A method of increasing the surface area of an inductor

A surface area and inductance technology, applied in the field of increasing the surface area of inductance, can solve the problems of large winding distance and low density, and achieve the effect of improving performance, large winding density, and increasing effective surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

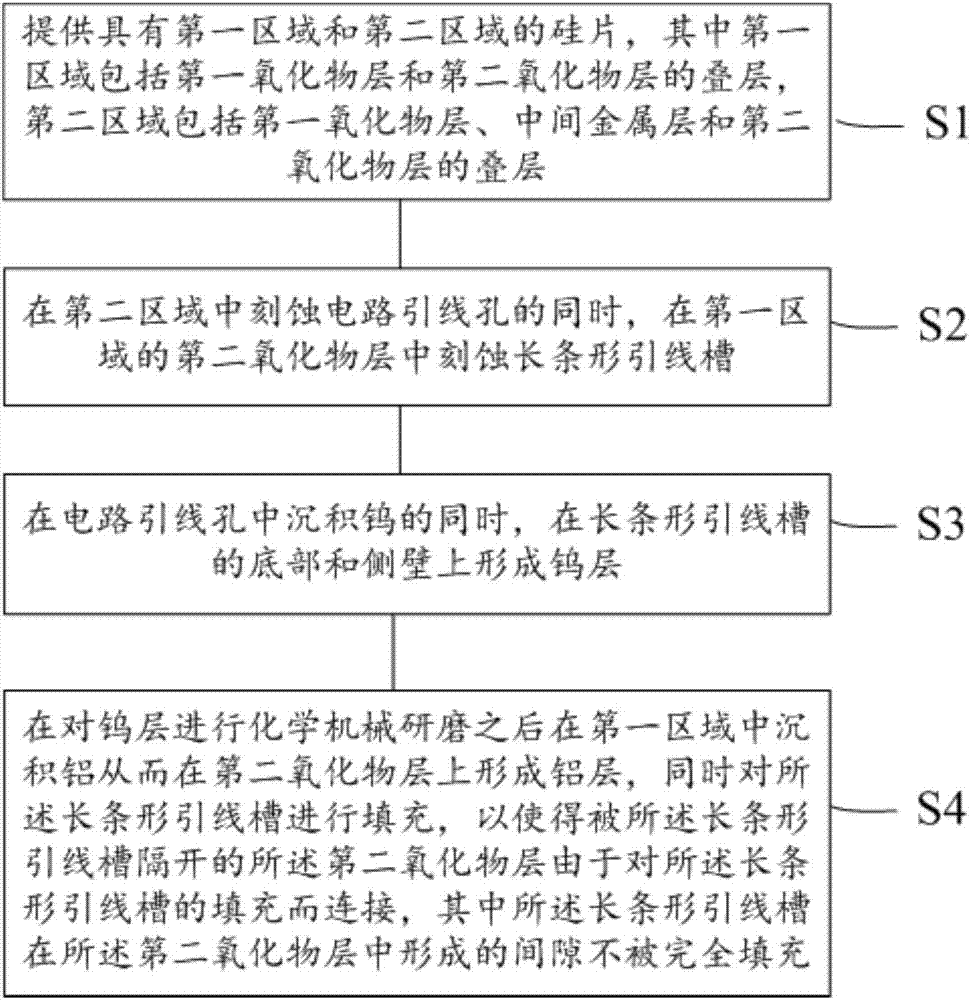

[0022] figure 1 A flow chart of a method for increasing the surface area of an inductor according to an embodiment of the present invention is schematically shown.

