Waterproof projection lamp

A technology for floodlights and lamp housings, applied in the field of lighting, can solve problems such as unreliable waterproof sealing performance, potential safety hazards, affecting electrical circuits, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

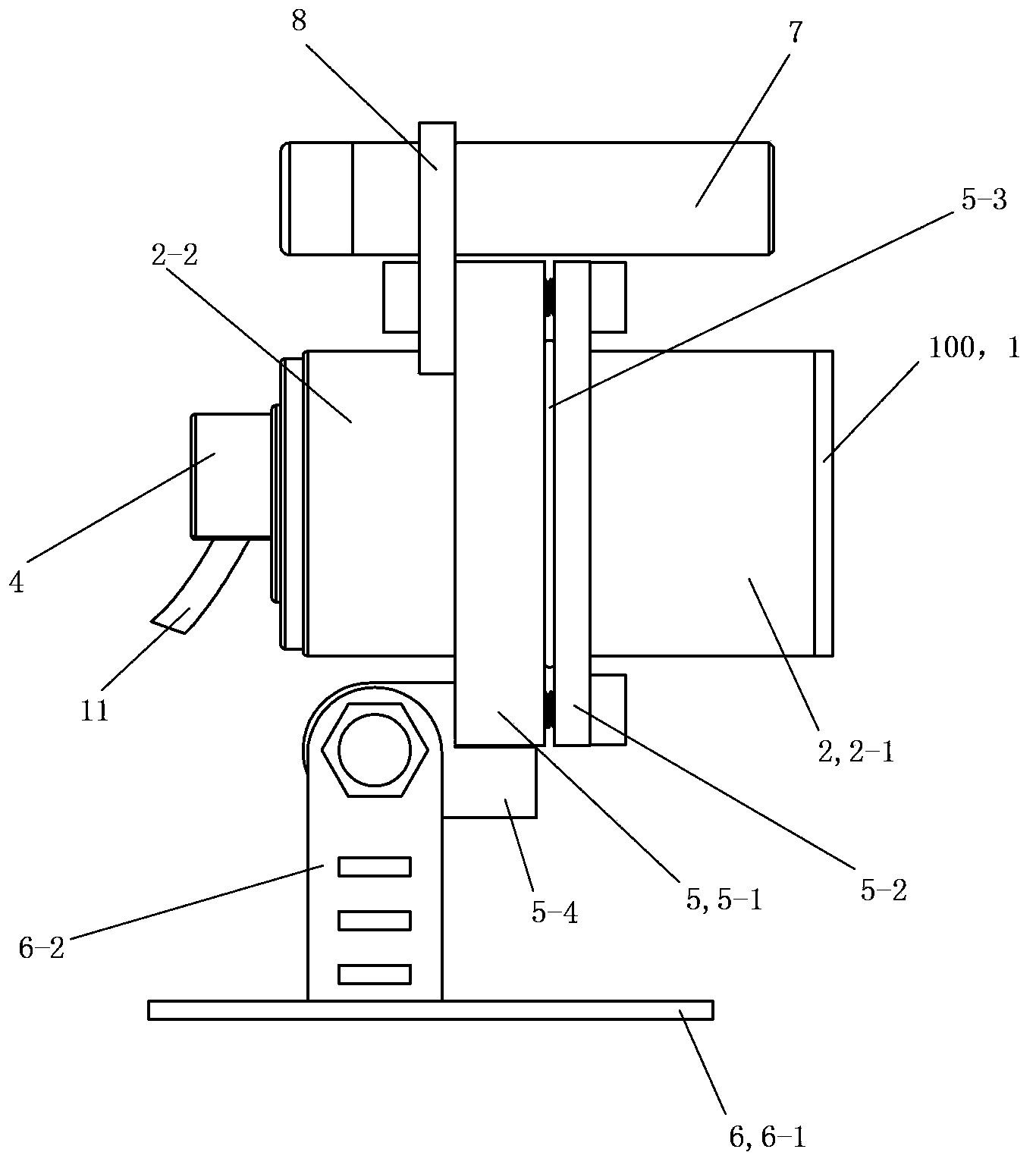

[0043] See figure 1 with Image 6 , The waterproof floodlight of the present invention includes a lamp body 100 , a connecting assembly 5 , a bracket 6 , a laser emitter 7 and a connecting frame 8 .

[0044] See figure 1 with Image 6 , the lamp body 100 includes a lampshade 1 , a lamp housing 2 , a wiring cap 4 , an LED lamp board 9 , a lens assembly 10 and a power cord 11 .

