Test method for rapidly exposing welding defects of printed circuit board, and test system thereof

A technology for printed circuit boards and soldering defects, applied in electronic circuit testing, measuring devices, thermal analysis of materials, etc., can solve problems such as printed circuit boards not working properly, substrate deformation of electronic components, and easy desoldering, etc., to improve Effects of market competitiveness, improvement of product quality, and improvement of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

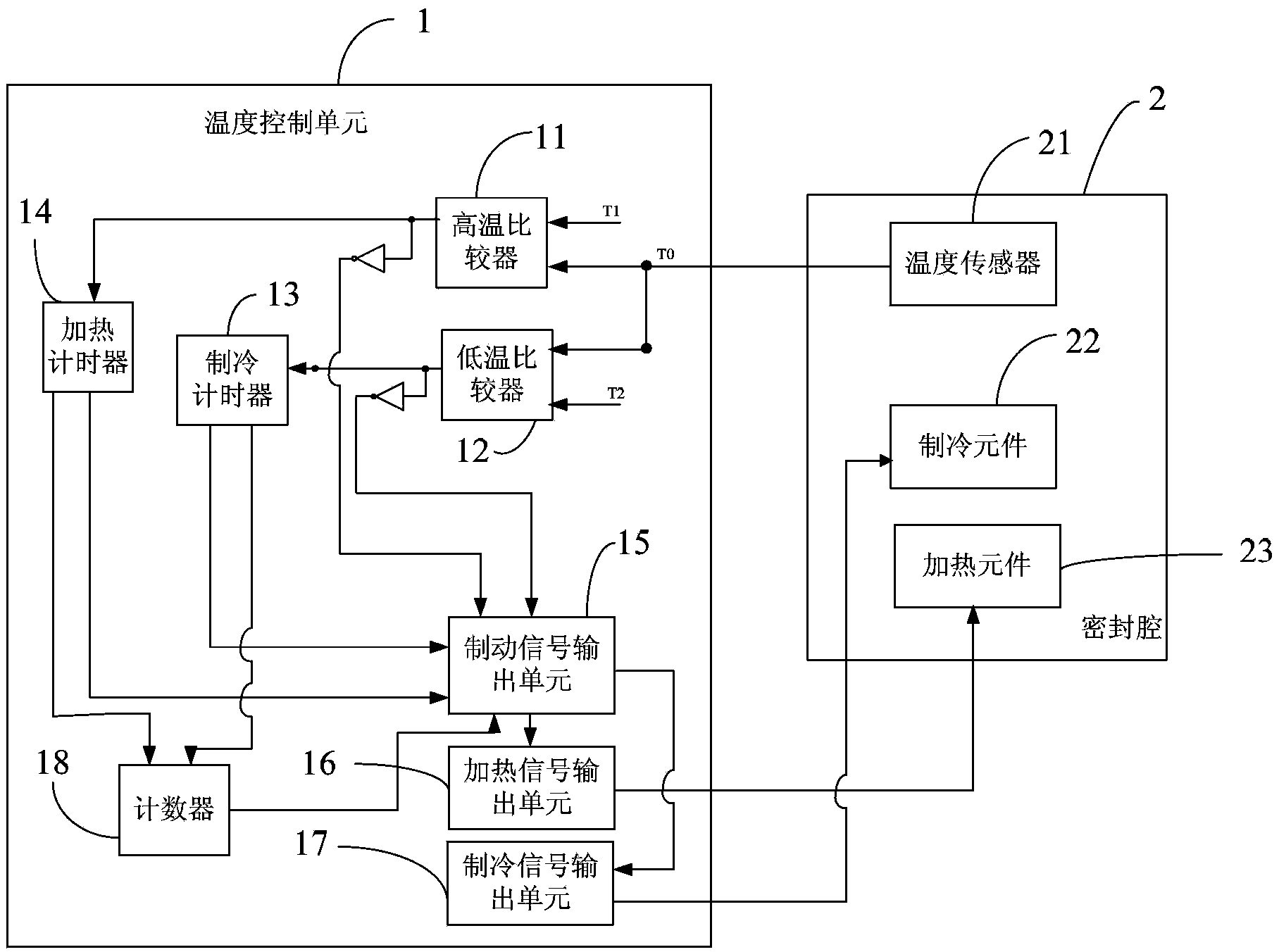

[0017] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0018] The test method for quickly exposing soldering defects of printed circuit boards of the present invention mainly includes the following steps: Step 1: Place the printed circuit board sample in a temperature-controlled environment for temperature stress testing, and make the temperature in the environment pass through the low temperature Alternate cycle with high temperature for several times, and make the low temperature and high temperature in each temperature cycle last for a period of time; Step 2: The printed circuit board sample after the temperature stress test is left at room temperature for a period of time, and then the electrical and mechanical properties are tested. Appearance quality inspection, screening out samples with welding defects.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com