MT (magnetotelluric) denoising device and method

A magnetotelluric and electromagnetic technology, applied in the field of electrical prospecting, can solve problems such as no method to rely on, high human factors, etc., and achieve the effect of improving credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

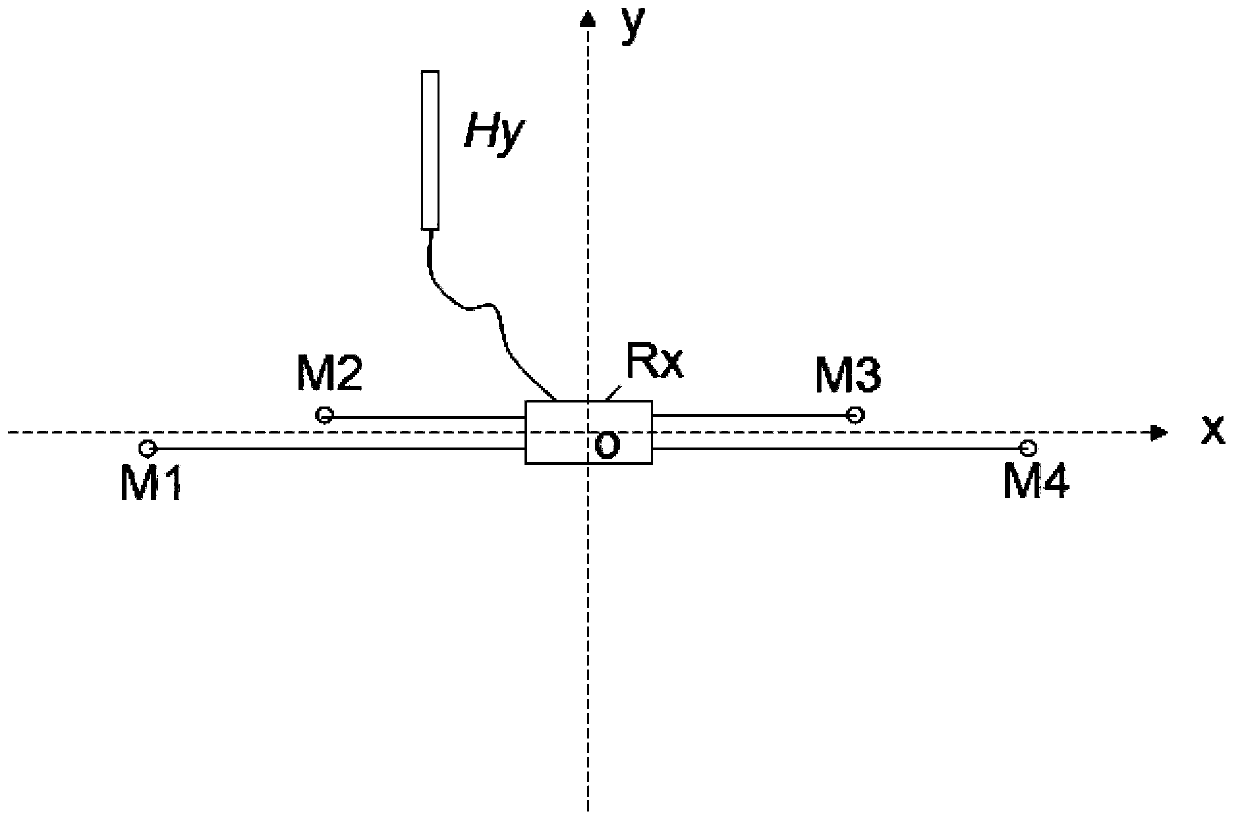

[0051] Such as figure 1 As shown, Embodiment 1 provides a magnetotelluric denoising measurement device, which is a magnetotelluric denoising measurement device based on scalar measurement mode, arranged in the xy coordinate system established with the measurement point as the center point, and can be applied to Natural source magnetotelluric denoising survey or controlled source magnetotelluric denoising survey. Its structure includes:

[0052] An electromagnetic receiver Rx placed on the ground is used to read magnetic field amplitude data and electric field amplitude data;

[0053] A magnetic induction sensor Hy placed on the ground along the direction of the parallel y-coordinate axis, which is connected with the electromagnetic receiver Rx through a cable for measuring magnetic field amplitude data;

[0054] A group of non-polarized electrode groups M1, M2, M3, and M4 are placed symmetrically on the ground along the x-axis with the origin of the coordinate system as the ...

