Domestic stove

A household furnace and furnace body technology, which is applied in the direction of household furnace/stove, efficiency improvement of household appliances, lighting and heating equipment, etc., can solve problems such as high smoke concentration, troublesome use of household furnaces, pollution, etc., to reduce smoke concentration and improve combustion Efficiency and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

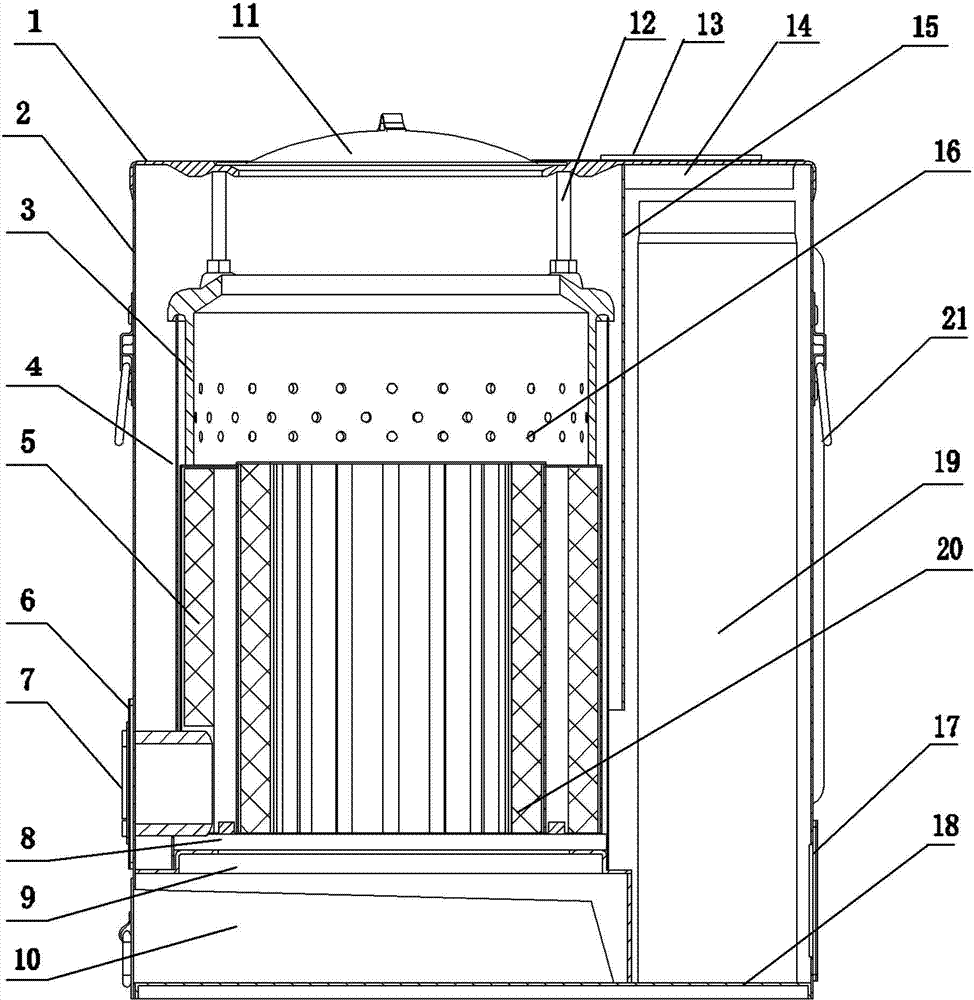

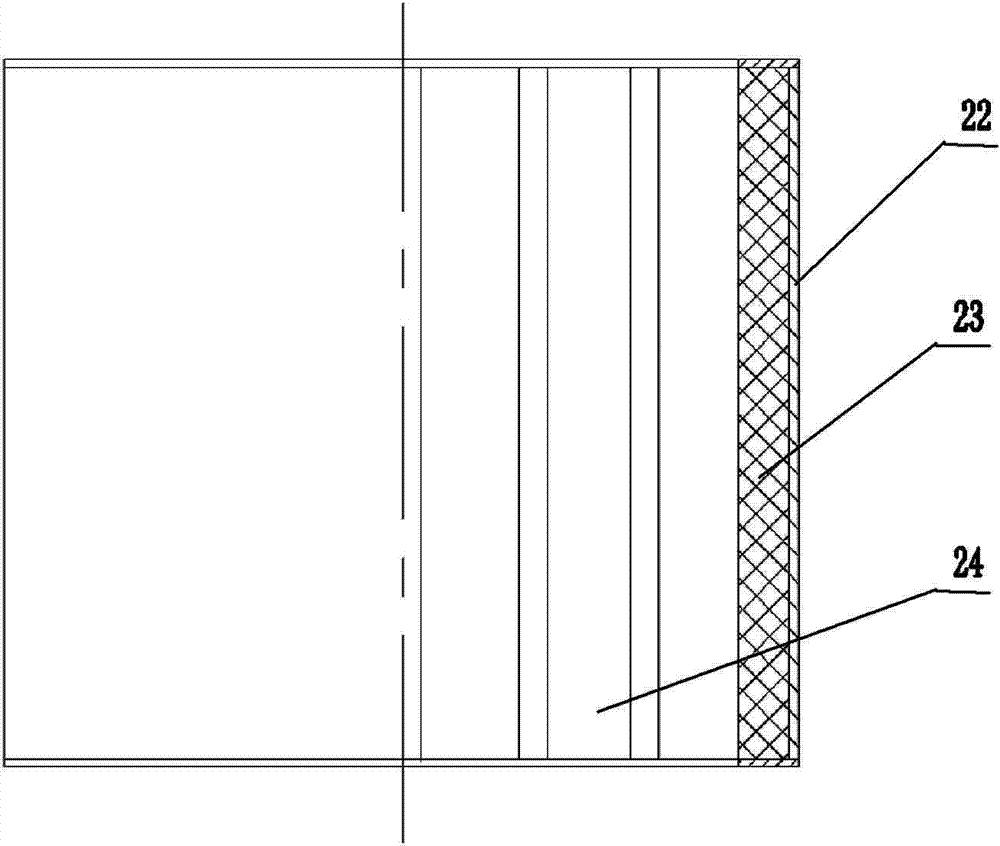

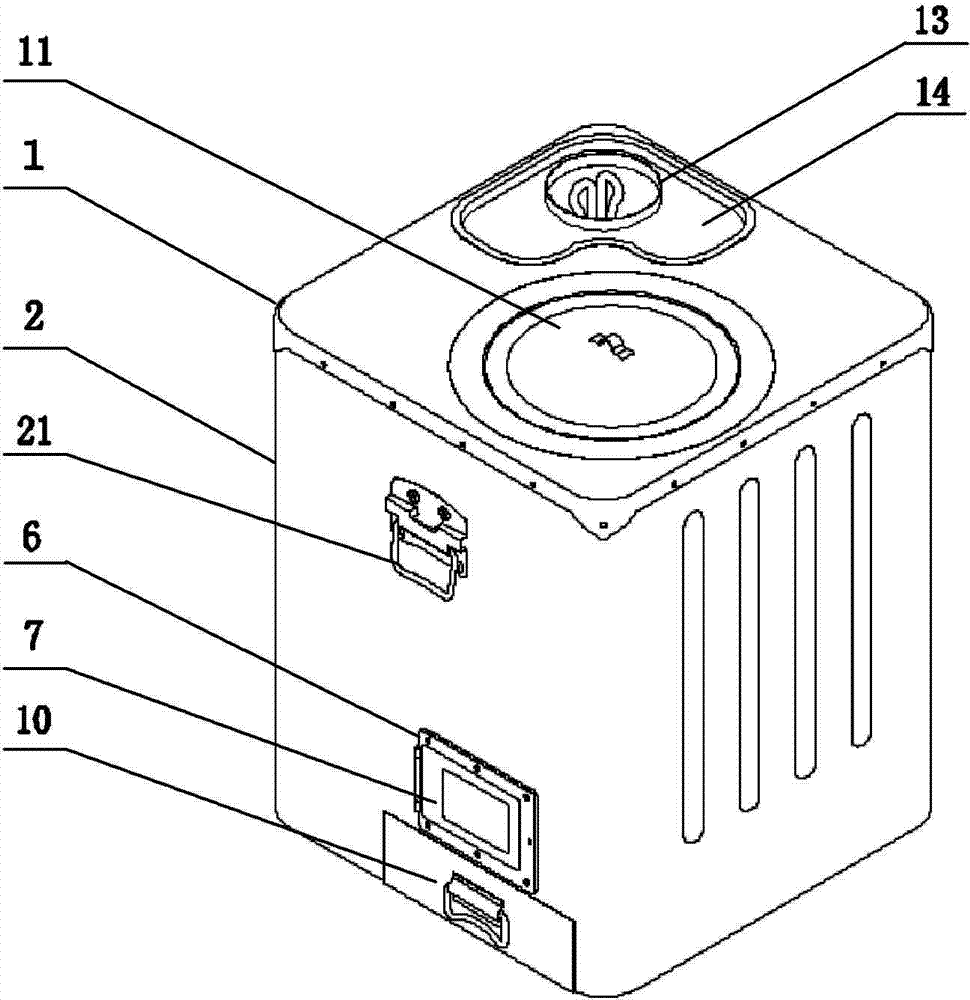

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] as attached figure 1 , attached image 3 , attached Figure 4 And attached Figure 5 , the home furnace has an outer cylinder 2, the outer cylinder 2 is a square cylinder formed by bending steel plates and welding the butt ends, and the four corners of the cylinder adopt arc angle transitions. The upper end of the outer cylinder 2 is provided with a cover 1 , the edge of the cover 1 is processed with a downward flanging, and the flange is used to connect with the outer cylinder 2 through rivets. The lower end of the outer cylinder body 2 is provided with a bottom cover plate 18, which is connected with the outer cylinder body 2 by welding, as attached figure 1 , The position of the back cover plate 18 has a certain distance from the lower end of the outer cylinder 2, so that the lower end of the outer cylinder 2 forms the foot of the home stove. Inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com