Wet-type spent fuel storage system

A spent fuel, wet technology, applied in the field of nuclear power plant spent fuel storage, can solve the problems of poor reliability of the cooling system, achieve reliable operation, and realize the effect of long-term storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to understand the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

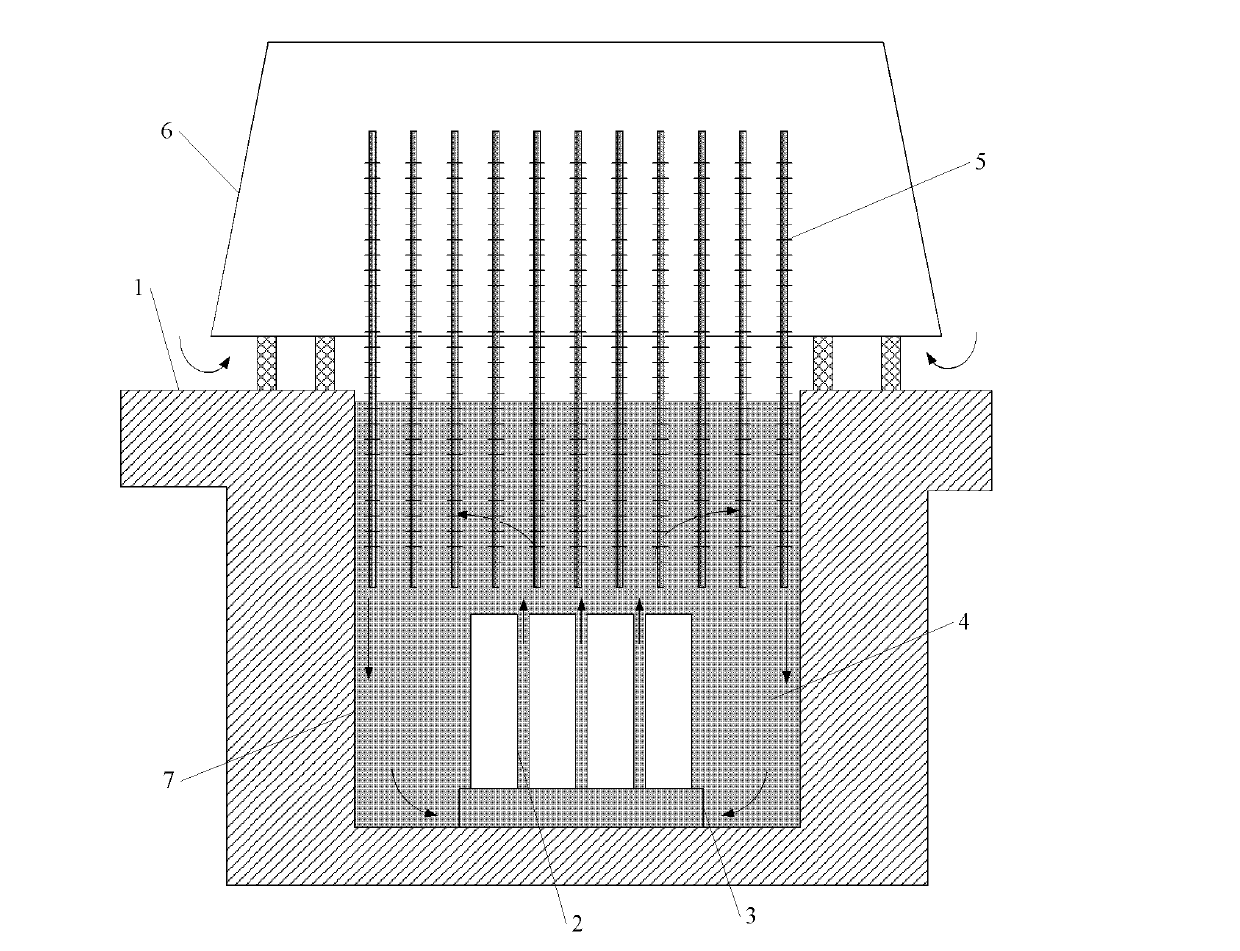

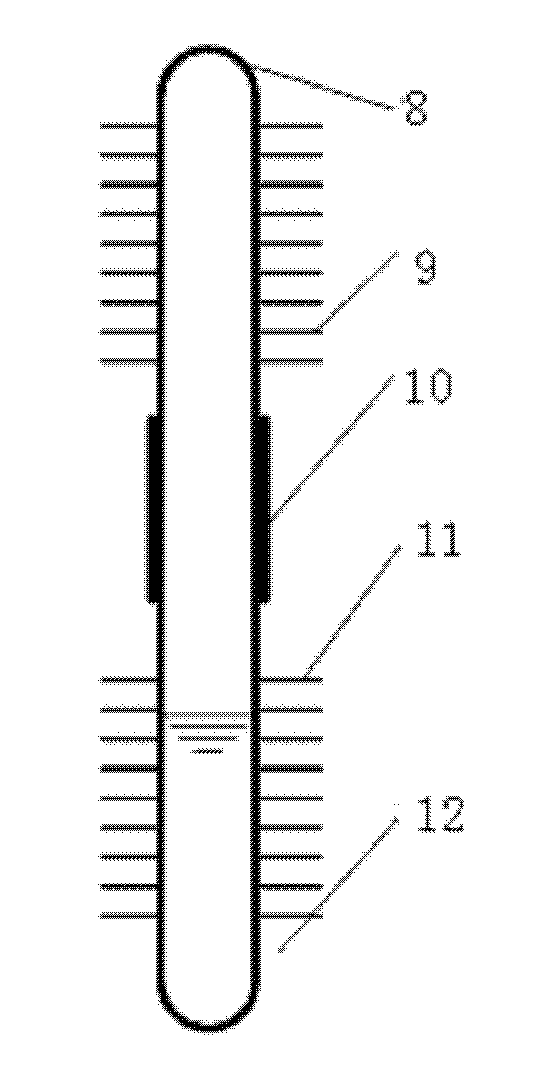

[0012] Such as figure 1 As shown, a wet-type spent fuel storage device includes a sealed container 2, a spent fuel storage grid 3, a cooling liquid 4, a heat pipe cooling device 5, an air cooling tower 6 and a spent fuel storage pool 7, and cement is built under the ground 1 The spent fuel storage pool 7 is used as the spent fuel storage pool 7, and the spent fuel storage pool 7 is filled with a cooling liquid 4, and the cooling liquid 4 is made of cheap water or a lithium bromide liquid that is difficult to volatilize and has a very high boiling point. The spent fuel storage grid 3 is placed at the bottom area of the spent fuel storage pool 7. The spent fuel storage grid 3 adopts the existing technology to meet the requirements of shock resistance and strength and provide sufficient support. The spent fuel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com