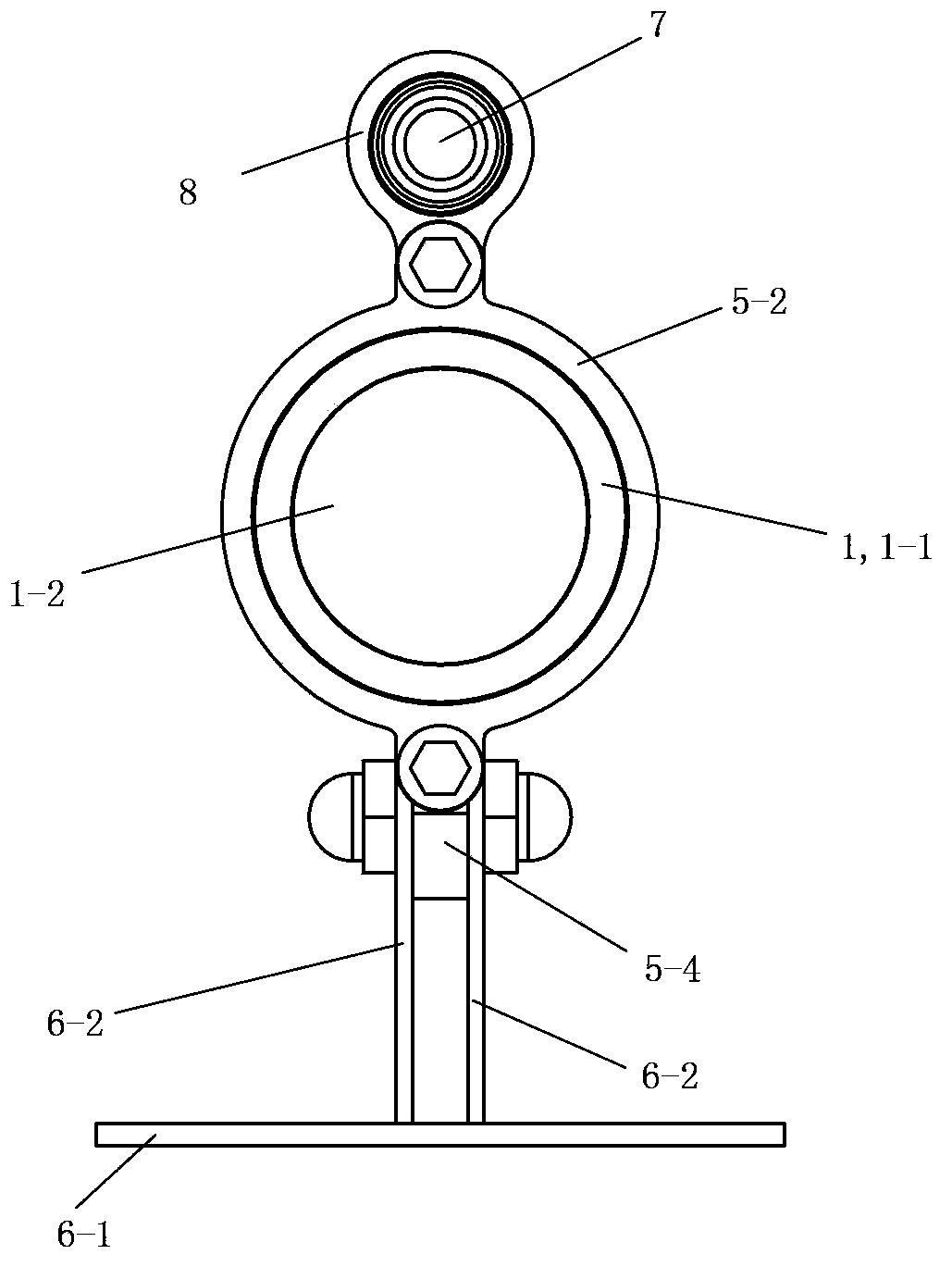

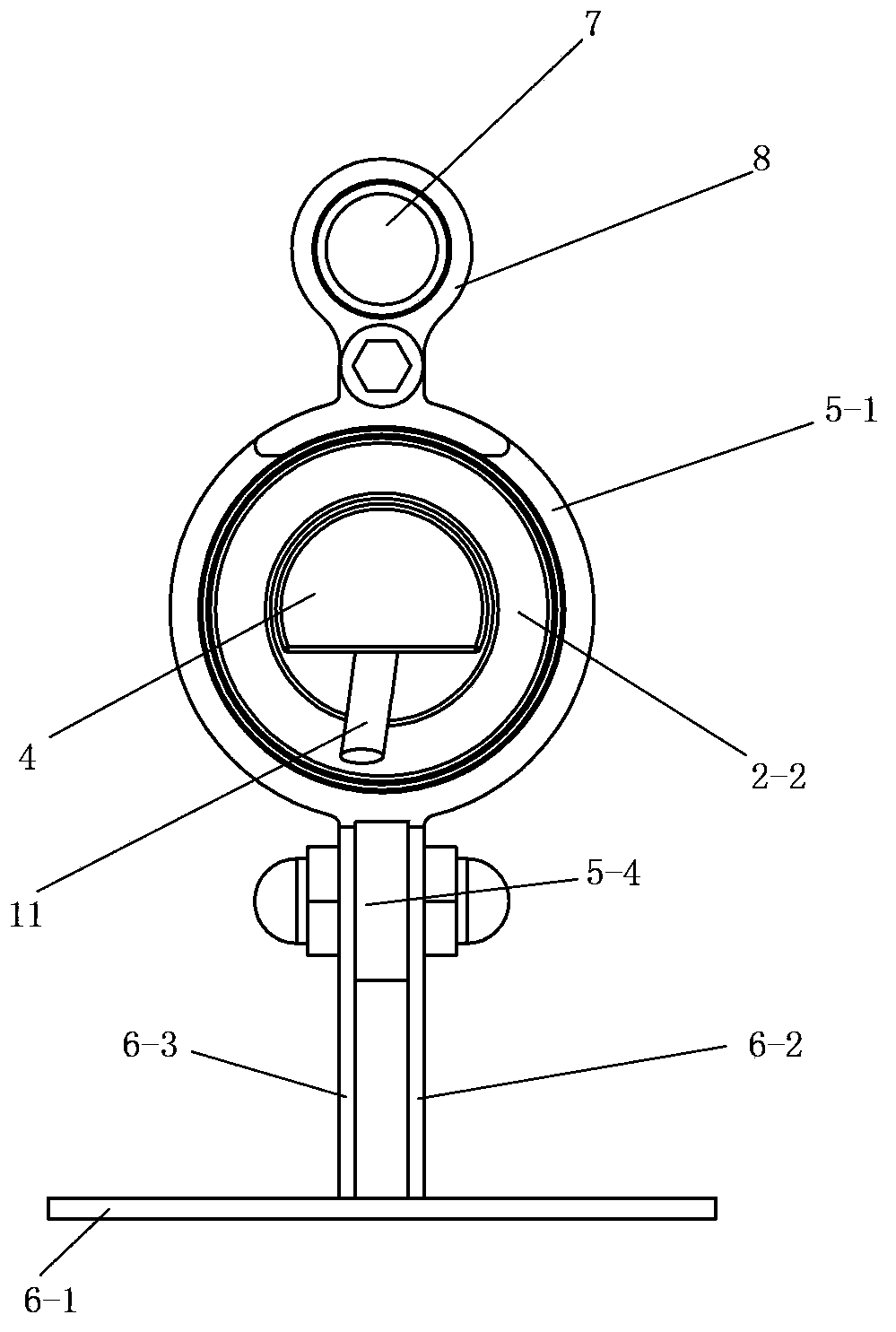

[0045] See figure 2 , Figure 5 with Image 6 , The lampshade 1 includes a stainless steel flange 1-1 and a glass 1-2 made of stainless steel. The stainless steel flange 1-1 of this embodiment adopts 316 stainless steel. The glass 1-2 is airtight and fixedly arranged in the stainless steel flange 1-1. When making, first process the glass into the shape and size corresponding to the stainless steel flange, then put it into the stainless steel flange, and place it in the corresponding graphite mold together, and then enter the electric furnace oven for heating, using nitrogen gas Protection, at ...

Embodiment 2)

[0057] See Figure 9 with Figure 10 , the rest of this embodiment is the same as that of Embodiment 1, except that the connection assembly 5 includes a first connection ring 5-1 and an adjustment plate 5-4.

[0058] The stainless steel sealing plate 4-1 of the wiring cap 4 is provided with a circular through hole 4-1-1. The glue filling part 4-2 is a cylindrical shell-shaped part with an opening facing to the right made of stainless steel, and its shape corresponds to the circular through hole 4-1-1. The left side of the glue filling part 4-2 is provided with a wire hole 4-2-1 running through it. The glue potting part 4-2 is laser welded from left to right, sealed and fixedly connected to the circular through hole 4-1-1 of the stainless steel sealing plate 4-1.

[0059] The first connecting ring 5-1 is an integral piece made of steel, and the upper part of the outer circumference of the first connecting ring 5-1 is provided with a radially outward protruding part, and the ...

Embodiment 3)

[0062] This embodiment is the same as Embodiment 1, and the difference is that the lamp housing 2 of this embodiment is one piece, without the front lamp housing 2-1, and the left and right length of the original rear lamp housing 2-2 is extended It is the sum of the left and right lengths of the original front lamp housing 2-1 and the rear lamp housing 2-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com