Material temperature detection and control device for sintering pellet annular cooler

A technology of control device and ring cooler, which is applied in the direction of processing discharged materials, furnace types, furnaces, etc., and can solve problems such as red ore falling, casualties, and product quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

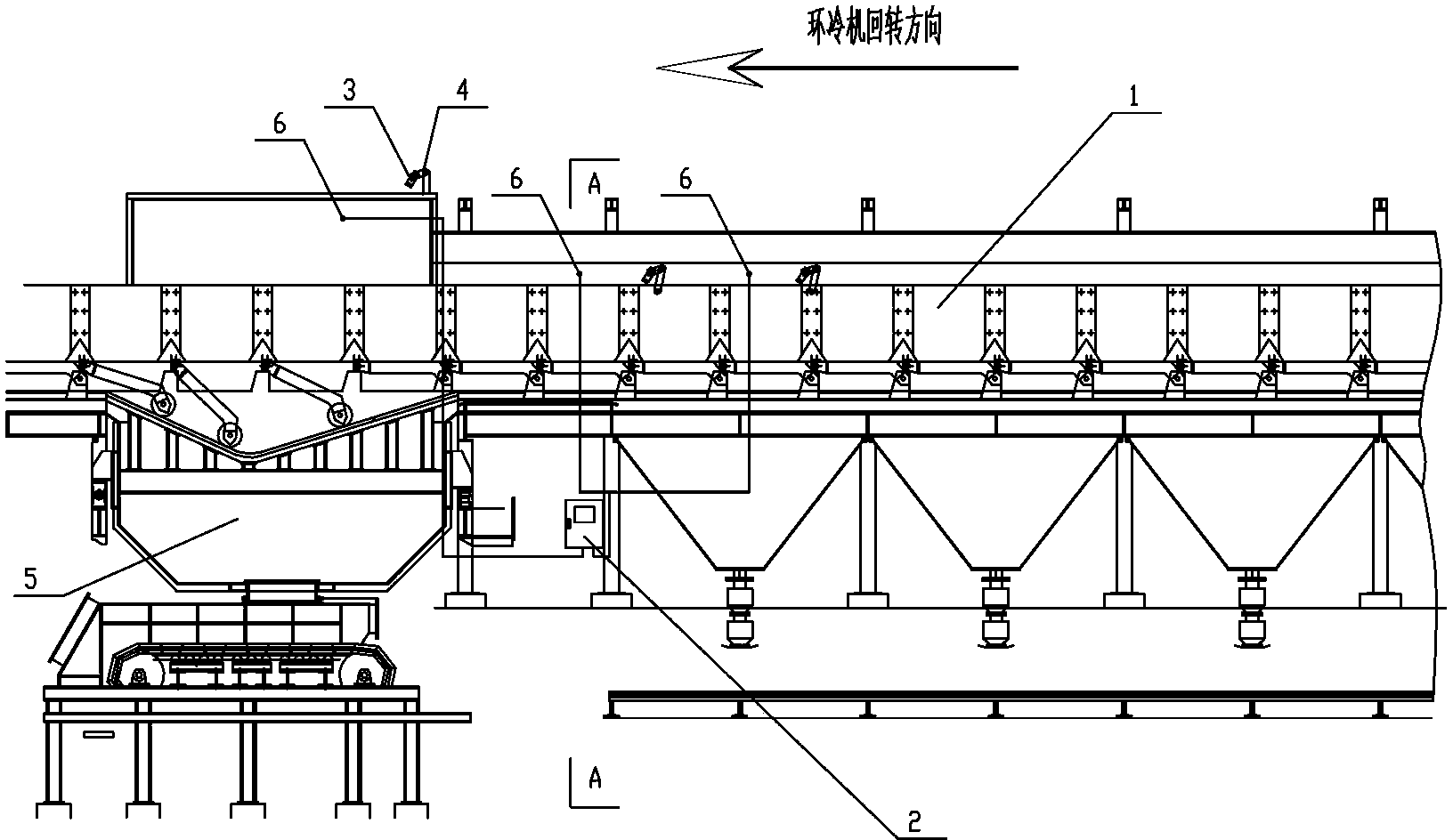

[0012] The present invention will be further described below in conjunction with accompanying drawing.

