Method for selecting lithium battery aluminum plastic films

An aluminum-plastic film, lithium battery technology, applied in battery pack components, circuits, electrical components, etc., can solve the problems of single selectivity, inaccurate selection results, inability to systematically select performance, etc., and achieve accurate selection results. The effect of improving the test effect and shortening the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

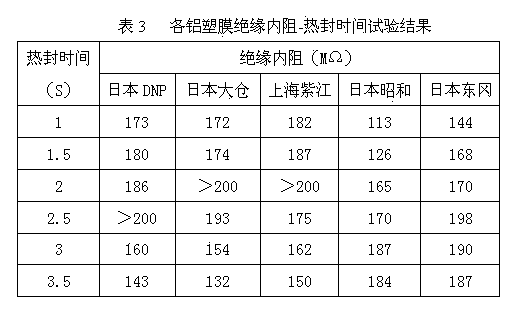

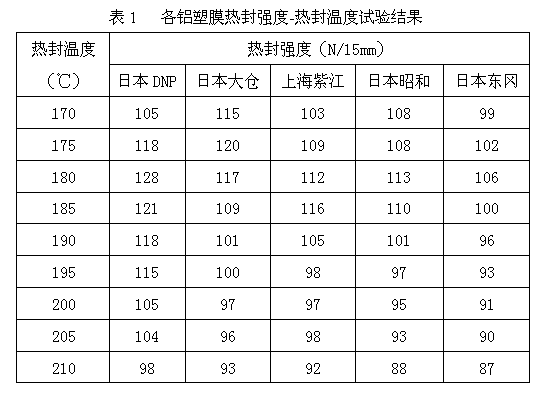

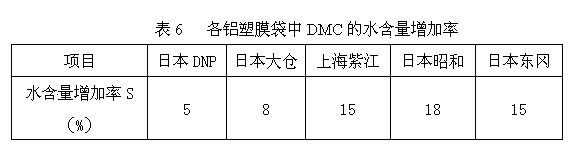

[0036] Choose aluminum-plastic films from five different manufacturers in Japan DNP, Japan Okura, Shanghai Zijiang, Japan Showa, and Japan Higashioka. Under the conditions of heat-sealing pressure of 0.1Mpa and heat-sealing time of 1S, each aluminum-plastic film is tested separately. Carry out a single factor test of heat-sealing temperature, measure the heat-sealing strength with a tensile machine after heat-sealing, and obtain the heat-sealing strength-heat-sealing temperature test results of the aluminum-plastic film as shown in Table 1. When the heat-sealing temperature is 170°C, Under the condition that the time is 1S, the single factor test of heat sealing pressure is carried out for each aluminum plastic film, and the heat sealing strength is measured with a tensile machine after heat sealing. The obtained aluminum plastic film heat sealing strength - heat sealing pressure test results are shown in Table 2 It shows that under the conditions of heat-sealing pressure of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com