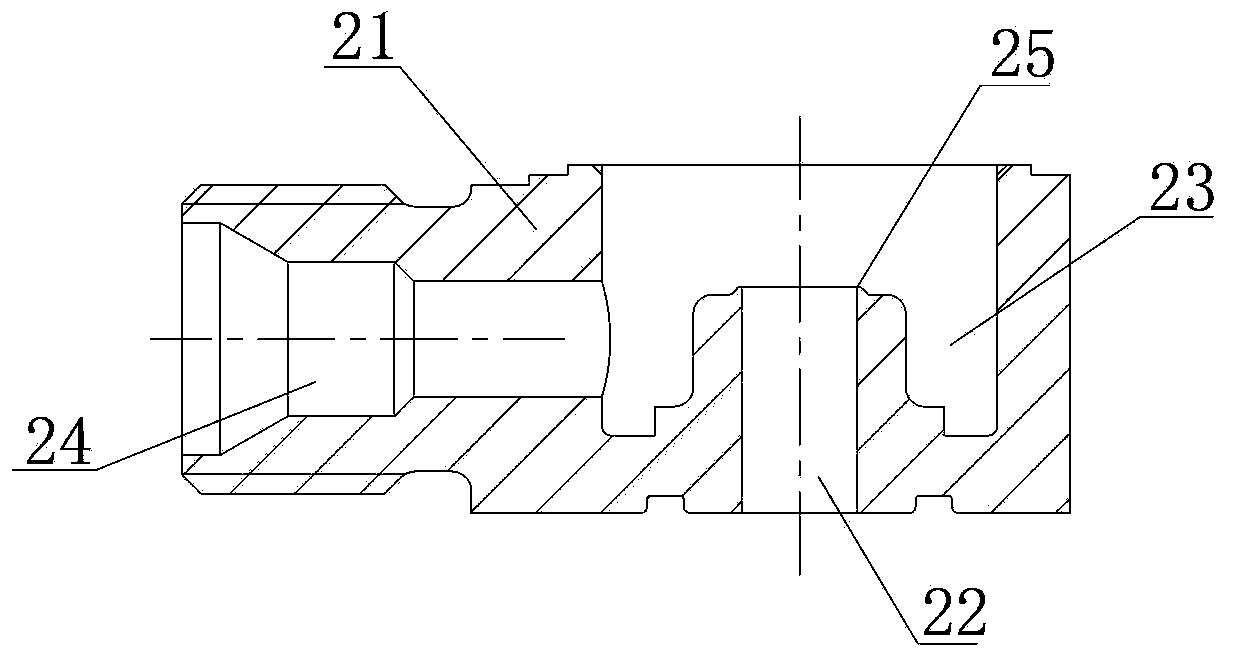

[0034] The implementation example applied to a hydraulic control system is as follows:

[0035] A hydraulic control system uses a fast-response solenoid valve with a built-in chip drive circuit. According to the design requirements, the working medium of the system is green dinitrogen tetroxide, a strong oxidizing medium, the medium pressure is 2MPa, the system control voltage is 28V, and the flow rate is 30g / s. The test shows that, without an external control circuit, the opening time of the solenoid valve is 5ms, the closing time is 2ms, the flow resistance is 0.2MPa when the flow rate is 30g / s, and the weight of the solenoid valve is 0.15kg.

[0036] The valve is remotely controlled by electrical signals, and has excellent performances such as small size, light weight, good sealing, fast switching speed, and low power consumption. The corrosion resistance of the solenoid valve can be improved by selecting corrosion-resistant soft magnetic materials, metal matrix materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com