Novel suspension type freeze concentration equipment

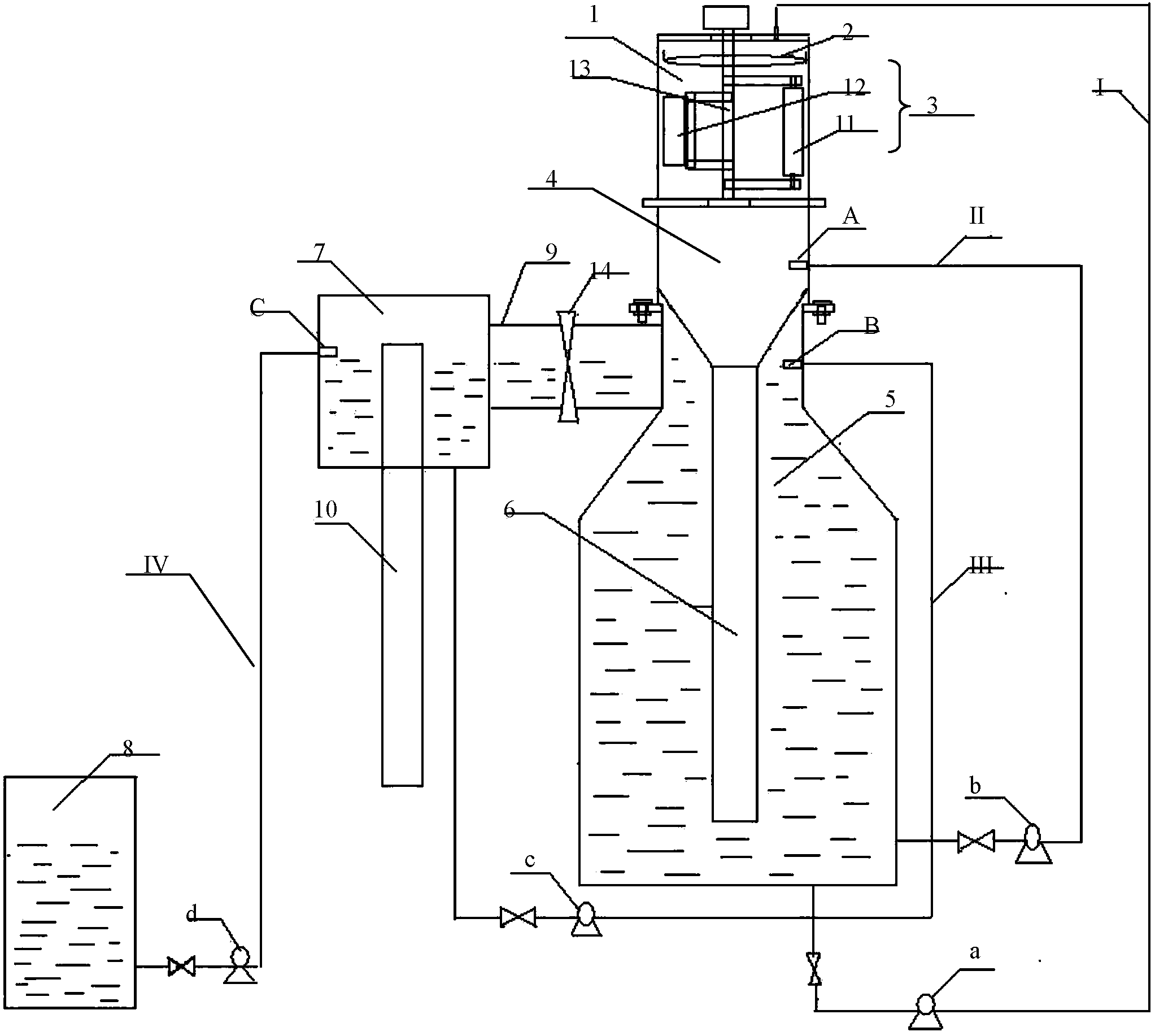

A freeze-concentration and suspension technology, applied in the processing field, can solve the problems of difficult to control the thickness of the ice layer and high ice crystal entrainment, and achieve the effect of being conducive to large-scale production and application, less control conditions, and reducing the entrainment rate of ice crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0037] Case 1:

[0038] In this example, abalone organ polysaccharide solution with a concentration of 1% is used as the raw material (the concentration is calculated as the concentration of soluble solids), and the suspension freeze-concentration treatment is carried out. The specific steps are as follows:

[0039] (1) Place the abalone organ polysaccharide liquid with a concentration of 1% in the recrystallization tank 5 first, and make the liquid level in the recrystallization tank 5 slightly lower than that in the ice discharge tank 7, close the valve 14, and open the pump a. , start the material circulation system, pump the liquid into the liquid distribution plate 2, the distribution plate rotates under the drive of the reducer, the liquid flows out from the small holes in the plate wall and is thrown to the inner surface of the scraper heat exchanger 1 and flows down along the wall. For heat exchange, set its temperature to -20°C.

[0040] (2) Start the ice scraping de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com