Dust-proofing thin film assembly

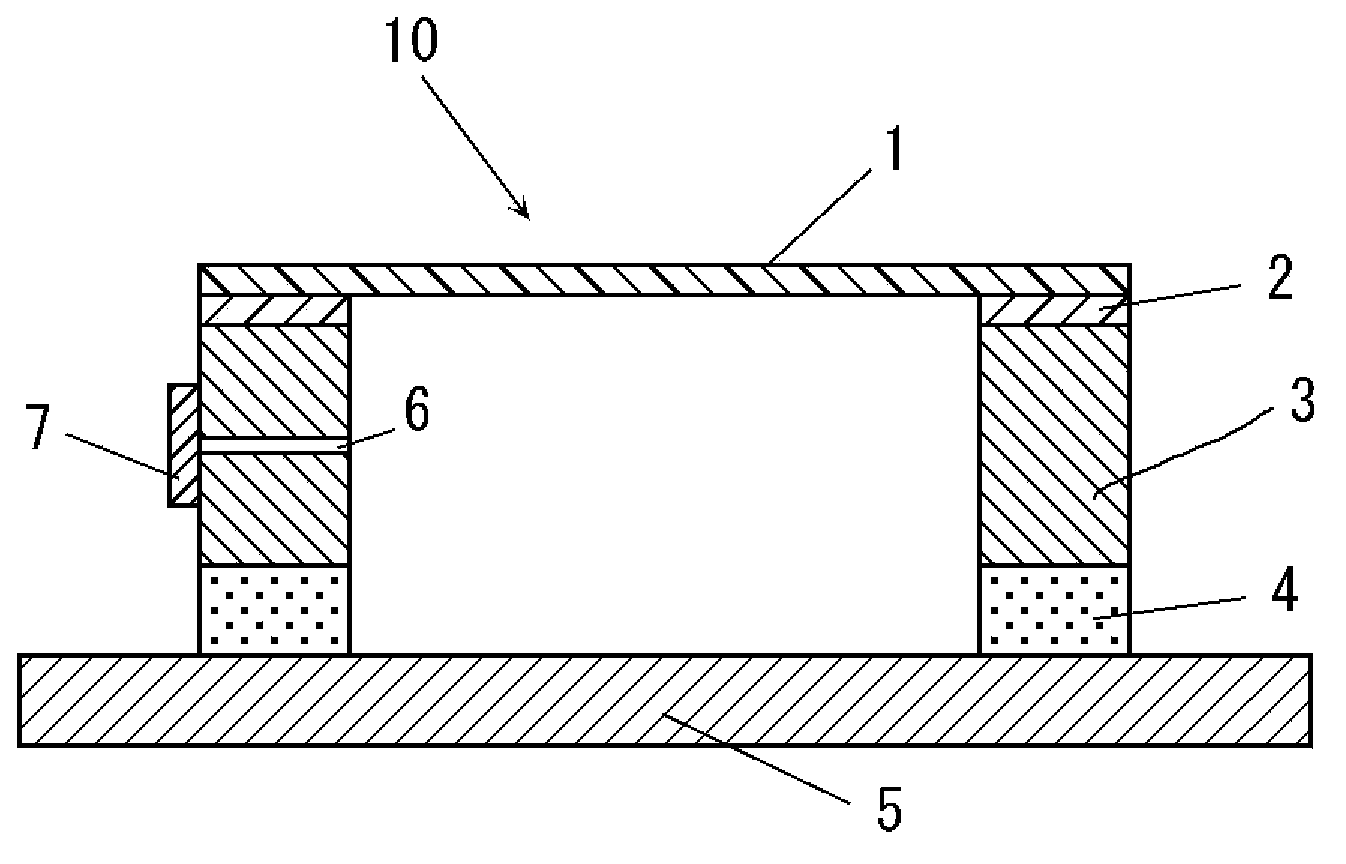

A dust-proof film component and a technology of dust-proof film, which are applied to the original parts, optics, instruments, etc. for photomechanical processing, and can solve the problems of photomask damage and adhesive layer being easily crushed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

