Preparation method of beaded nanowire toughened and reinforced ceramic coat

A nanowire toughening and ceramic coating technology is applied in the field of preparation of bead string nanowire toughening and reinforced ceramic coatings, which can solve the limitation of nanowire toughening and strengthening, and the anti-oxidation ability of C/C composite materials is not ideal. , the coating is easy to crack, etc., to achieve the effect of reducing the cracking trend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

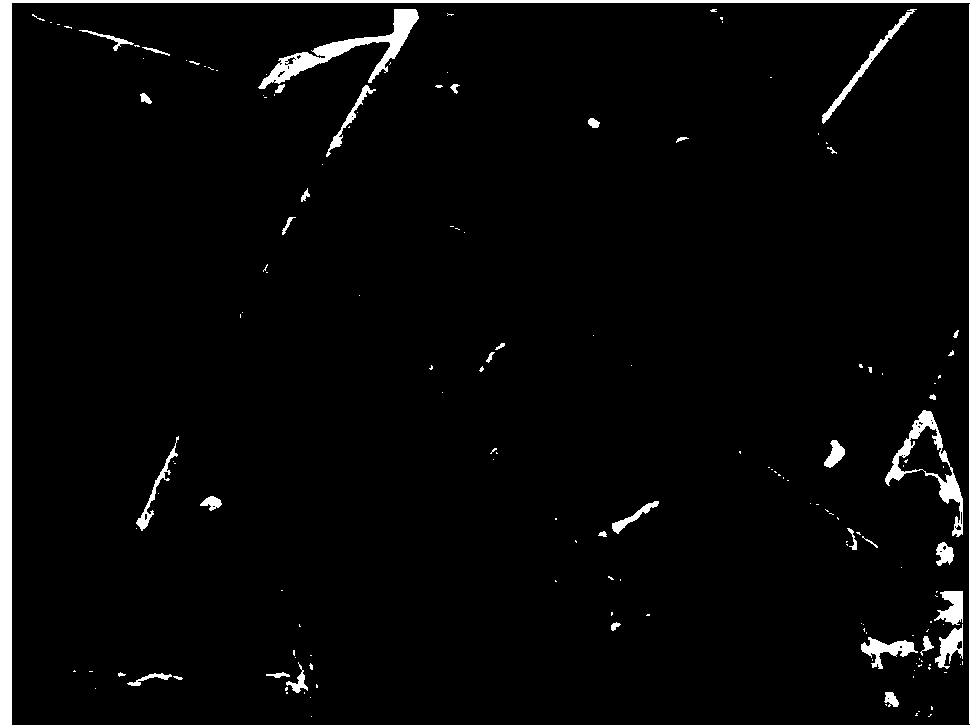

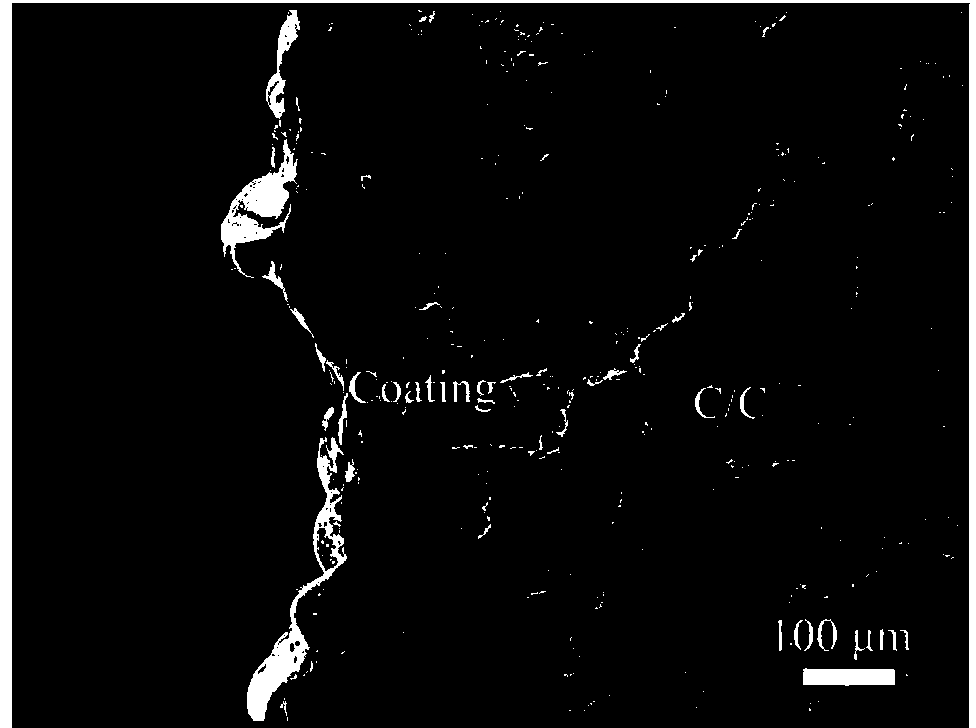

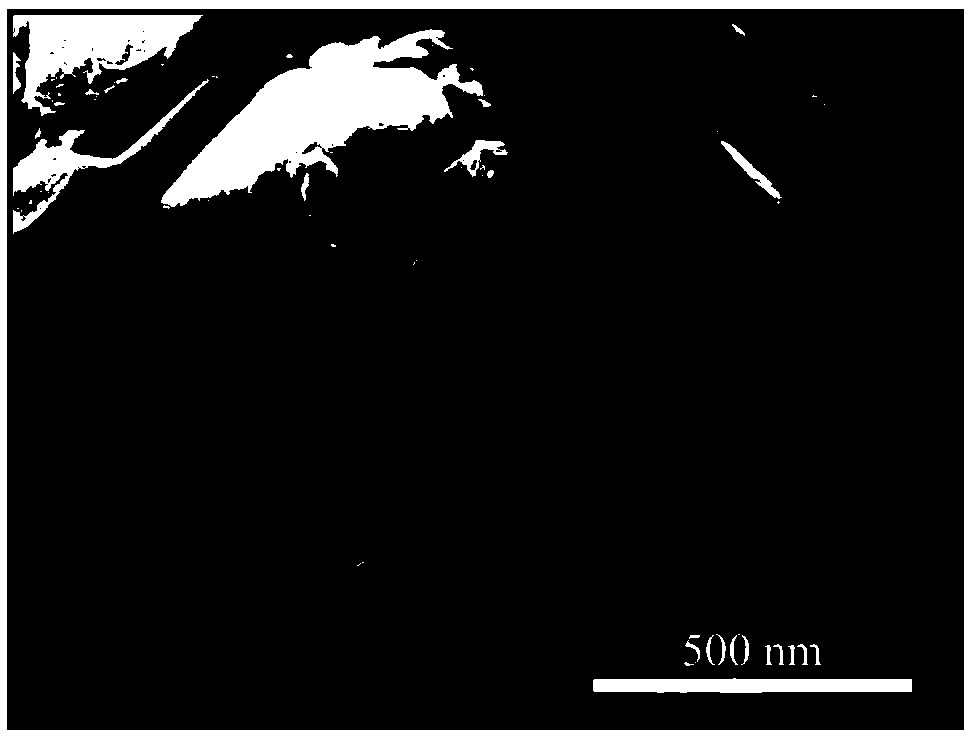

Image

Examples

Embodiment 1

[0032] The C / C composite material was polished and polished sequentially with No. 400, No. 800 and No. 1000 sandpaper respectively, washed with absolute ethanol, and dried in an oven for later use.

[0033] Weigh 60g of Si powder, 15g of SiC powder, 15g of C powder, 10g of Al 2 o 3 pink. Place in a ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 2 hours to obtain embedding powder.

[0034] Put the above 1 / 2 embedding powder into the graphite crucible, put the prepared C / C composite material, and then put the above 1 / 2 embedding powder, so that the powder evenly covers the C / C composite material, then put the graphite crucible into the high-temperature reaction sintering furnace, then raise the furnace temperature to 2200°C, the heating rate is 10°C / min, then keep it warm for 1h, then turn off the power and naturally cool to room temperature, and pass Ar in the...

Embodiment 2

[0040] The C / C composite material was polished and polished sequentially with No. 400, No. 800 and No. 1000 sandpaper respectively, washed with absolute ethanol, and dried in an oven for later use.

