Teflon rubber covered roller

A polytetrafluoroethylene rubber roller and polytetrafluoroethylene technology, which is applied to shafts and bearings, can solve problems such as increasing processing difficulty, and achieve the effects of overcoming short service life, broad market prospects and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

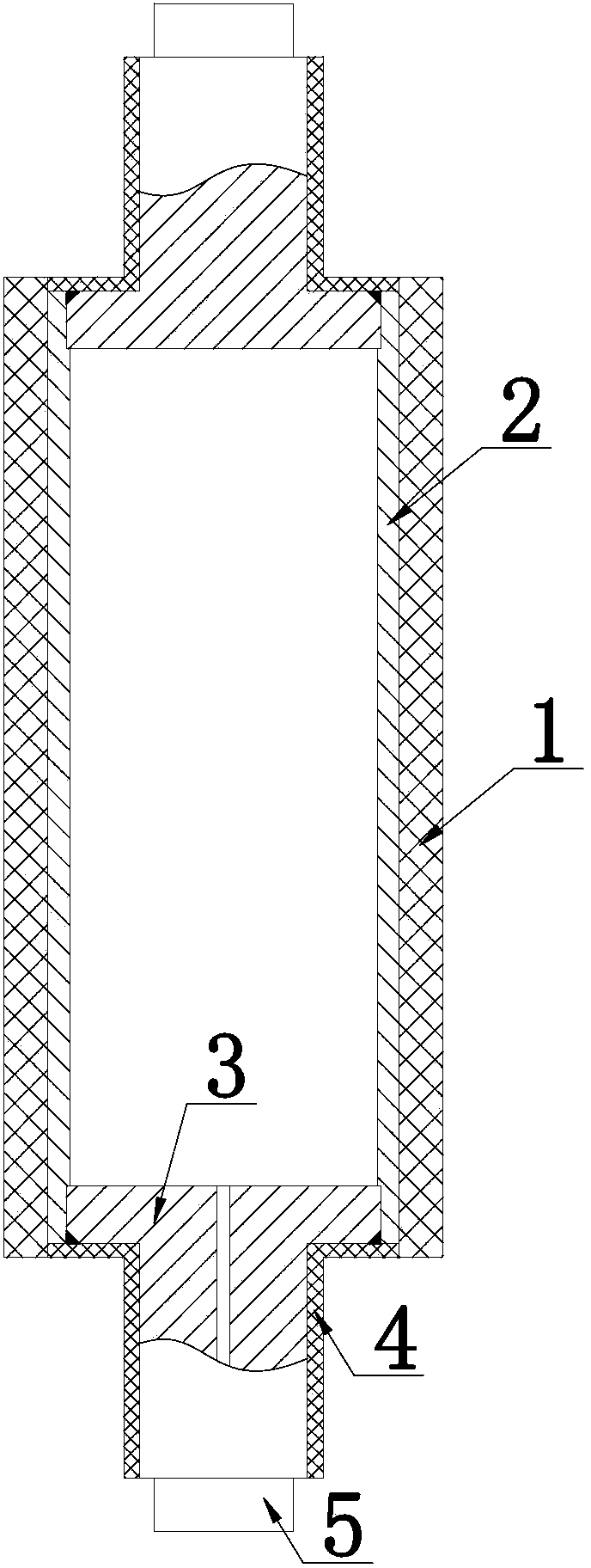

[0017] Such as figure 1 The polytetrafluoroethylene rubber roller shown, the rubber roller includes a roller body and a metal mandrel, the roller body adopts a cylindrical sleeve 1 made of polytetrafluoroethylene, the wall thickness of the sleeve 1 is 30mm, and the metal core The rod is installed in the sleeve 1 and fixed with the sleeve 1. The surface of the metal mandrel is provided with saber teeth in the axial direction, and the metal mandrel and the sleeve 1 are tightly fitted and fixed by the saber teeth. The metal mandrel includes a metal pipe body 2 and a connecting end 3, the wall thickness of the metal pipe body 2 is 20 mm, the metal pipe body 2 is set in the casing 1, and the connecting end 3 is set in the The two ends are welded with the inner wall of the metal pipe body 2, the connecting end 3 is provided with a sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com