Thin-stone combined heat-insulating decorative board, as well as production and mounting methods thereof

A composite thermal insulation and decorative board technology, applied in the field of building decoration materials, can solve the problems of labor-intensive labor, labor intensive work, hidden dangers of engineering safety, etc., and achieve the effects of convenient construction, scientific structure, and reasonable stress structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

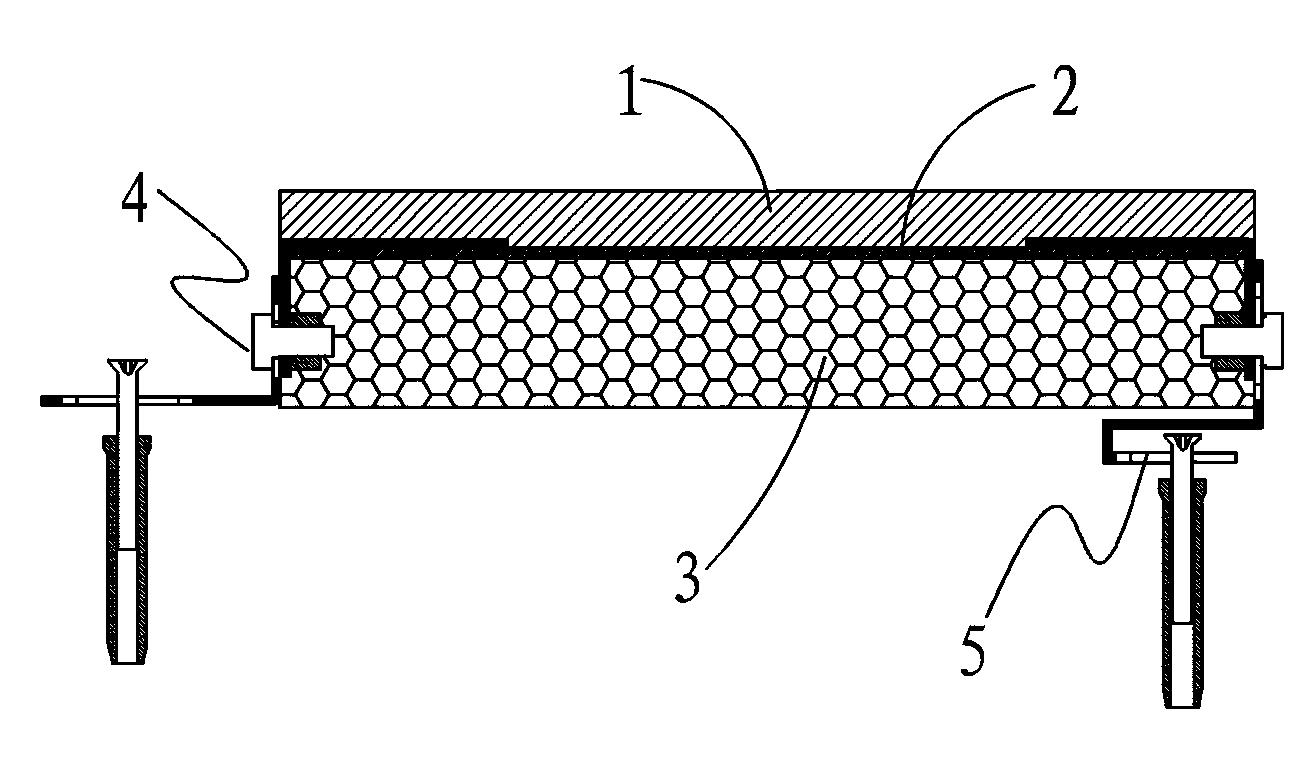

[0029] Such as Figure 1 to Figure 3 As shown, a thin stone composite thermal insulation decorative board includes a decorative stone board 1, a grade A fireproof thermal insulation material board 3, a polymer inorganic adhesive 2, an upper metal pendant combination 4 and a lower metal pendant combination 5, and the polymer inorganic The adhesive 2 is used to bond the decorative stone board 1 and the A-class fireproof insulation material board 3; the upper end and the lower end of the decorative stone board 1 are provided with " ” shaped 45° chute.