Embodiment 2

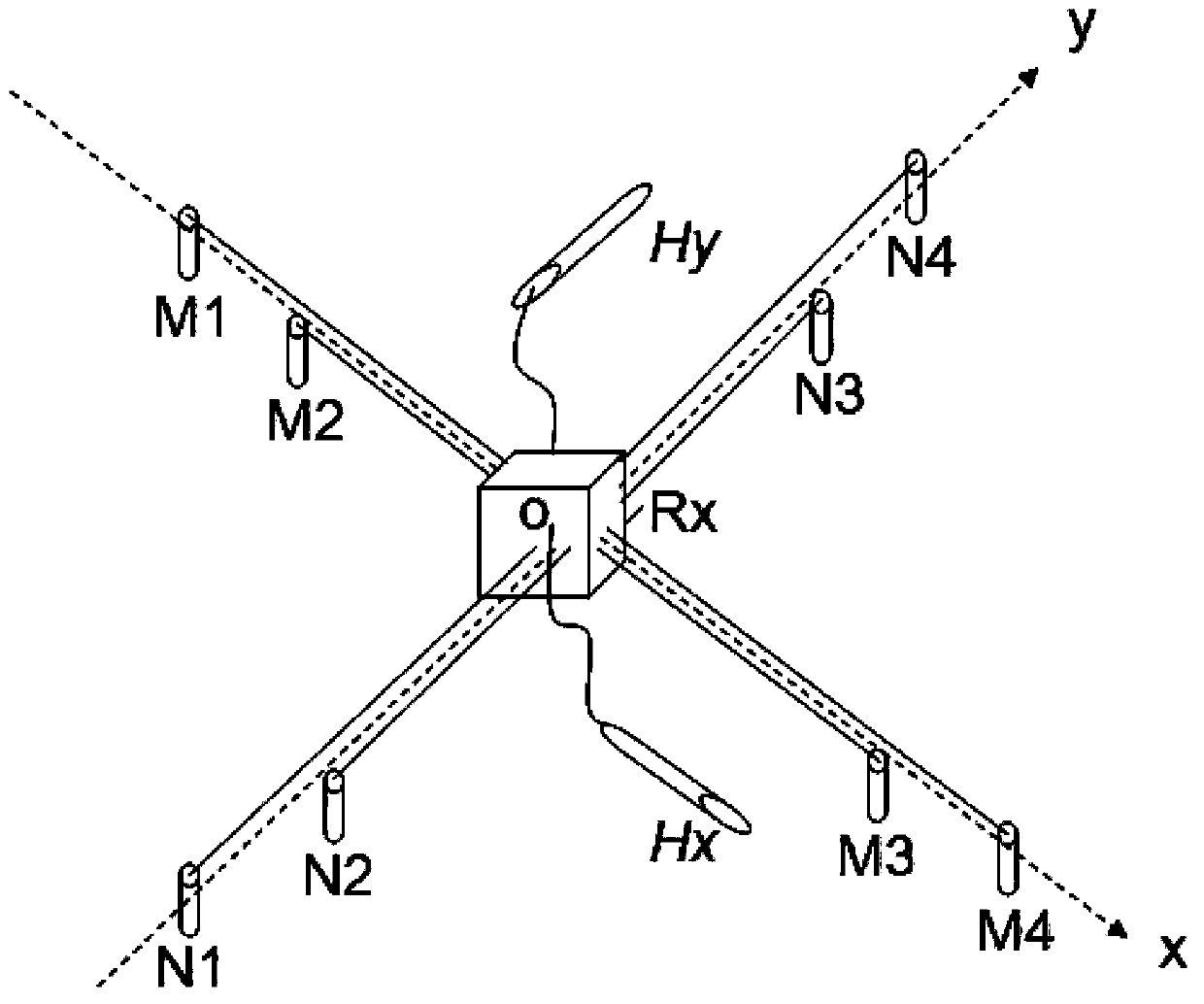

[0063] Such as image 3 As shown, Embodiment 2 provides a magnetotelluric denoising measurement device in vector measurement mode, which is also arranged in the xy coordinate system established with the measurement point as the center point, and can be applied to natural source magnetotelluric denoising measurements or can be Controlled source magnetotelluric denoising measurements. The device in Embodiment 2 is constructed based on the magnetotelluric denoising measurement device used in the scalar measurement mode in Embodiment 1. It only needs to add a set of measurement devices in the scalar measurement mode, and make it rotate 90° with the measurement center o as the axis Spend. The specific structure is:

[0064] An electromagnetic receiver Rx placed on the ground is used to read magnetic field amplitude data and electric field amplitude data;

[0065] A pair of magnetic induction sensors Hx and Hy placed parallel to the ground along the horizontal x and y coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com