Oil supply control lubrication system for gearbox

A lubrication system and oil supply control technology, applied in the direction of gear lubrication/cooling, etc., can solve the problems of hydraulic transmission box structure size increase, large external size, oil and gas leakage, etc., to avoid oil leakage and pollution of hydraulic oil, Effects of reduced external dimensions and reduced power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

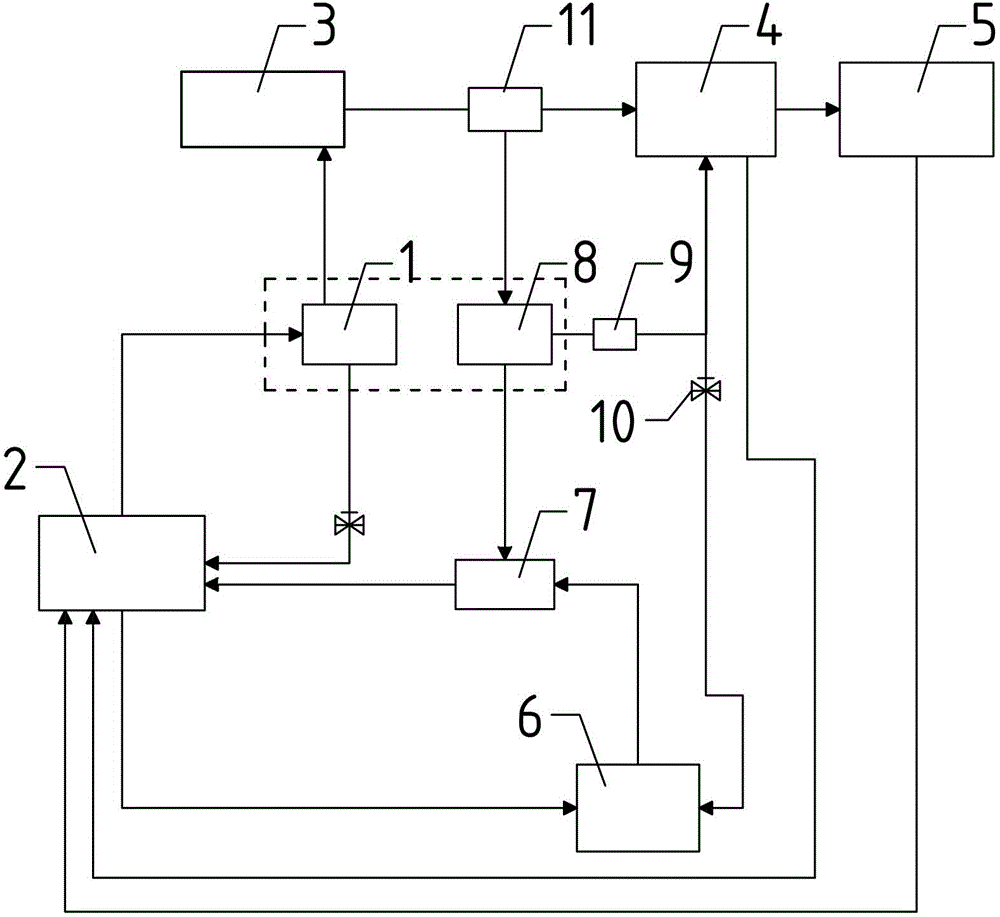

[0021] Such as figure 1 The oil supply control lubrication system for the transmission box shown includes: oil supply pump 1, oil tank 2, heat dissipation system 3, main control valve 4, hydraulic component 5, inert pump 6 and lubrication system 7, and also includes: control pump 8;

[0022] The oil supply pump 1 draws hydraulic oil from the oil tank 2 and sends it to the heat dissipation system 3 through a pipeline, and the oil returned to the mailbox by the oil supply pump 1 communicates with the mailbox 2 through a pipeline with a one-way valve;

[0023] The heat dissipation system 3 passes the filter 11 through the pipeline to transport the cooling hydraulic oil back to the transmission box and then enters different oil paths. One is directly into the hydraulic element 5 to participate in the transmission of power, and the other is to connect to the oil supply pipeline of the control pump 8. Furthermore, it is ensured that the incoming oil of the control pump 8 is pressure oil,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com