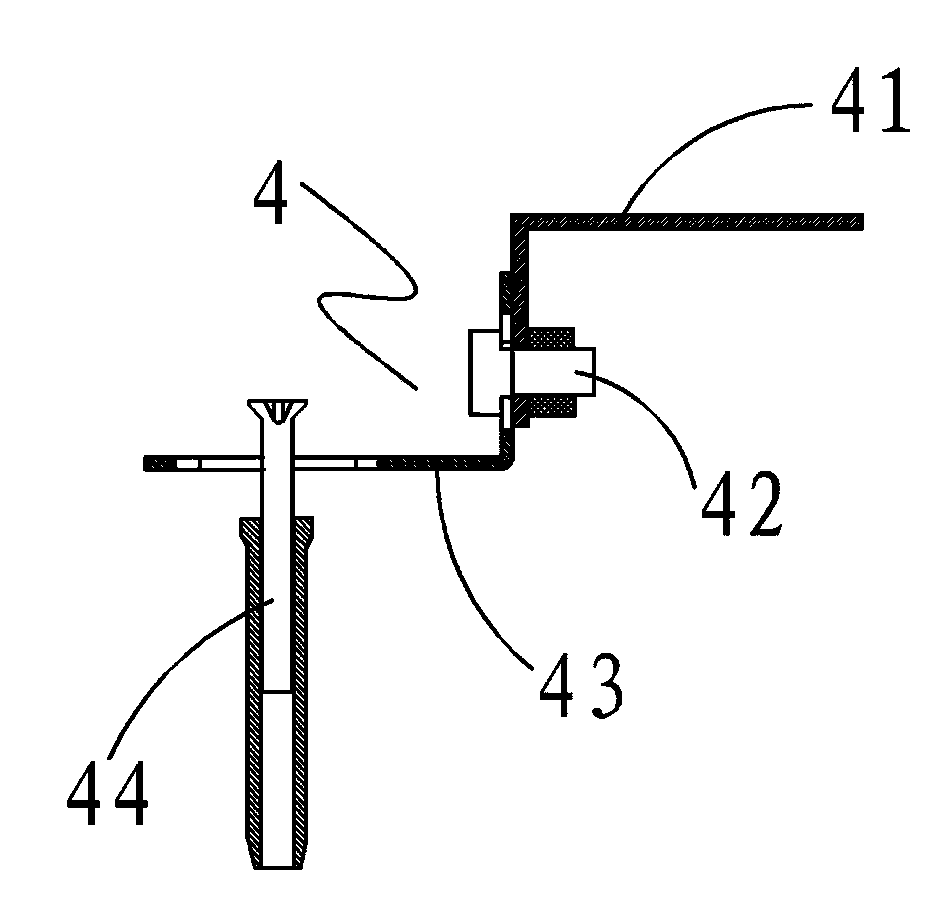

[0030] Such as figure 2 As shown, the upper metal pendant combination 4 is mainly composed of an embedded metal pendant 41, an upper connecting pendant 43, an expansion bolt 44 installed on the upper connecting pendant 43, and is used to connect between the embedded metal pendant 41 and the upper connecting pendant 43. The bolt 42 of fastening action is formed.

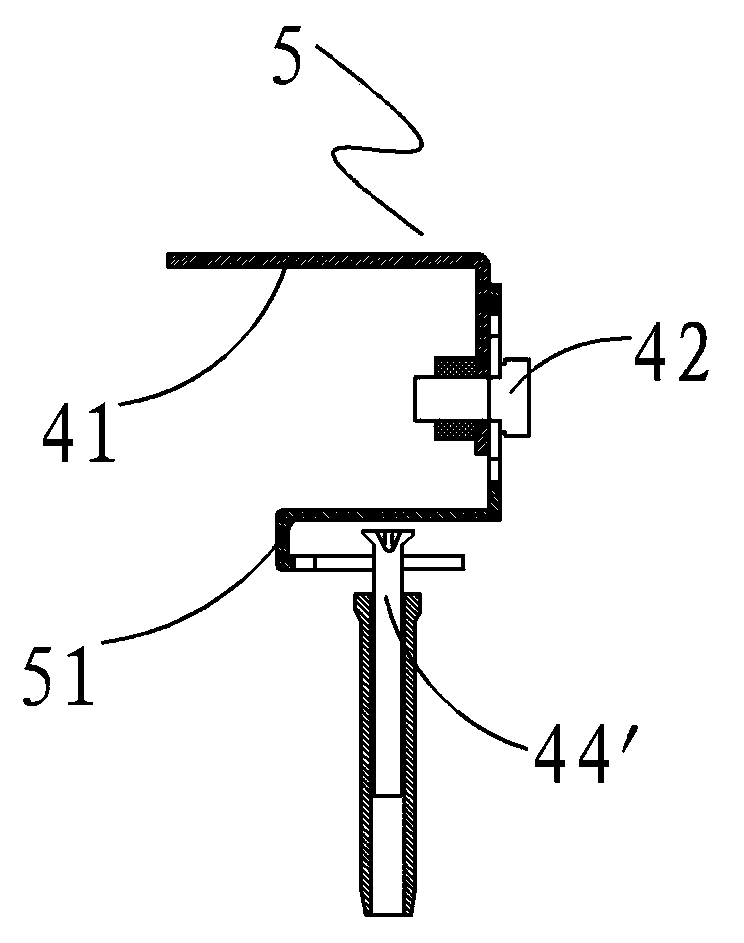

[0031] Such as image 3 As shown, the lower metal pendant comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com