A microstructure detection method for freeze-thaw damage of cement-based materials

A cement-based material and microstructure technology, which is used in material analysis using radiation, preparation of test samples, etc., can solve problems such as the inability to monitor the evolution of material microstructure and the difficulty of quantifying monitoring data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

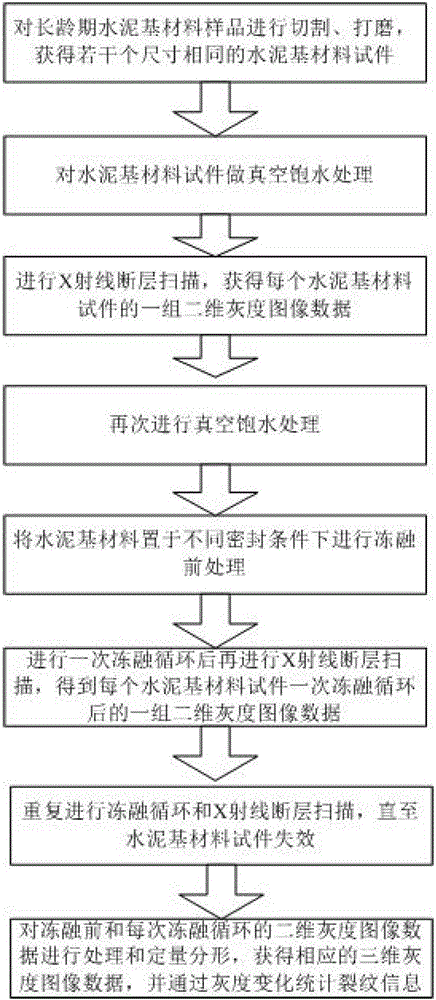

Method used

Image

Examples

Embodiment

[0053] The present embodiment illustrates the method of the present invention with cement slurry. Specific steps are as follows:

[0054] a) Use PI52.5 cement to form a cement slurry sample in a PU pipe with Φ=8.2mm and L=50mm, and put it in a saturated calcium hydroxide solution for curing for 8 months at a curing temperature of T=20±2°C;

[0055] b) Cut and polish the sample into a cylindrical sample with Φ=8.2mm and L=10mm;

[0056] c) adopt vacuum saturated water method, carry out vacuum saturated calcium hydroxide solution treatment to sample;

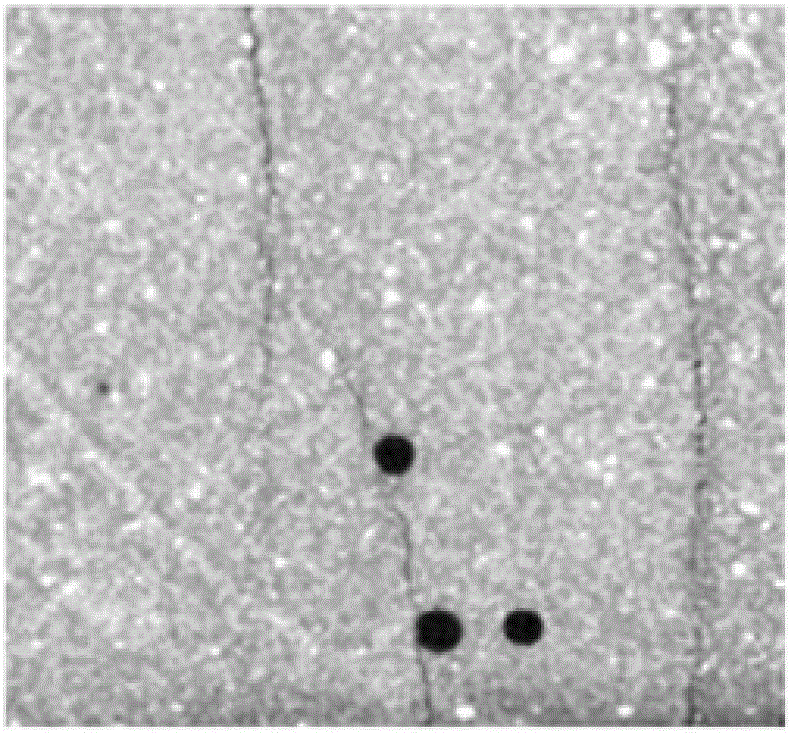

[0057] d) performing X-ray tomography on the sample to obtain a set of initial two-dimensional images IO of the sample before freezing and thawing;

[0058] e) Using the vacuum saturated water method, the sample is again treated with a vacuum saturated calcium hydroxide solution.

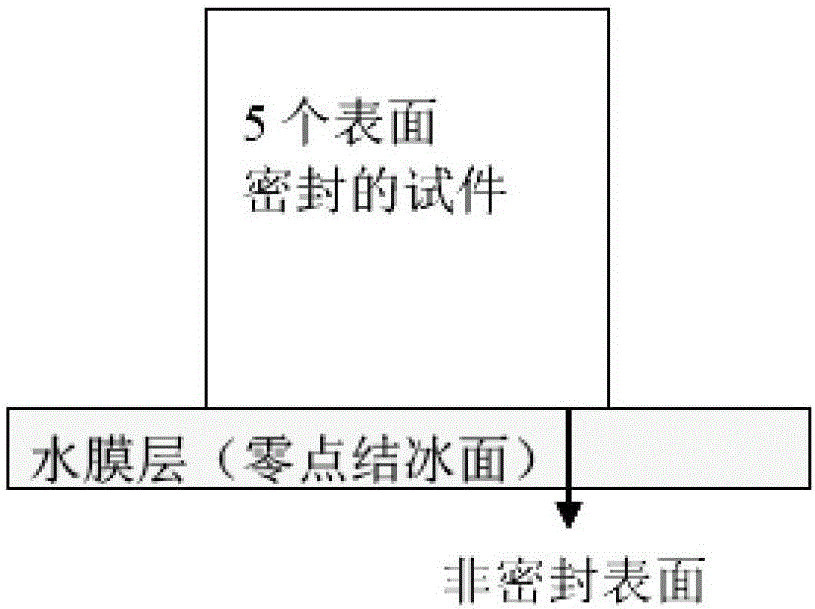

[0059] f) Freezing-thawing pretreatment of samples: immerse a part of the samples in aviation kerosene, coded as sample 1; fully seal a part of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com