Enhanced flue gas damper mixing device

A mixing device and flue gas technology, which is applied in exhaust gas devices, gas and gas/steam mixing, mixers, etc., can solve problems such as expensive and increased system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

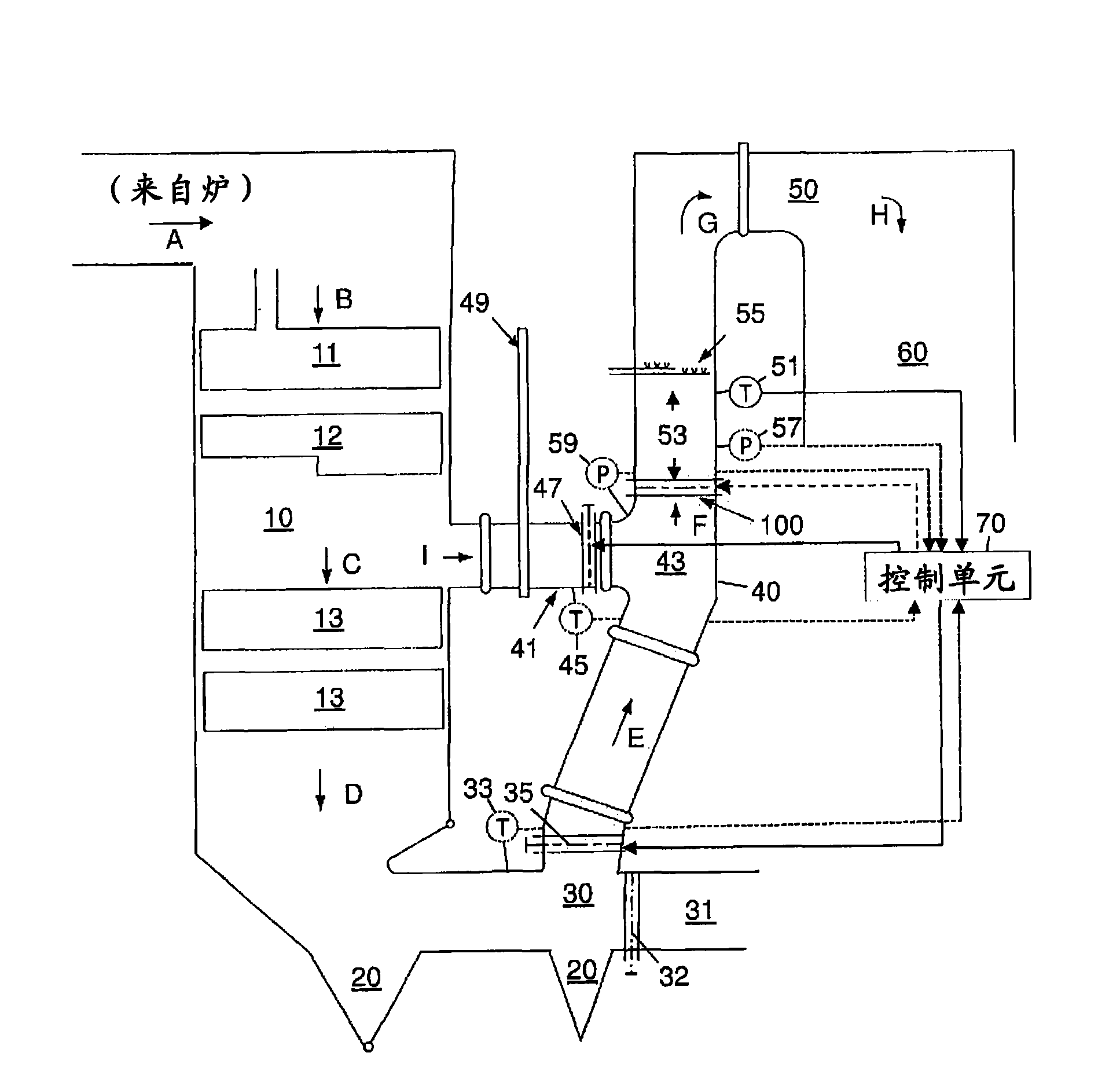

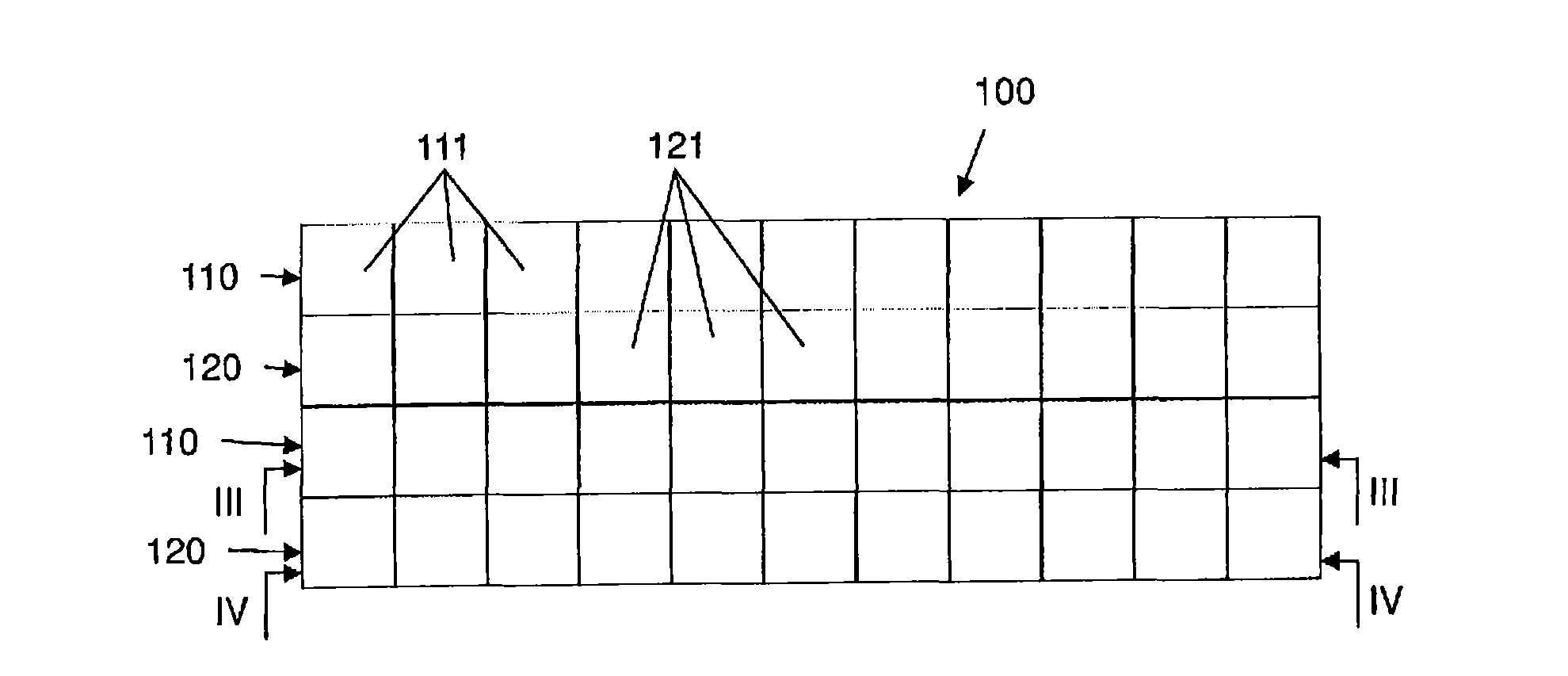

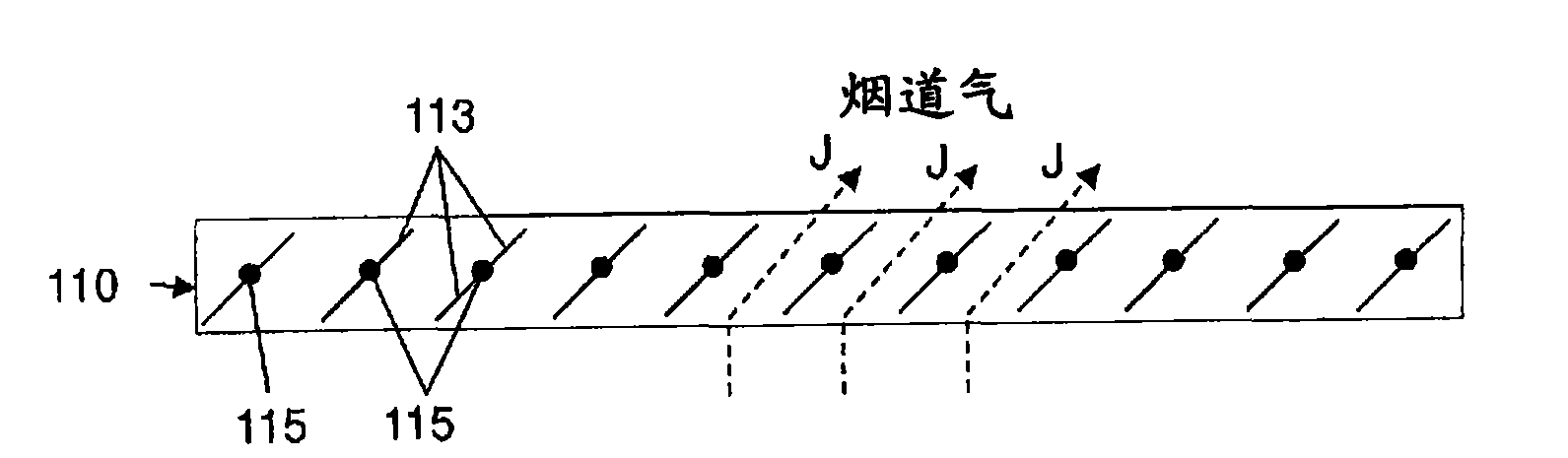

[0031] When the boiler is operating near full capacity, there is little or no gas flow through the bypass, there is effectively only a single gas flow and no mixing is required. As the boiler load decreases, an increasing amount of flue gas must bypass the economizer to maintain the correct flue gas temperature, thereby creating two distinct gas streams. Gas mixing is only required when there are at least two gas streams to be mixed. Prior art designs do not differentiate between different boiler loads and are not adjustable. They therefore have non-adjustable mixers that create a pressure drop at all boiler loads, where the highest pressure drop is created at the highest boiler load where no mixing is required.

[0032] The present invention provides minimal pressure drop when there is effectively only a single gas stream flowing. It is also adjustable to optimize mixing and minimize back pressure across the entire operating range of the steam generator.

[0033] It employ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com