Columnar forming device for concrete materials

A molding device and concrete technology, which is applied in the preparation of test samples, etc., can solve the problems of uneven surface of material rods, large manpower and time consumption, cumbersome and complicated assembly and disassembly processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

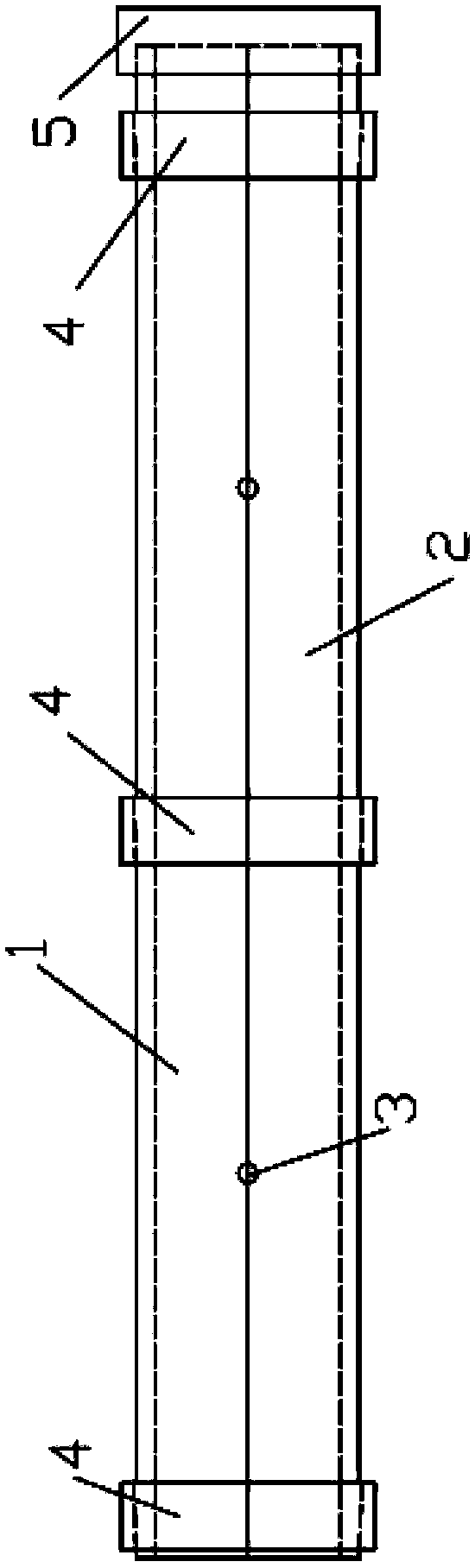

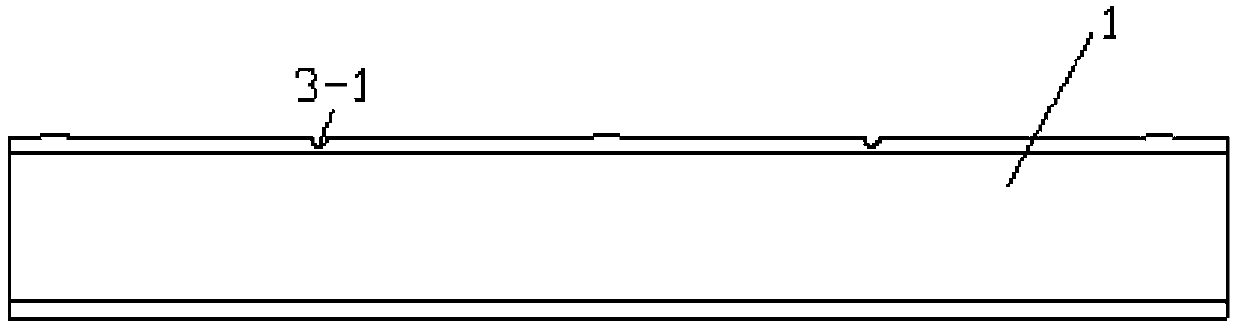

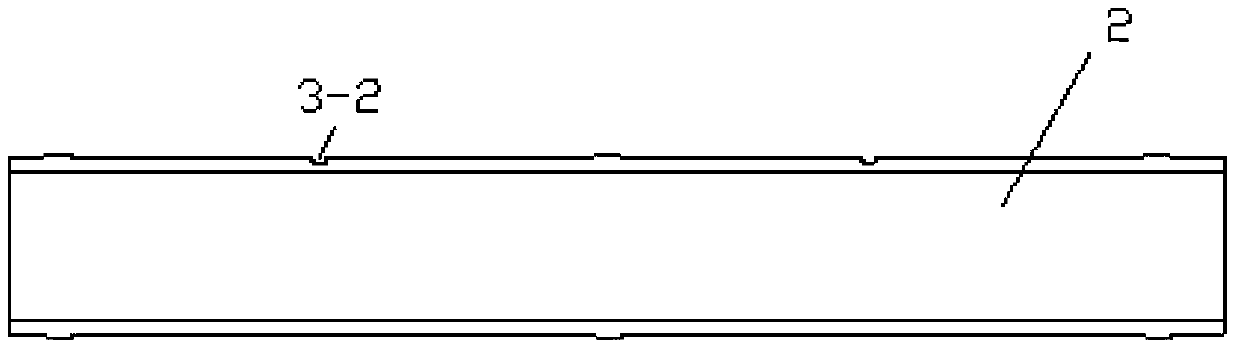

[0028] A columnar forming device for concrete materials, including a pouring mold with a tubular structure. The casting mold is divided into two semicircles with the center line as the base point, which are respectively an upper mold 1 and a lower mold 2. The upper mold and the lower mold have the same structure and are connected. The casting mold There is a split hole 3 on the top, and the effect of the split hole is to facilitate the separation of the upper mold and the lower mold after the cement pouring is formed. At least one upper split hole is provided on the tube wall at the axial free end of the upper die, and the lower split hole is also provided at the corresponding position of the lower die. After the upper die and the lower die are connected to form a complete tubular structure, the upper split hole and The lower split hole also forms a full split hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com