Absorption tower for producing enriched oxygen through vacuum pressure swing absorption

A technology of vacuum pressure swing adsorption and adsorption tower, which is applied in the chemical industry and can solve the problems of insufficient use of adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

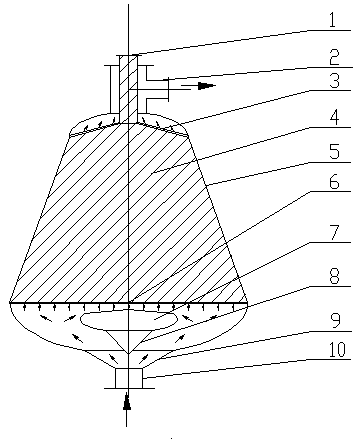

[0033] In this example, the thickness of the adsorbent bed is set to 300 millimeters (mm), the purity of the product gas is designed to be 90%, and the yield is 50%. Keep the gas flow rate in the adsorption tower basically the same, the diameter of the tower bottom is 140mm, then the diameter of the tower top can be calculated as 48.0mm. The included angle at the bottom of the adsorption tower is 81.3°. The effective volume of the adsorbent filled in the adsorption tower is 2240 milliliters (ml).

[0034] use as Figure 4 The shown double-tower VPSA laboratory device uses conical towers and axial towers for comparative experiments. Molecular sieve adsorbents use the same weight. The comparative experimental conditions are shown in the table below:

[0035]

[0036] VPSA device timing table:

[0037]

[0038] VPSA installation and electromagnetic program-controlled valve switch table:

[0039]

[0040] In the table: A: Adsorption; ED1: Equalizing and depressurizi...

Embodiment 2

[0047] In this embodiment, the calculation method of the included angle of the conical tower is as follows: firstly, the thickness of the adsorbent bed is set to 300mm, the purity of the product gas is designed to be 75%, and the yield is 60%. Keep the gas flow rate in the adsorption tower basically the same, and the diameter at the bottom of the tower is 140 mm, then the diameter at the top of the tower can be calculated as 57.0 mm. The included angle at the bottom of the adsorption tower is 82.1°. The effective volume of the adsorbent filled in the adsorption tower is 2430 ml.

[0048] Using the same method as in Example 1, only the oxygen concentration was controlled at about 75%, and the oxygen production conditions of the conical tower and the axial tower VPSA were compared.

[0049]

[0050]

[0051] The experimental results of axial tower and conical tower are shown in the table below:

[0052]

[0053] From the experimental results, it can be seen that the oxy...

Embodiment 3

[0056] In this embodiment, the calculation method of the included angle of the conical tower is as follows: firstly, the thickness of the adsorbent bed is set to 300mm, the purity of the product gas is designed to be 70%, and the yield is 65%. Keep the gas flow rate in the adsorption tower basically the same, the diameter of the bottom of the tower is 140 mm, then the diameter of the top of the tower can be calculated as 67.0 mm. The included angle at the bottom of the adsorption tower is 83.1°. The effective volume of the adsorbent filled in the adsorption tower is 2620 ml.

[0057] Using the same method as in Example 1, only the oxygen concentration was controlled at about 60%, and the oxygen production conditions of the conical tower and the axial tower VPSA were compared.

[0058]

[0059] The experimental results of axial tower and conical tower are shown in the table below:

[0060]

[0061] From the experimental results, it can be seen that the oxygen production o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com