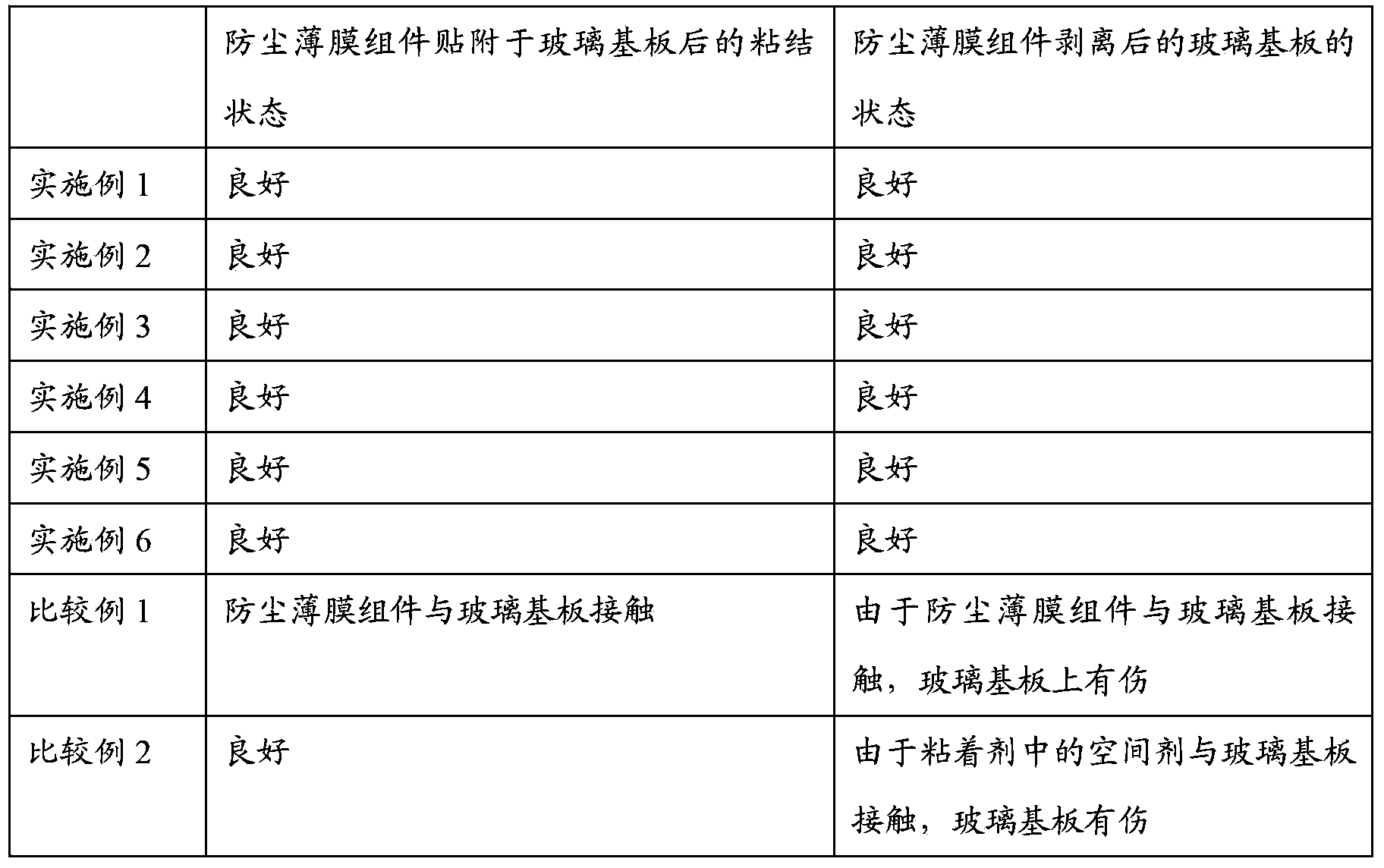

[0056] A rectangular aluminum alloy frame with an outer dimension of 782×474mm, an inner dimension of 768×456mm, a height of 5.0mm, a radius of 2.0mm on the inside of the corner, and a radius of 6.0mm on the outside is obtained by machining, and is made of SUS beads. After sandblasting to obtain a rough surface with Ra of 0.5-1.0 μm, black oxide film treatment is carried out.

[0057] Move this frame into a clean room, wash it thoroughly with neutral detergent and pure water, and dry it.

