Tilting runner apparatus for molten iron

A pouring ditch and molten iron technology, applied in lighting and heating equipment, manufacturing converters, furnace components, etc., can solve problems such as the inability to lift the pouring ditch, and achieve the effect of easy position adjustment and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Next, an embodiment of the molten iron pouring trough facility of the present invention will be described with reference to the drawings.

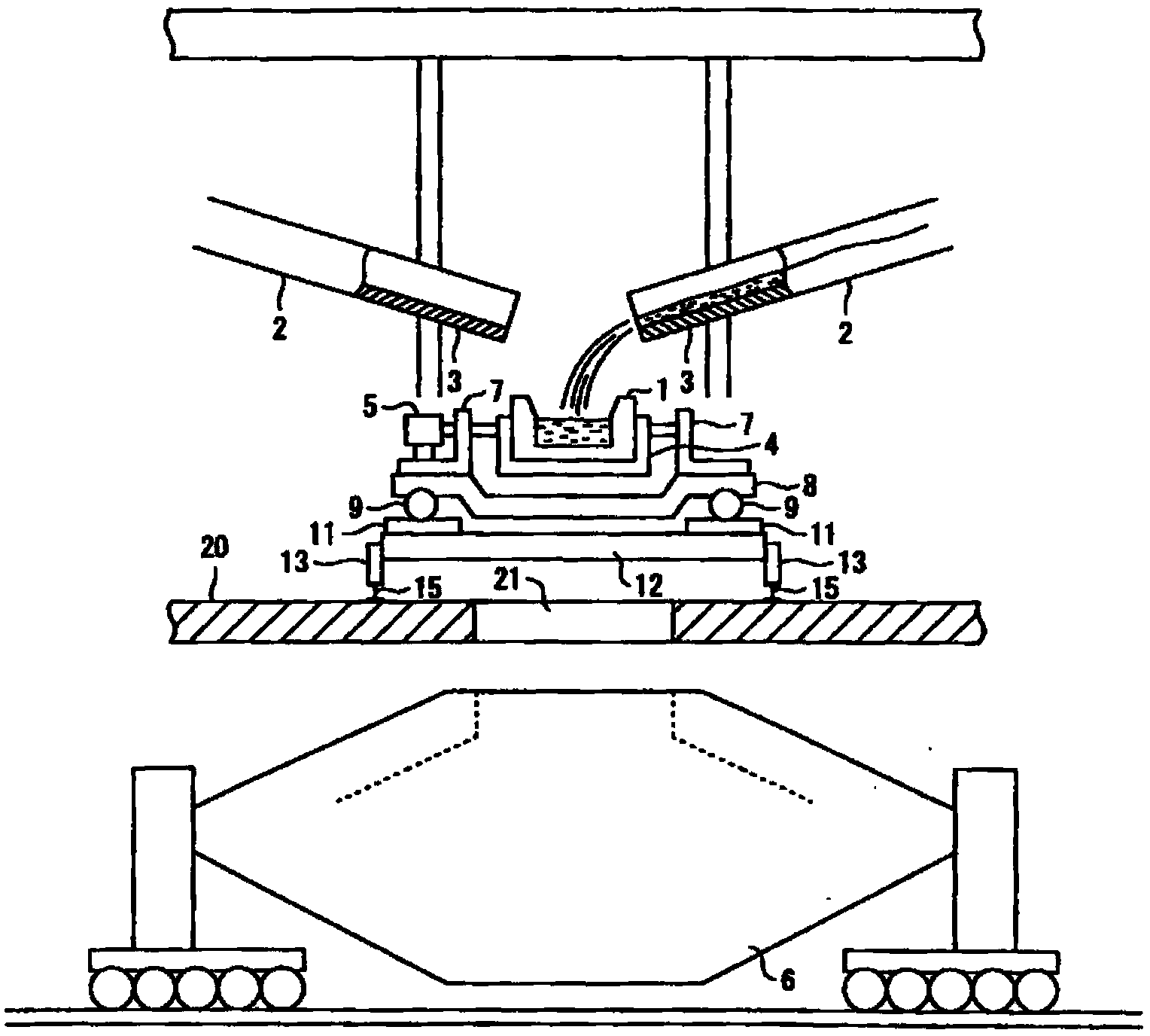

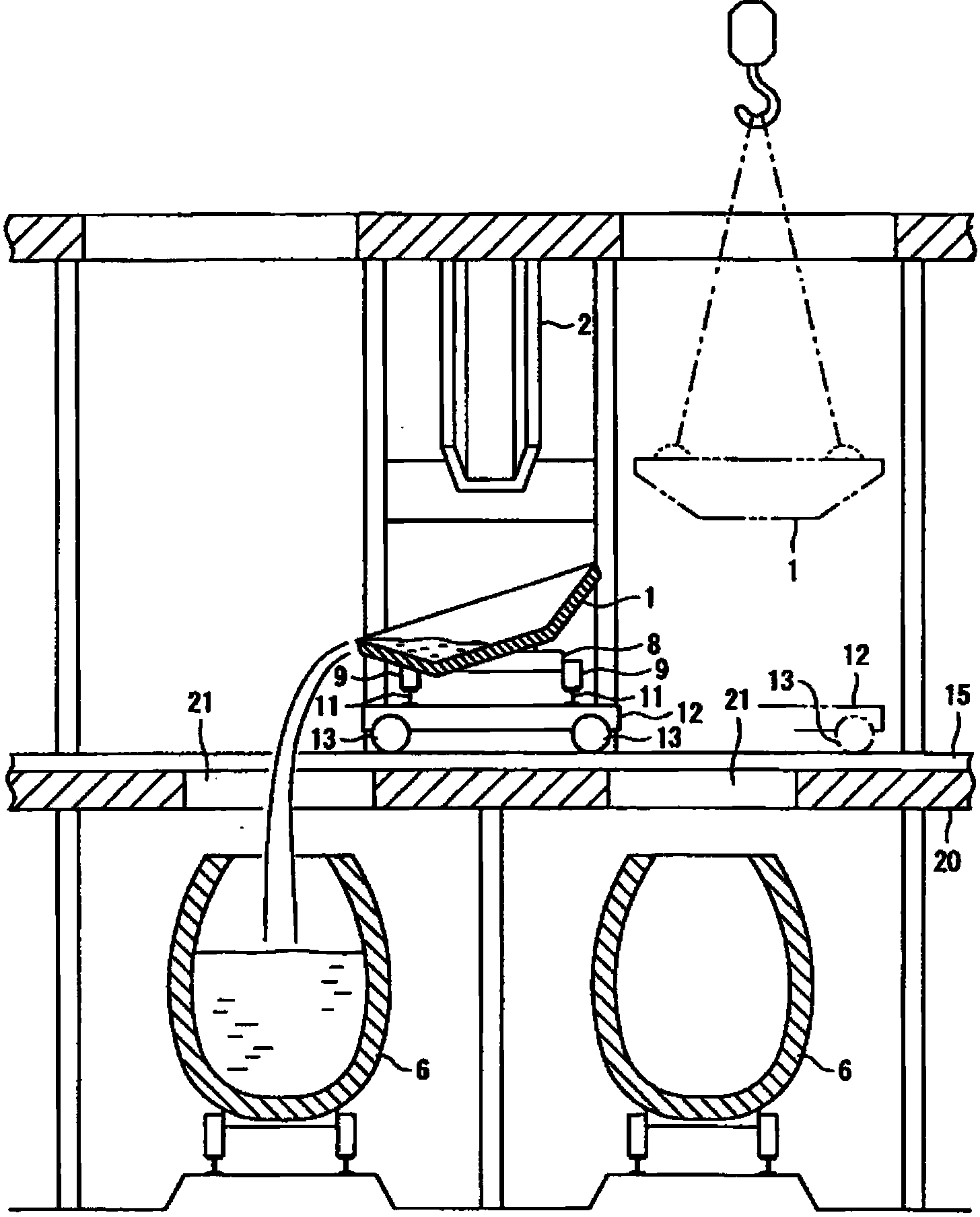

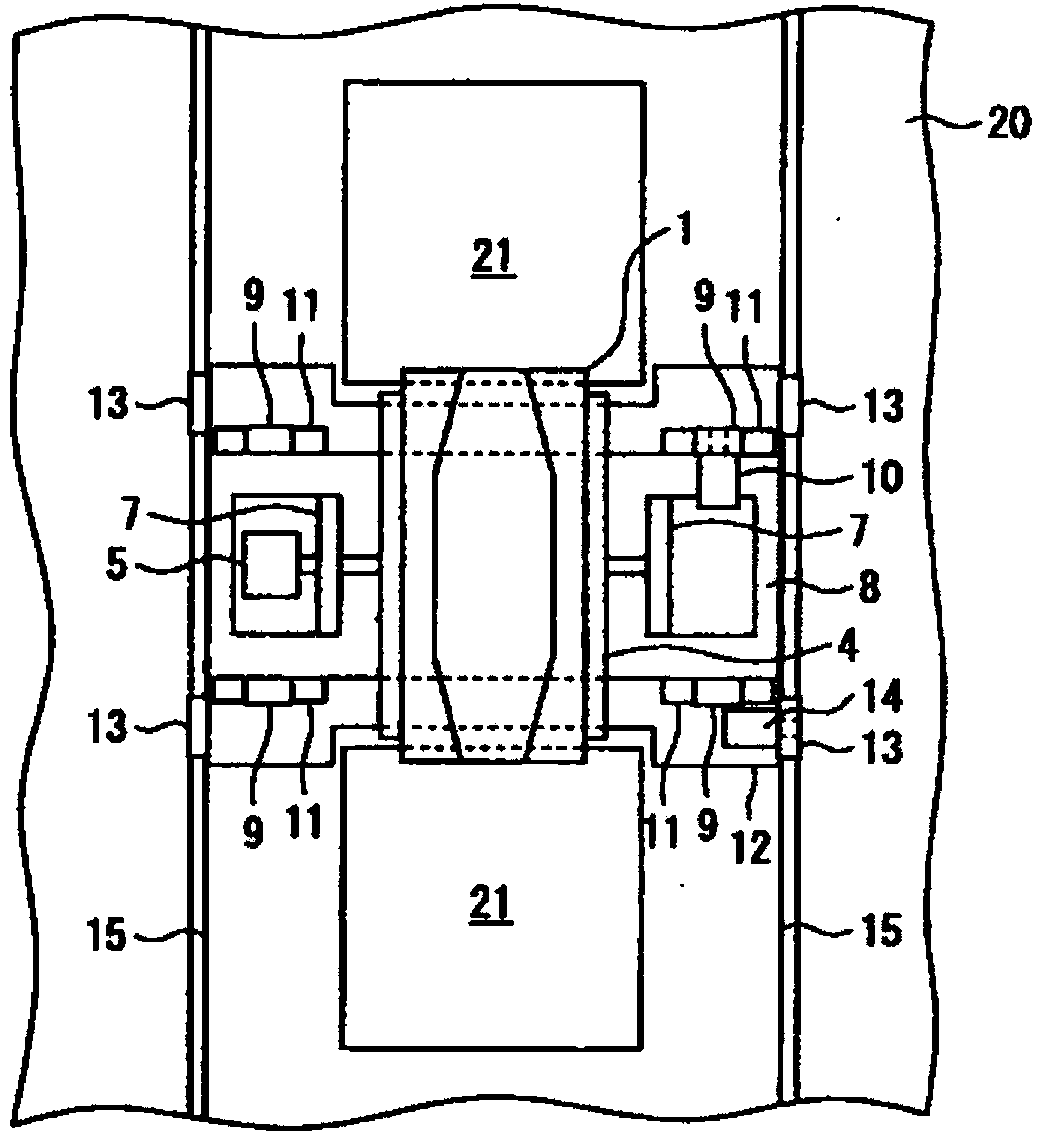

[0023] Figure 1 to Figure 3 It is an overall view of the molten iron pouring trough equipment of this embodiment, figure 1 is the front view, figure 2 is a side view, image 3 is the floor plan. Symbol 1 in the figure is pouring ditch, and symbol 2 is tapping ditch. A metal frame 3 at the end of the iron trough is installed at the lower end of the tap trough 2 . In the figure, the molten iron flowing from the blast furnace is poured from the tapping trough 2 to the pouring trough 1 through the metal frame 3 at the end of the molten iron trough. The pouring channel 1 is supported by a support frame 4 which is rotated by using an electric motor 5, for example figure 2 Tilt in any of the clockwise and counterclockwise directions. Therefore, if figure 2 As shown, by tilting the pouring ditch 1 clockwise or counterclockwise, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com