FPGA (Field Programmable Gate Array)-based computer control active lap dynamic surface shape acquisition system and method

A collection system and dynamic surface technology, applied in the direction of using optical devices, measuring devices, instruments, etc., to achieve data integrity and improve measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

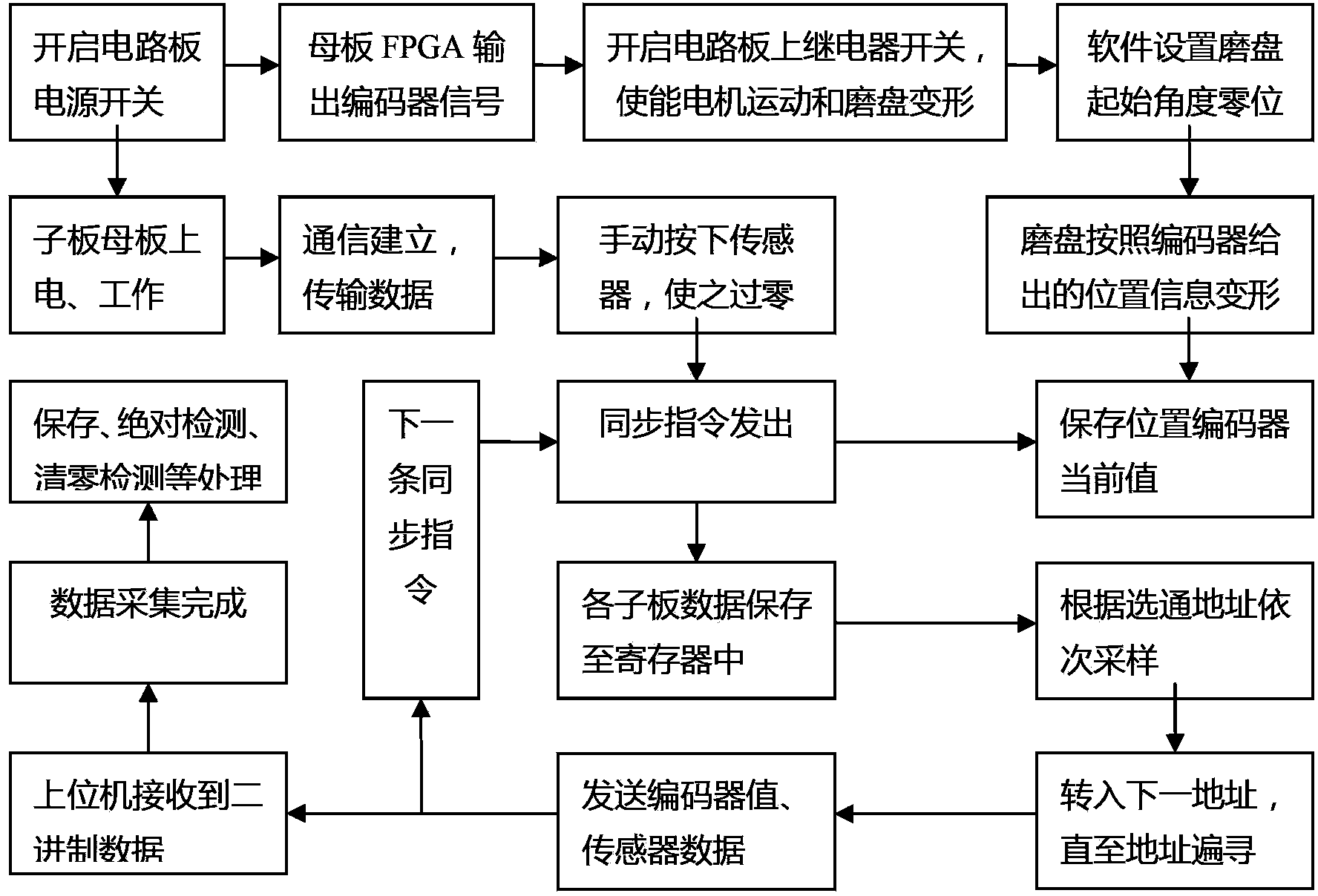

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

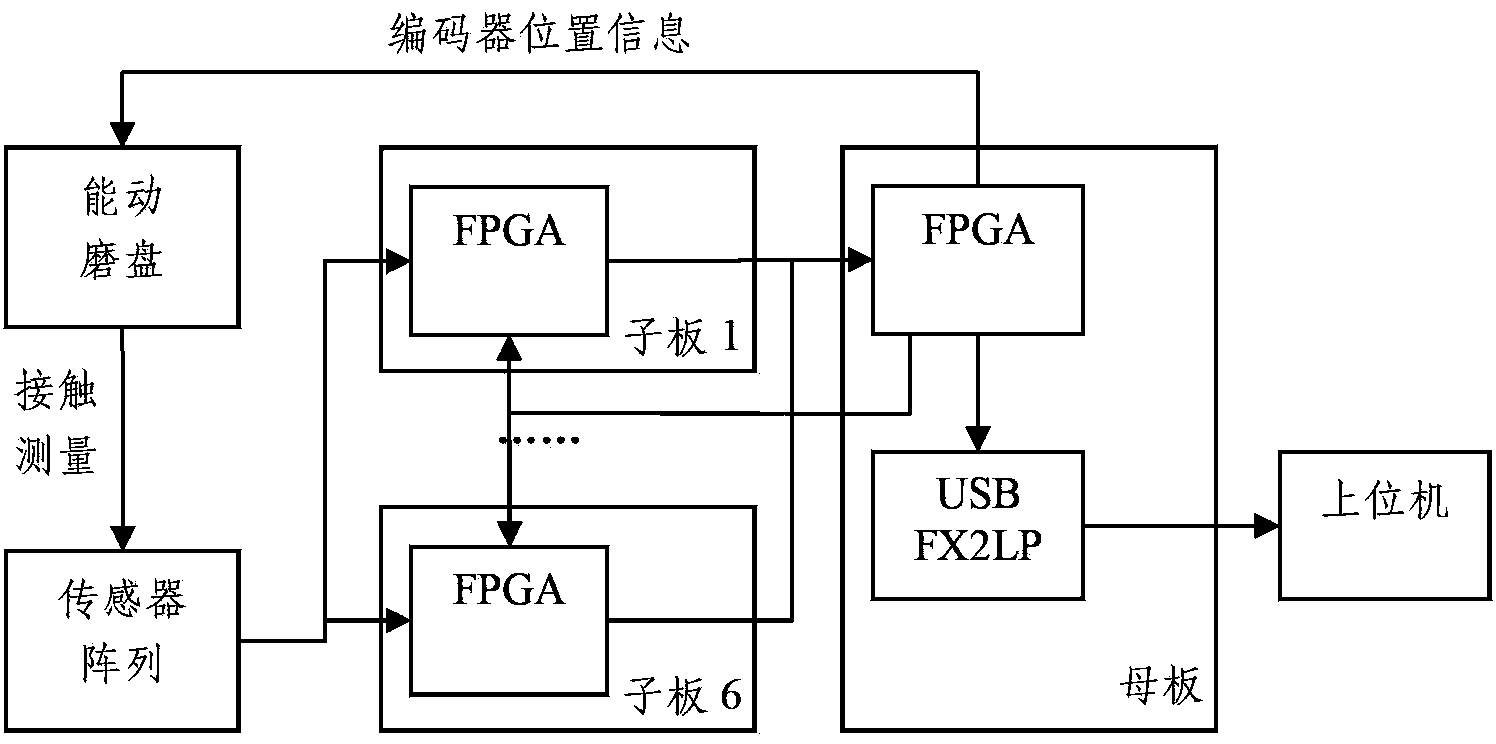

[0025] Such as figure 1 Shown, main composition of the present invention is as follows:

[0026] ① High-precision micro-displacement sensor array;

