Detection device for underground coal mine drill rod length and fault and using method thereof

A technology of drill pipe length and detection device, applied in the direction of measuring device, fault location, electric device, etc., can solve problems such as short circuit, seal failure at drill pipe joint, open circuit, etc., and achieve fast and accurate detection, simple and compact structure, and detection. various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

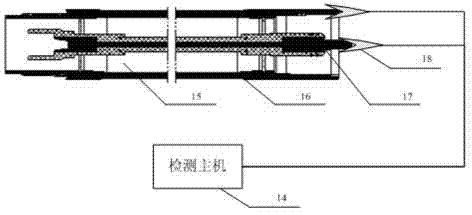

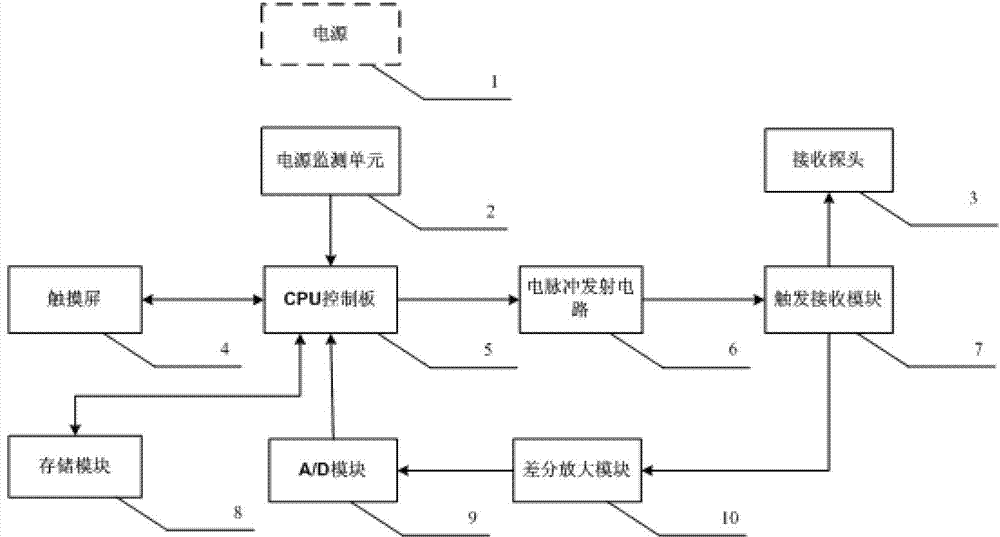

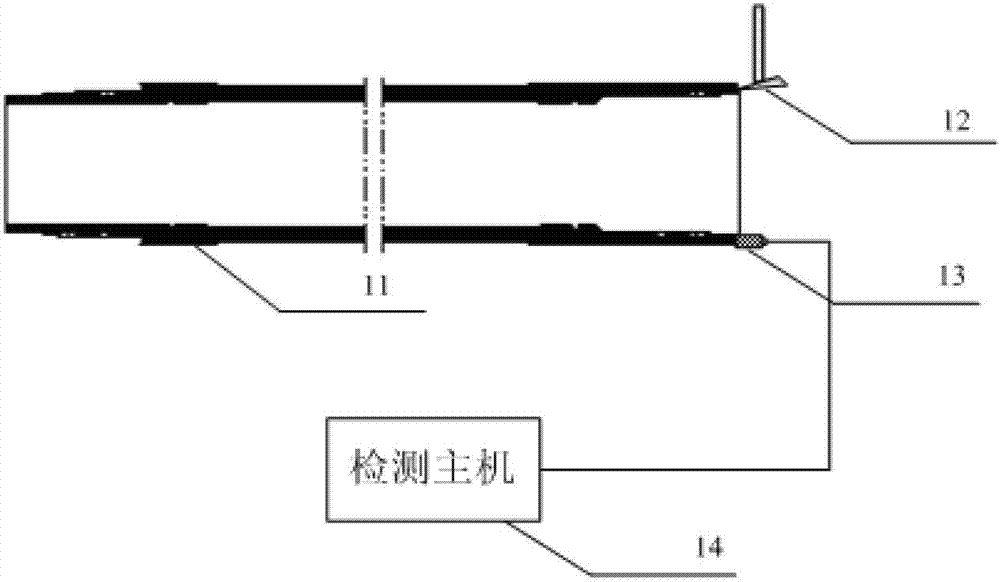

[0026] see Figure 1-3 , shows the coal mine underground drill pipe length and fault detection device of the present invention, the detection device includes a power supply module, a control module, a detection module and a signal processing module and the like.

[0027] The power supply module contains power supply 1 to supply power to other modules, and the power supply can provide 5V, 3.3V and 1.5V power supply for the whole device for Ni-MH batteries.

[0028] Preferably, the power supply module can also include a power detection unit to monitor the voltage and current of the power supply 1 .

[0029] The detection module includes a receiving probe 3 and a trigger receiving module 7, the receiving probe 3 may include an acoustic wave receiving probe 13 or a clip line 18, the trigger receiving module 7 is connected to the receiving probe 3 to trigger the opening and closing of the receiving probe 3 and receiving the detection signal, and the trigger receiving module 7 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com