Gas pressure chamber with protection function

A gas pressure and protection function technology, applied in fluid pressure actuating devices, fluid pressure actuating system testing, pressure vessels, etc. The effect of improving the explosion-proof level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

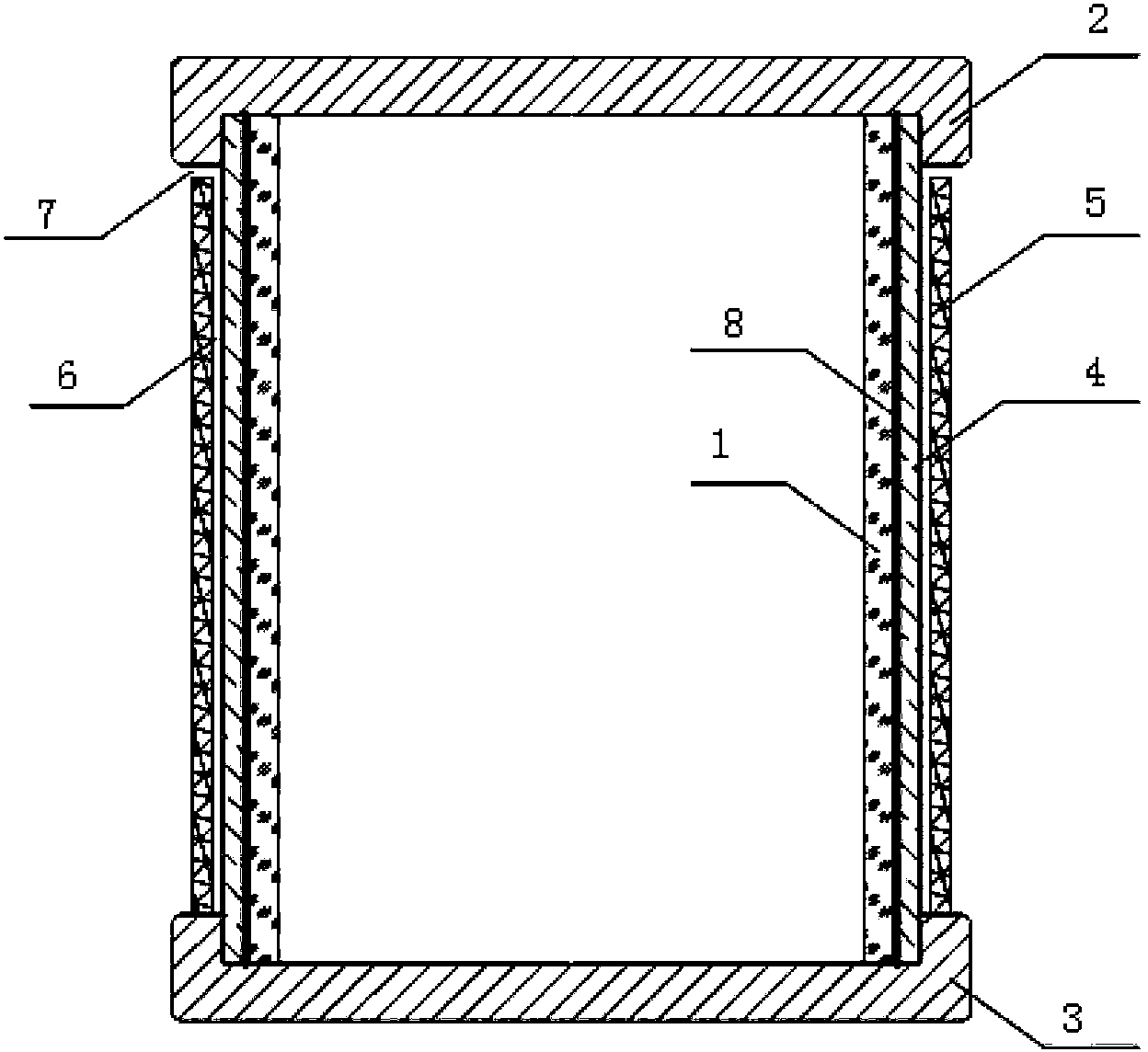

[0022] figure 1 It is a structural schematic diagram of the gas pressure chamber with protection function of the present invention. As shown in the figure, the gas pressure chamber with protective function disclosed by the present invention is applied in the oil liquid sampling system of the automatic oil particle counter, which includes a cylinder body 1, an upper sealing cover 2 and a lower sealing cover 3, and the The body 1 is covered with a metal protection layer 4, and the upper sealing cover 2 and the lower sealing cover 3 seal and cover the cylinder body 1 and the metal protection layer 4, and an outer sheath 5 is arranged outside the metal protection layer 4, and the metal protection layer 4 There is a buffer gap 6 between the outer sheath 5 and a pressure relief slit 7 between the outer sheath 5 and the upper sealing cover 2 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com