[0023] Specifically, as figure 1 As shown, the method for increasing the surface area of an inductor according to an embodiment of the present invention includes:

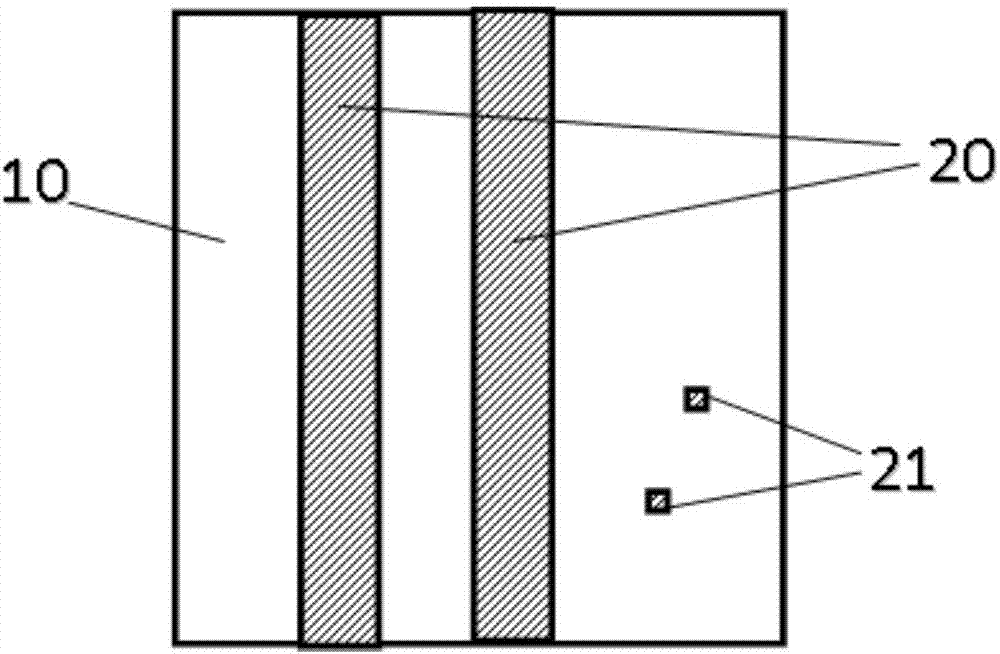

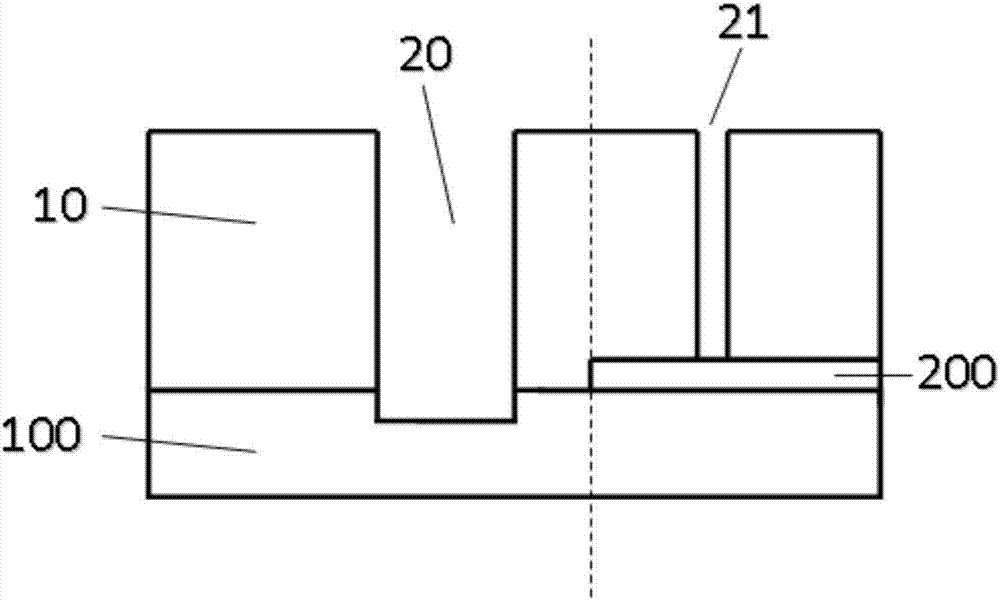

[0024] First step S1: providing a silicon wafer having a first region and a second region, wherein the first region includes a stack of the first oxide layer 100 and the second oxide layer 10, and the second region includes the first oxide layer 100 , the stack of the intermediate metal layer 200 and the second oxide layer 10, such as image 3 As shown in the cross-sectional diagram of , the left side of the dotte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap