Streamlined main girder structure

A streamlined, main girder technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as poor aerodynamic performance, ability to ensure driving safety cannot meet the needs of use, etc., to achieve reliable driving safety, large vertical and horizontal bending resistance And torsional modulus, the effect of improving driving conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

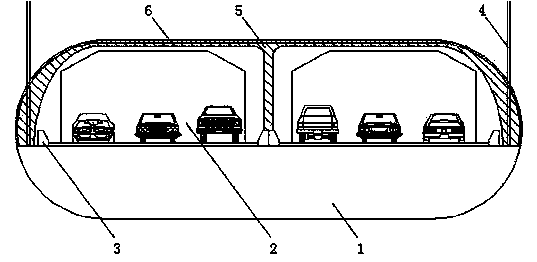

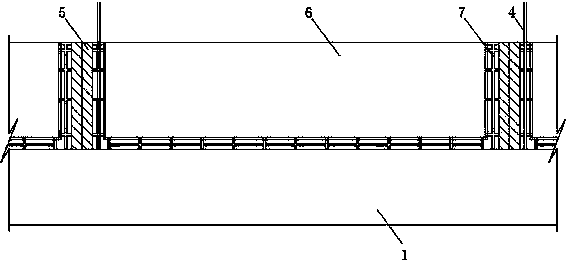

[0023] Example reference figure 1 , figure 2 As shown, a highway suspension bridge adopts a ship-shaped steel box girder 1 as the load-bearing main girder, and the upper cover mainly includes the air guide cover of the bracket 5, the membrane body 5 and the clamp system 7, and the sides of the steel box girder 1 and the air guide cover Smooth butt joint, the cross-sectional outline of the formed streamlined main girder is a round end shape, the main body of the crosswind of the bridge flows around the round end shape, and a small part is guided from the air through the small structural gaps on the edge of the air guide cover membrane inside the hood.

[0024] The air shroud is composed of several membrane structural units arranged and connected longitudinally along the bridge, such as figure 2 As shown, the membrane structural unit includes a support 5 , a membrane body 6 and a clamp system 7 . Ship-shaped steel box girder 1 is elastically supported by sling 4 , and sling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com