Apparatus for catalytic conversion of methane by utilizing visible light

A catalytic conversion and visible light technology, applied in the field of chemical engineering, can solve limitations and other problems, and achieve the effects of light specific gravity, large effective light area, improved mass transfer efficiency and degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

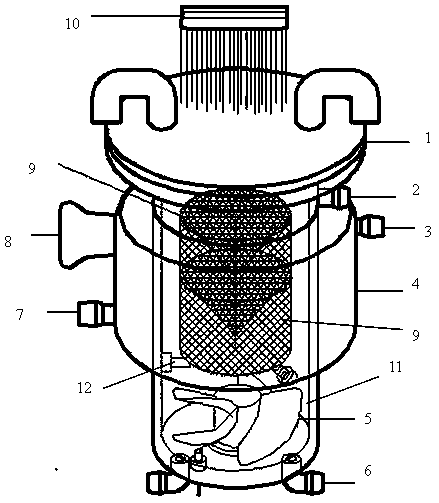

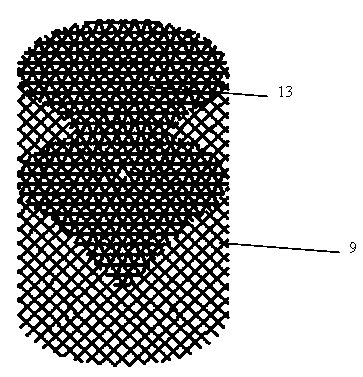

[0028] Such as figure 1 and figure 2 As shown in the present invention, a device for catalytic conversion of methane using visible light includes a cylinder 11, a support 12 is arranged inside the cylinder 11, and a titanium mesh 9 is arranged on the support 12, and the A catalyst is arranged on the titanium mesh 9, and the catalyst is BiVO 4 Powder, the lower part of the support 12 is provided with a fan 5, the upper end of the cylinder 11 is provided with a light-transmittable cover 1, and a light source 10 is provided on the vertical direction of the cover 1. The outer circumference of the cylinder 11 is provided with a water sleeve 4, the water sleeve 4 is airtightly connected with the cylinder 11, and the upper part of the side wall of one side of the water sleeve 4 is provided There is a water inlet 3, the lower part of the side wall on the other side of the water casing 4 is provided with a water outlet 7, and the bottom of the cylinder 11 is provided with at least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com