Three-dimensional fluorocarbon simulation mineral varnish aluminum veneer manufacturing technology and aluminum veneer thereof

A manufacturing process, a technology of simulating stone, applied in building structures, devices for coating liquids on surfaces, special surfaces, etc., can solve problems such as unfavorable ecological environment, vegetation and soil damage, water and soil loss, etc., and achieve a wide range of applications, Rich three-dimensional effect, strong concave and convex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The manufacture of the real stone paint and the real stone metal plate of the present invention will be further described below in conjunction with the accompanying drawings and examples.

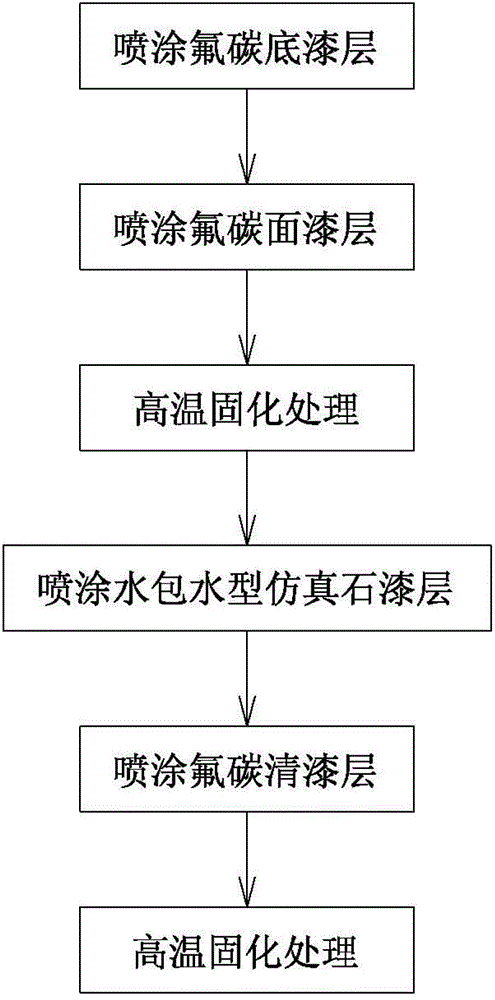

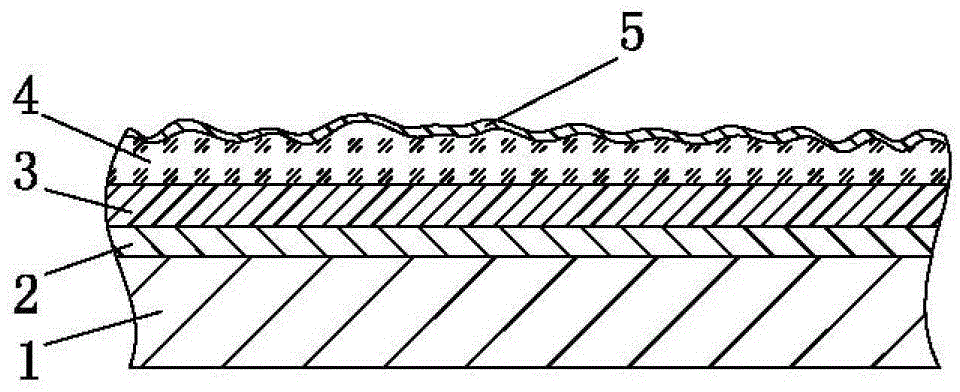

[0032] First, according to the real stone samples or holographic pictures, analyze the color background and color distribution in the three-dimensional real stone, as the color selection of the aluminum veneer fluorocarbon topcoat and the color distribution model of the water-in-water type artificial stone paint, its color distribution model Including the approximate proportion of red dots, black dots or other color dots in the real stone, the size and shape of the dots, including the three-dimensional levels of layer by layer color. According to the above analysis, the spraying process is compiled, taking imitation granite as an example, the spraying process is as follows (such as figure 1 ):

[0033] First prepare the aluminum substrate, spray fluorocarbon primer on the aluminum s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com