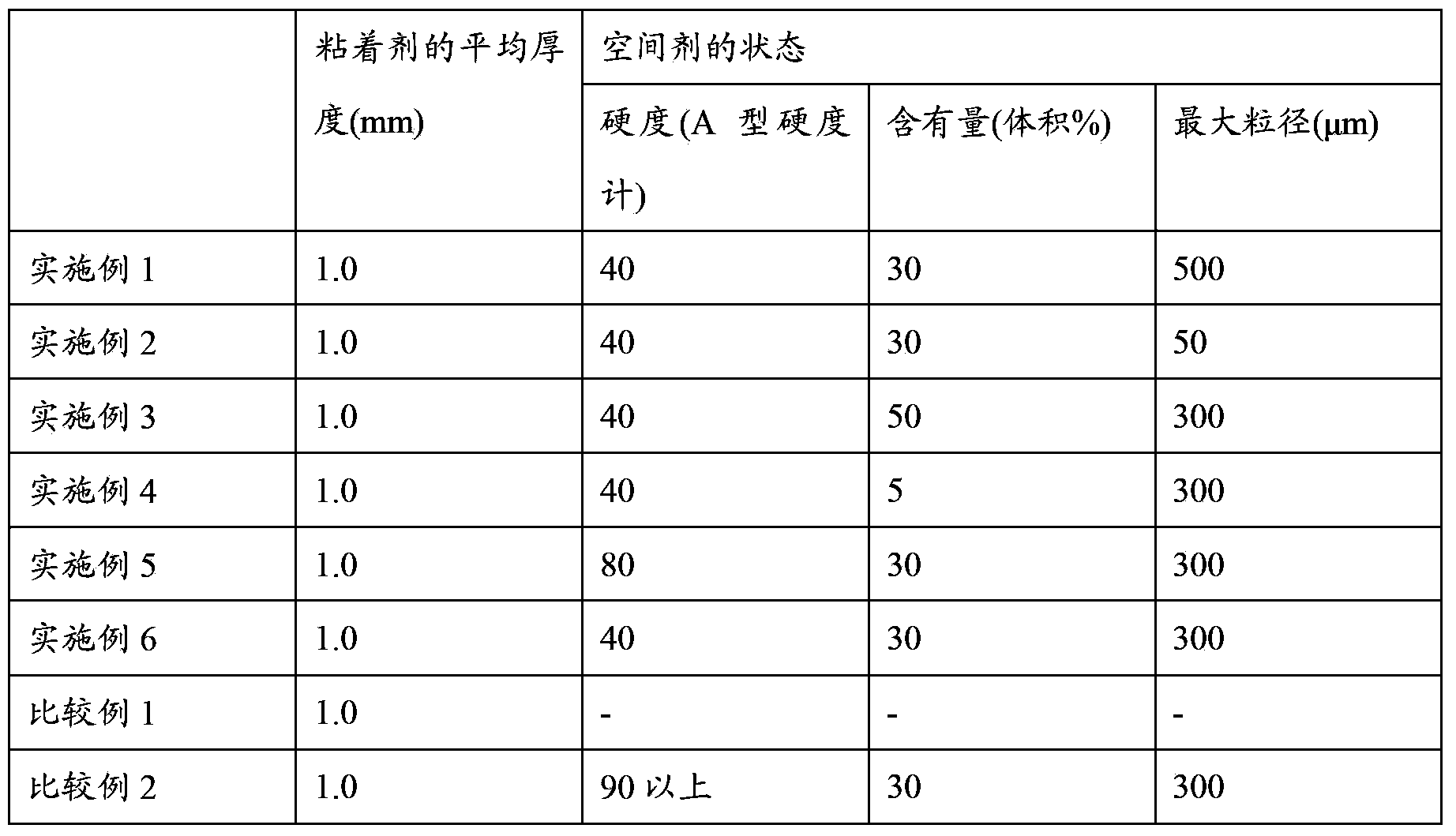

[0058] Then, to silicone resin adhesive X-40-3122 (trade name manufactured by Shin-Etsu Chemical Co., Ltd., hardness: A-type durometer measurement value: 15), silicone rubber powder was added as a spacer. (manufactured by Shin-Etsu Chemical Co., Ltd., maximum particle size: 500 μm, hardness: A-type hardness tester measurement value 40), so that the content was 30% by volume to obtain an adhesive containing a spacer.

[0059] In addition, the hardness of the space agent was measured after be...

Embodiment 2

[0063] In the silicone resin adhesive X-40-3122, silicone rubber powder X-52-875 (manufactured by Shin-Etsu Chemical Co., Ltd., maximum particle size: 50 μm, hardness: A-type durometer Measured value 40) was added until it became 30% by volume to obtain an adhesive containing a spacer, and a pellicle was produced in the same manner as in Example 1. The thickness of the adhesive layer is 1.0mm.

Embodiment 3

[0065] Add silicone rubber powder (manufactured by Shin-Etsu Chemical Co., Ltd., maximum particle size: 300 μm, hardness: A-type durometer value 40) as a spacer to the silicone resin adhesive X-40-3122 until its volume becomes 50% by volume to obtain an adhesive containing a spacer. Except for this, a pellicle was produced in the same manner as in Example 1. The thickness of the adhesive layer is 1.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com