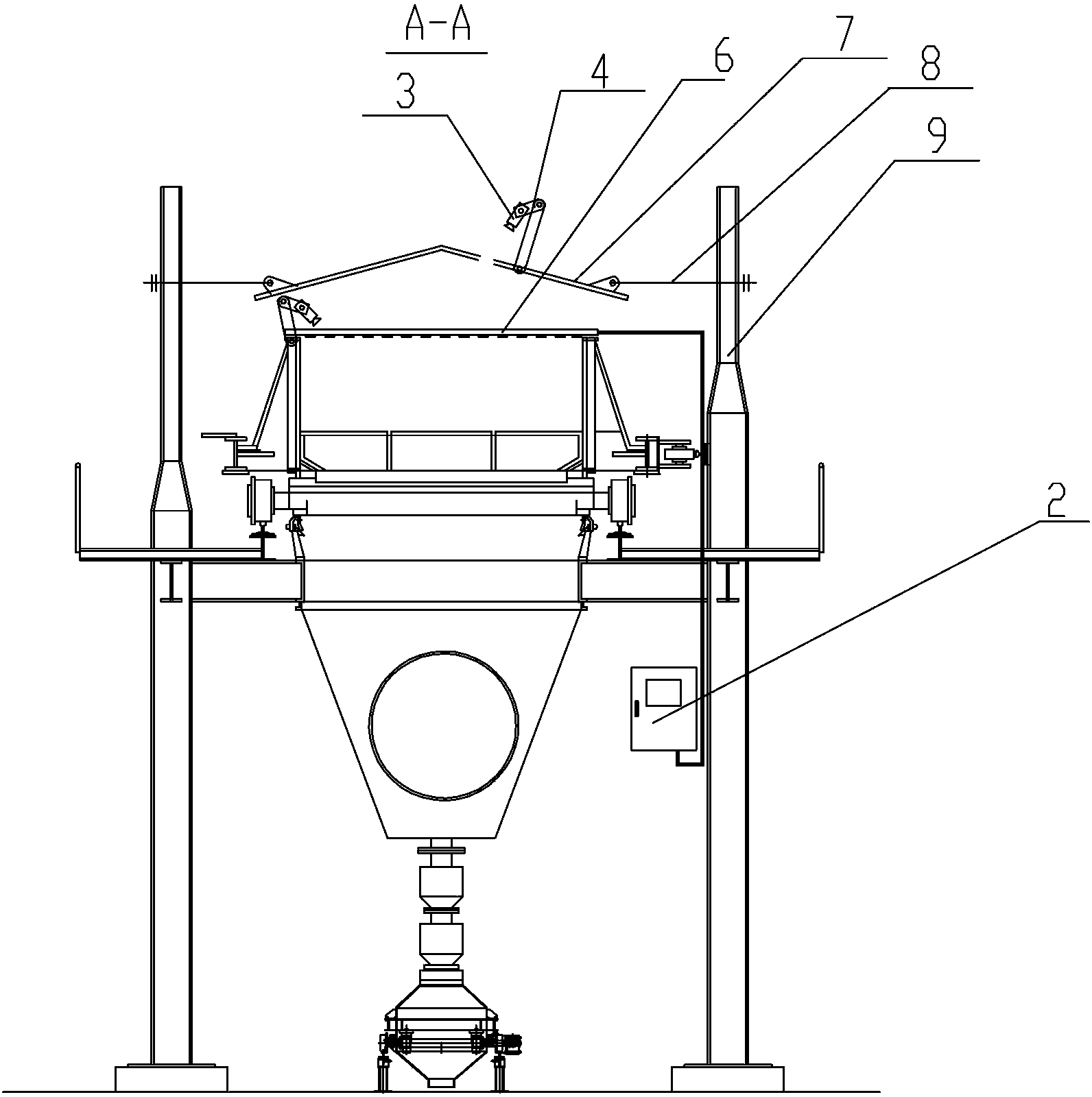

[0013] Such as figure 1 , figure 2 As shown, the temperature detection and control device for sintering pellet annular coolers of the present invention includes an annular cooler 1 and an annular cooler unloading hopper 5 connected to the tail of the annular cooler 1, which is characterized in that it also includes a heat-insulated The support device is arranged on more than one infrared thermometer 3 above the discharge port of the annular cooler, and the infrared thermometer 3 is connected with the control device 2, and is above the tail of the annular cooler and the discharge hopper of the annular cooler 5 Spray pipes 6 are respectively arranged above.

[0014] Such as figure 2 As shown, the heat insulation support device is composed of an arch heat insulation baffle 7, two support rods 8 hinged to the two ends of the arch heat insulation baffle 7 and an infrared th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com