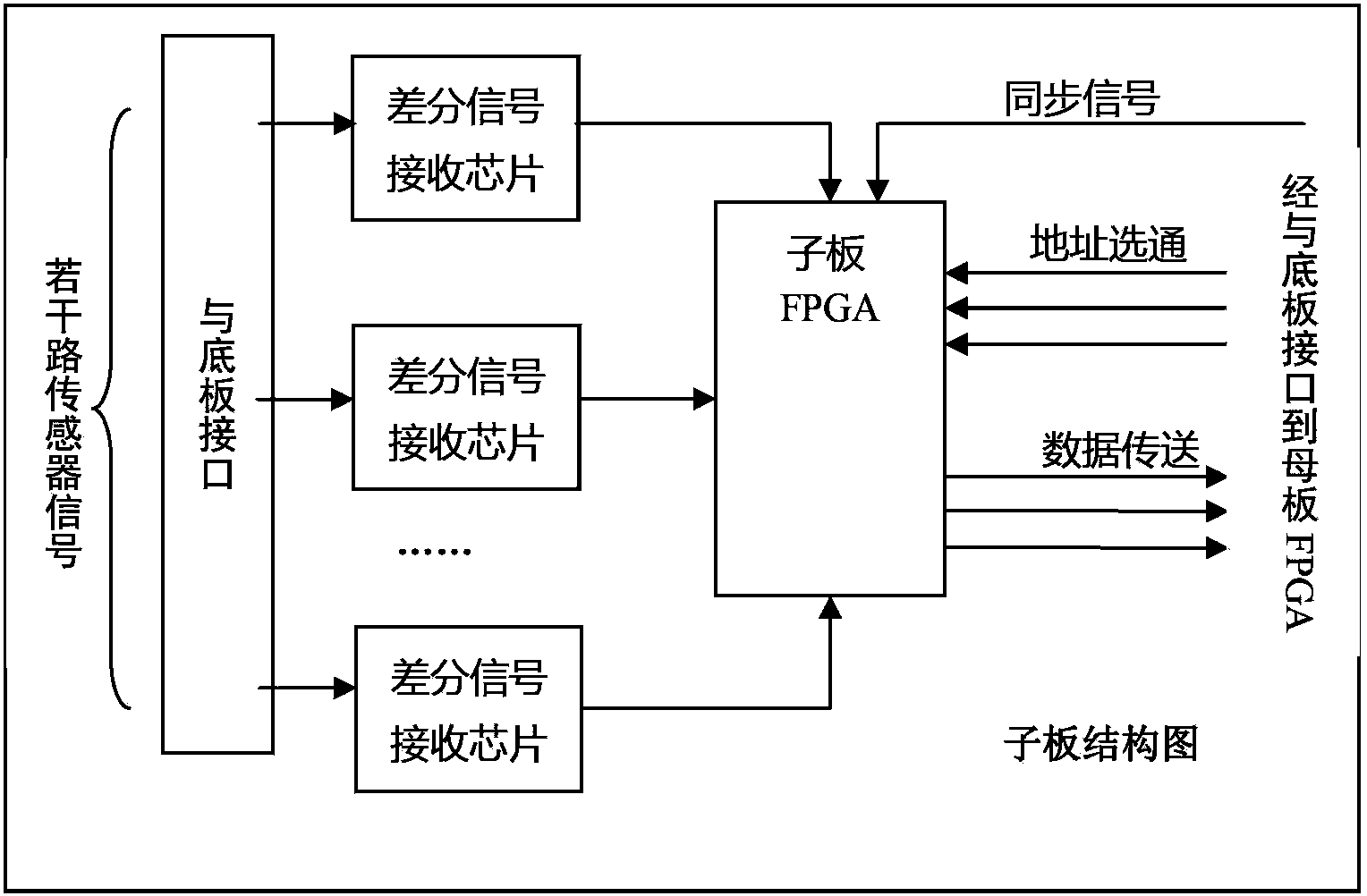

[0027] ② The sub-board responsible for collecting the signals of each sensor;

[0028] ③Responsible for generating the position information of the disc encoder, addressing each sub-board to sample each sensor data, and transmitting the encoder position information and sensor data to the motherboard of the upper computer through the USB interface.

[0029] Each sub-board is independently responsible for the data collection of several sensors in the sensor array. The number of sub-boards should be selected according to the number of sensors. figure 1 Take 6 sub-boards as an example; the main board is responsible for simulating the position information of the machine tool encoder to the dynamic grinding disc deformation co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com