Milling cutter for hard machining

A milling process and milling cutter technology, applied in the field of milling cutters, can solve problems such as tool failure, high cutting edge, and uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

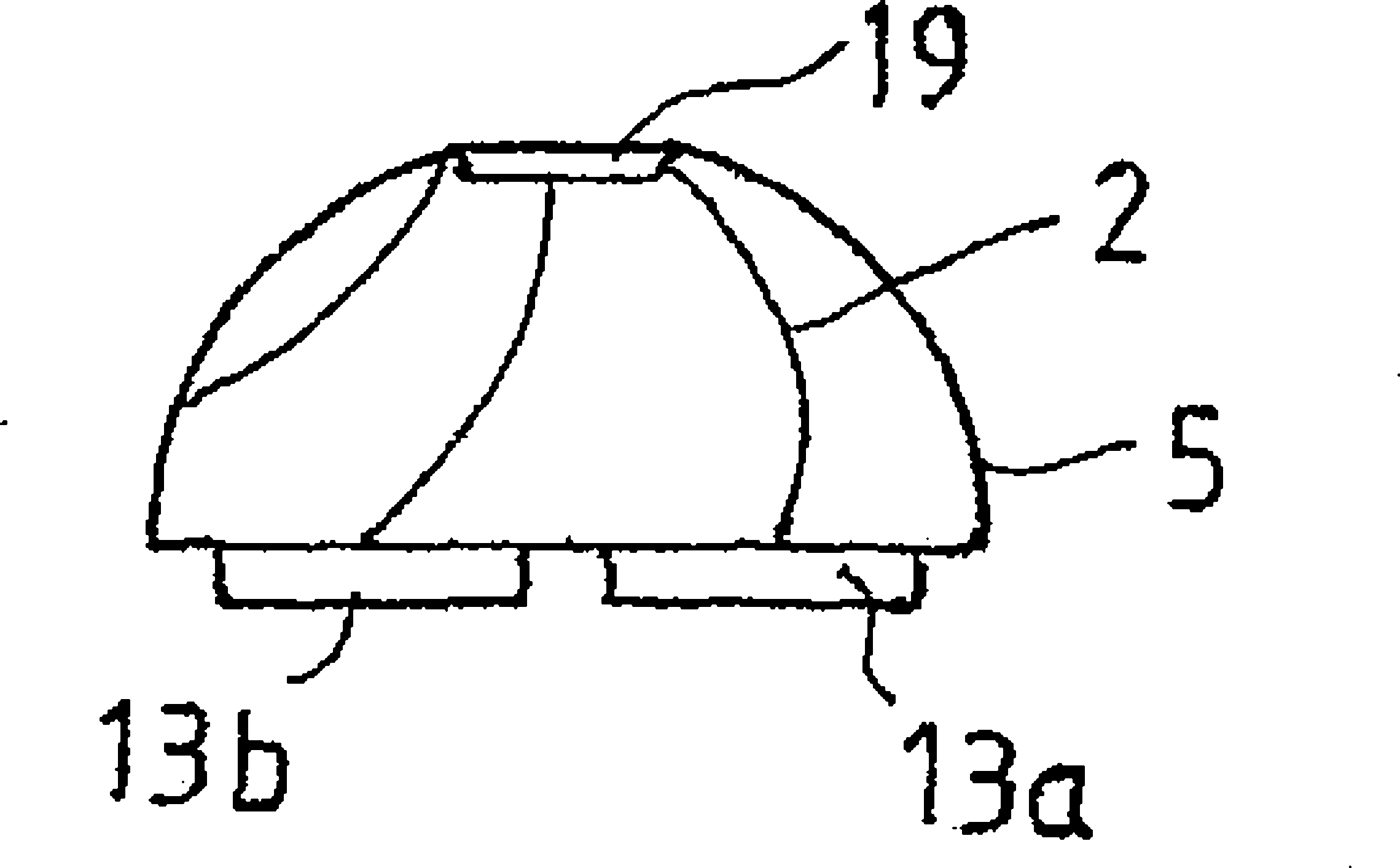

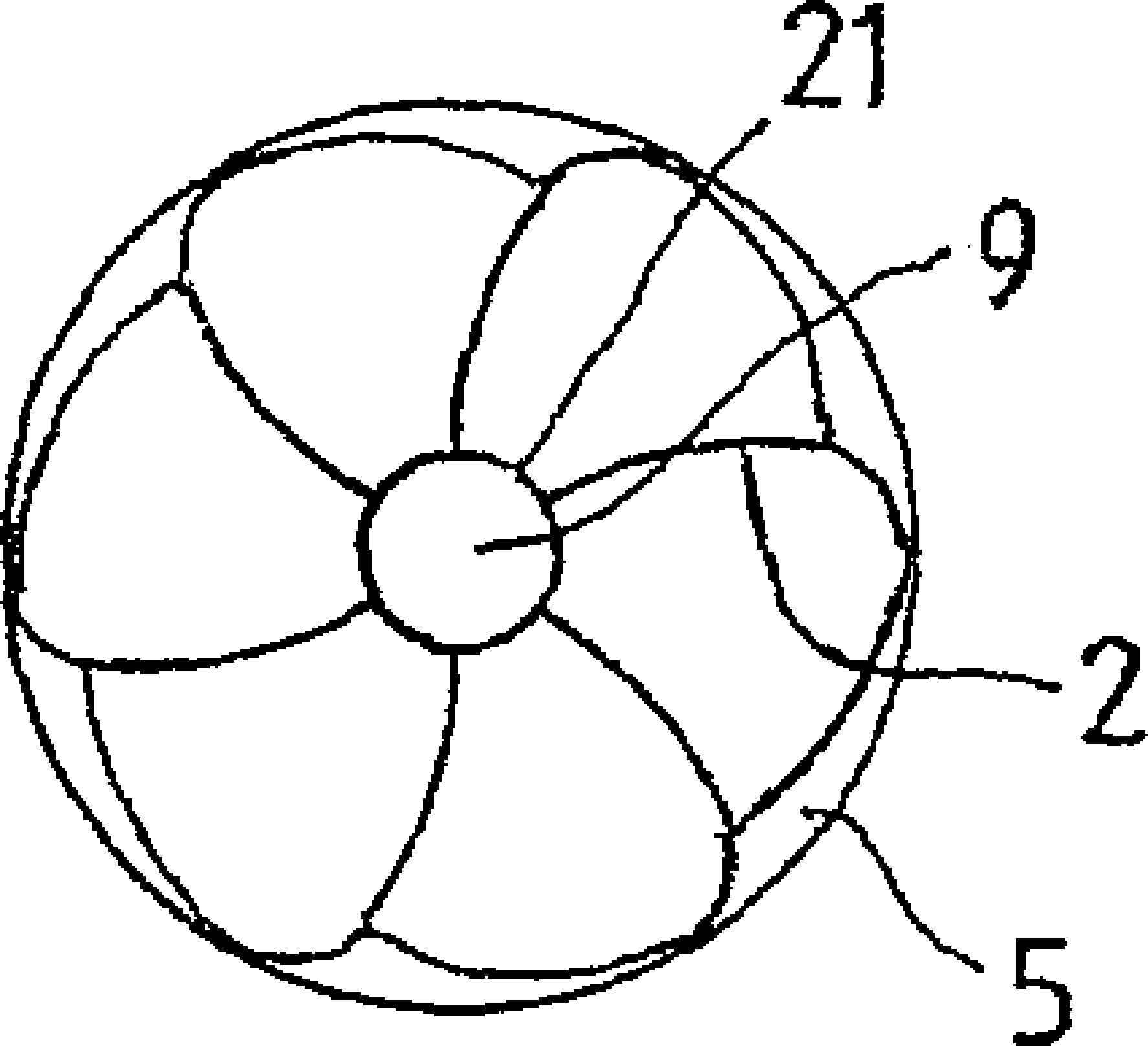

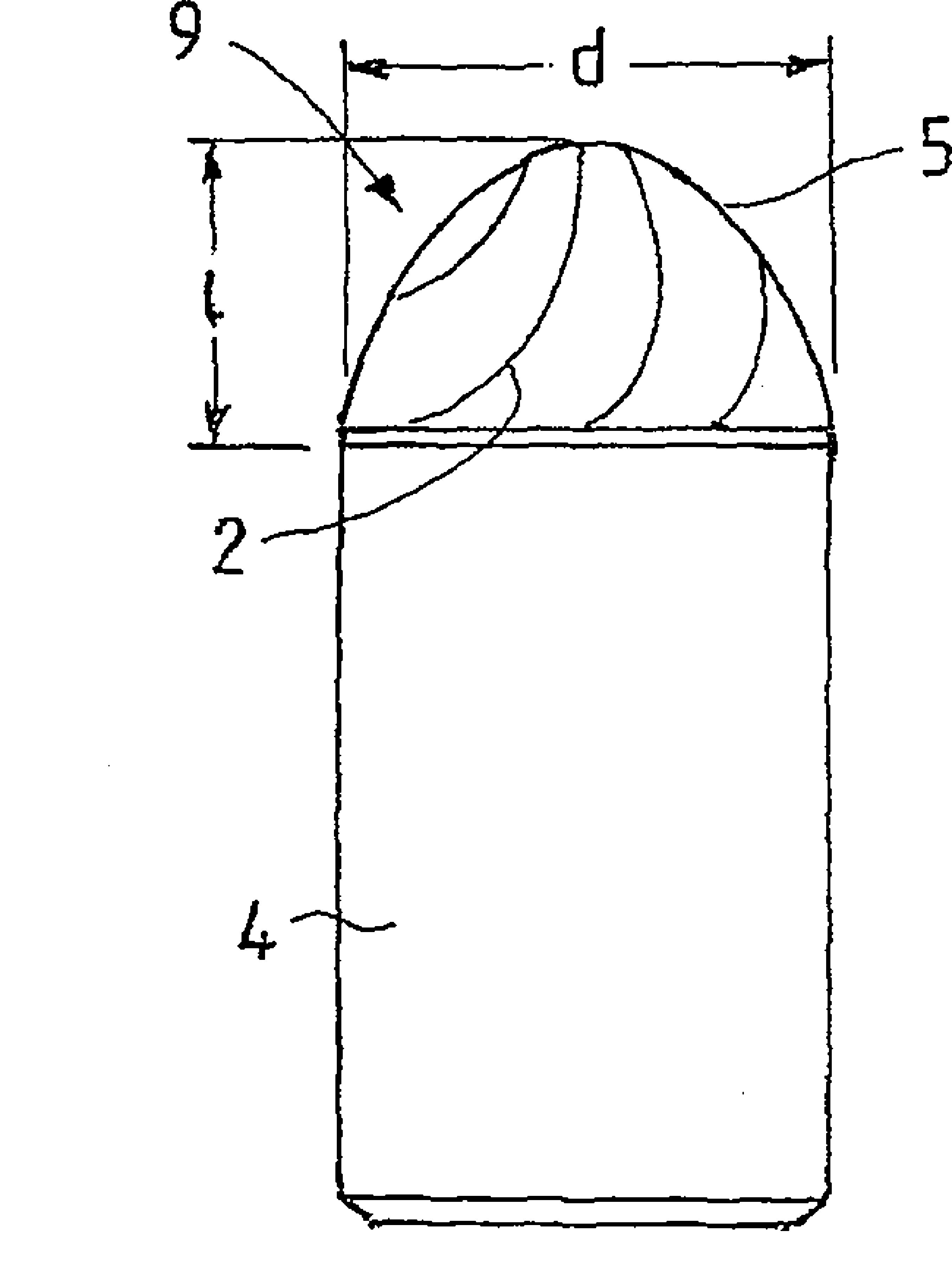

[0033] FIG. 1 shows a longitudinal section of a milling cutter 1 made of a base body 4 and a hemispherical cutting edge part 5 welded to the base body 4 on which the cutting edge 2 is arranged. The milling cutter 1 is mounted for use on a milling machine (not shown). Milling cutter has length l gesamt and diameter d gesamt . The base body 4 and the cutting edge part 5 are formed cylindrically. Base body 4 is made of hard metal or of ceramic.

[0034] The cutting edge part 5 is made entirely of polycrystalline cubic boron nitride (PcBN) or polycrystalline diamond (PKD). The cutting edge part 5 has the same diameter d as the base body 4 gesamt . This diameter is 7mm to 40mm. The cutting edge 2 is formed integrally with the cutting edge member 5 . However, the cutting edge 2 can also be welded to the cutting edge part 5 .

[0035] For form-locking fastening of the cutting edge part 5 on the base body 4, on the bottom side of the cutting edge part 5 facing the base body 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com