[0041] Weigh 72g of Si powder, 10g of SiC powder, 11g of C powder and 7g of Al 2 o 3 pink. Place in a ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 3 hours to obtain embedding powder.

[0042] Put the above 1 / 2 embedding powder into the graphite crucible, put the prepared C / C composite material, and then put the above 1 / 2 embedding powder, so that the powder evenly covers the C / C composite material, then put the graphite crucible into the high-temperature reaction sintering furnace, then raise the furnace temperature to 2100°C, the heating rate is 7°C / min, then keep it warm for 2h, then turn off the power and naturally cool to room temperature, and pass Ar in th...

Embodiment 3

[0048] The C / C composite material was polished and polished sequentially with No. 400, No. 800 and No. 1000 sandpaper respectively, washed with absolute ethanol, and dried in an oven for later use.

[0049] Weigh 85g of Si powder, 5g of SiC powder, 7g of C powder, 3g of Al 2 o 3 pink. Place in a ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 4 hours to obtain embedding powder.

[0050] Put the above 1 / 2 embedding powder into the graphite crucible, put the prepared C / C composite material, and then put the above 1 / 2 embedding powder, so that the powder evenly covers the C / C composite material, then put the graphite crucible into the high-temperature reaction sintering furnace, then raise the furnace temperature to 2000°C, the heating rate is 5°C / min, then keep it warm for 3h, then turn off the power and naturally cool to room temperature, and pass Ar in the who...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com