Adjustable positioning device for open punching of press

A positioning device and press technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as ineffective punching of rough blanks, eccentric waste products, folding waste products, etc. , to achieve the effects of reducing mold investment and adjustment, improving production efficiency, and facilitating production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

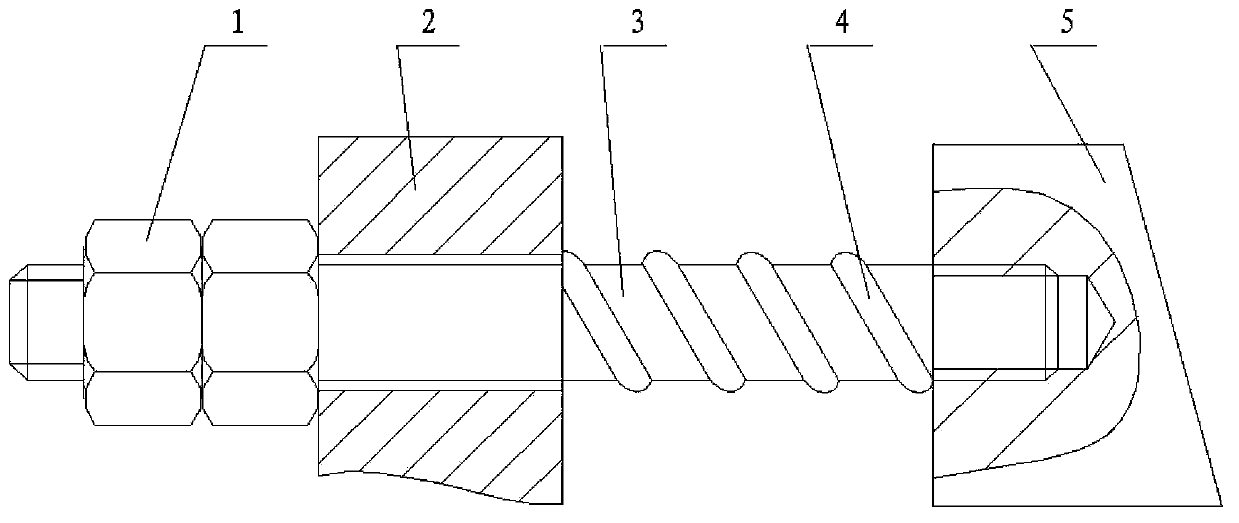

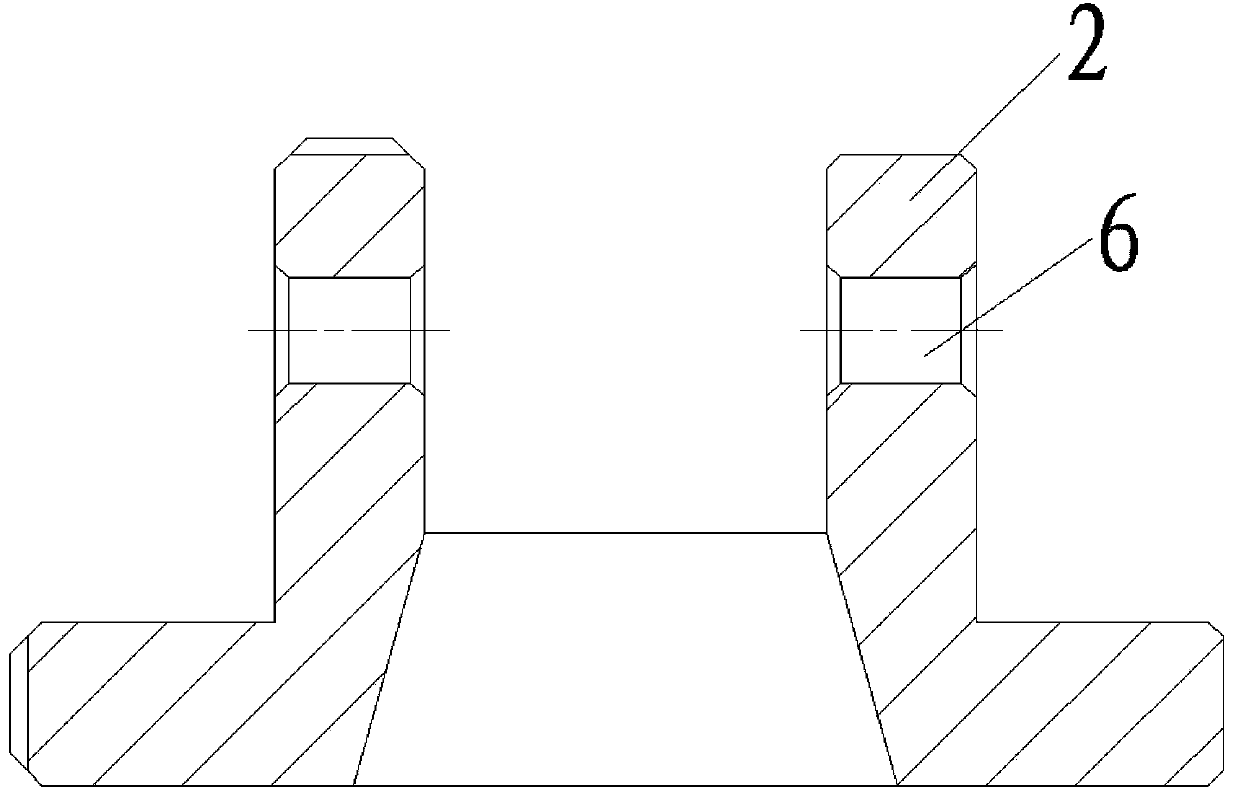

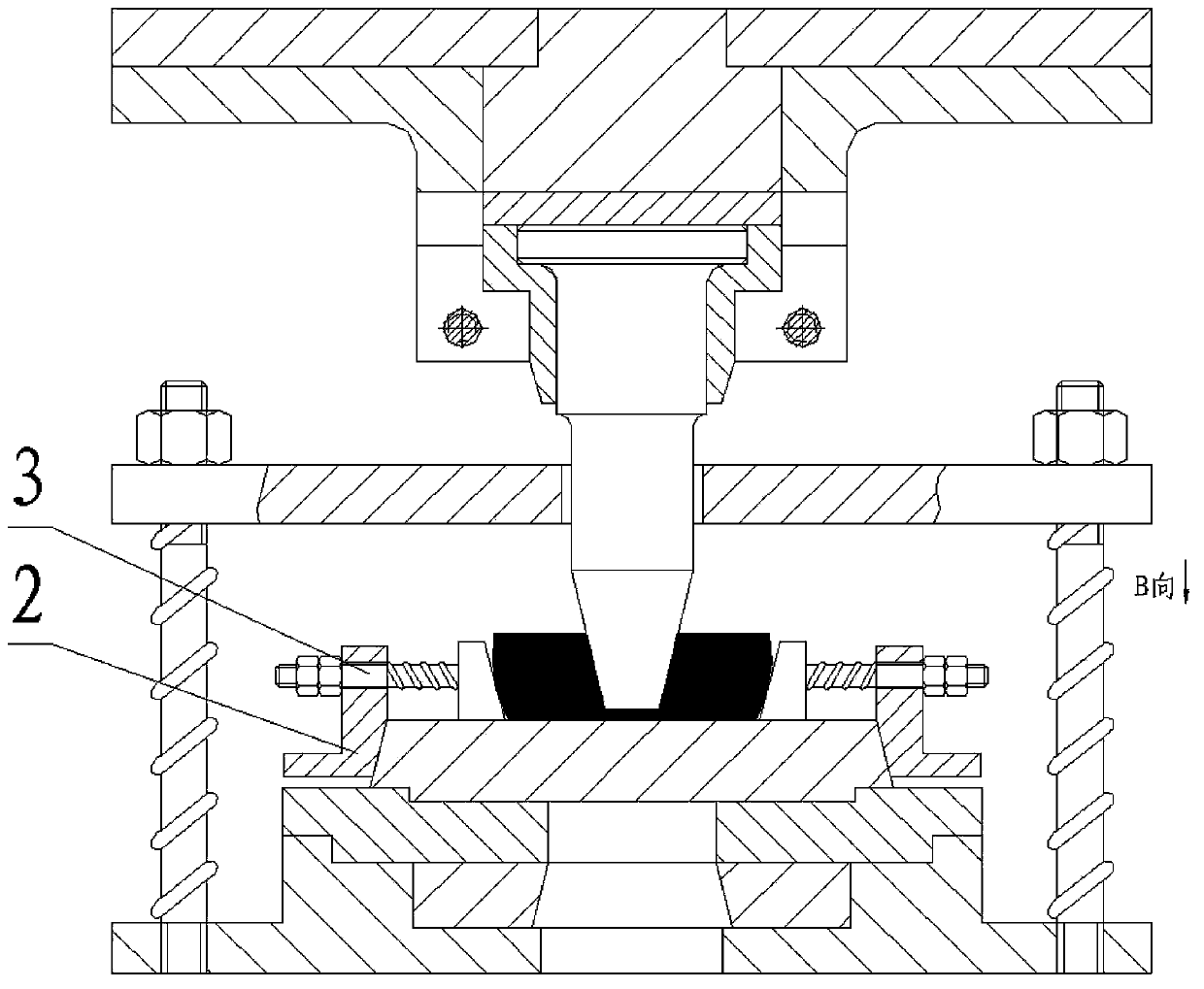

[0015] Such as figure 1 , 2 , 3, and 4, the present invention is an adjustable positioning device for open-type punching of a press, comprising a gland 2, a through hole is opened in the middle of the gland 2, and the outer wall of the gland 2 along the circumferential direction There are 3-6 installation holes 6 evenly distributed, such as Figure 4 3 are shown in . A telescopic positioning rod (referred to as positioning rod) is installed on each mounting hole 6, and the two ends of the telescopic positioning rod respectively protrude from the inside and outside of the outer wall of the gland 2 so as to clamp the forging to be processed in the middle.

[0016] Wherein the telescopic positioning rod includes a pull rod 3, which is inserted into the mounting hole 6, and a chuck 1 is installed on the pull rod 3 outside the outer wall of the gland 2, and a clamp is installed at the end of the same pull rod 3 inside the outer wall of the gland 2. A positioning head 5, and a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com