Safe disposal method for high-concentration arsenic residue

A disposal method and high-concentration technology, applied in the field of ecological environmental protection, can solve the problems of lack of safe disposal of high-concentration arsenic-containing waste residues, in-depth research, etc., and achieve the effect of large treatment capacity, good repair effect and short repair period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

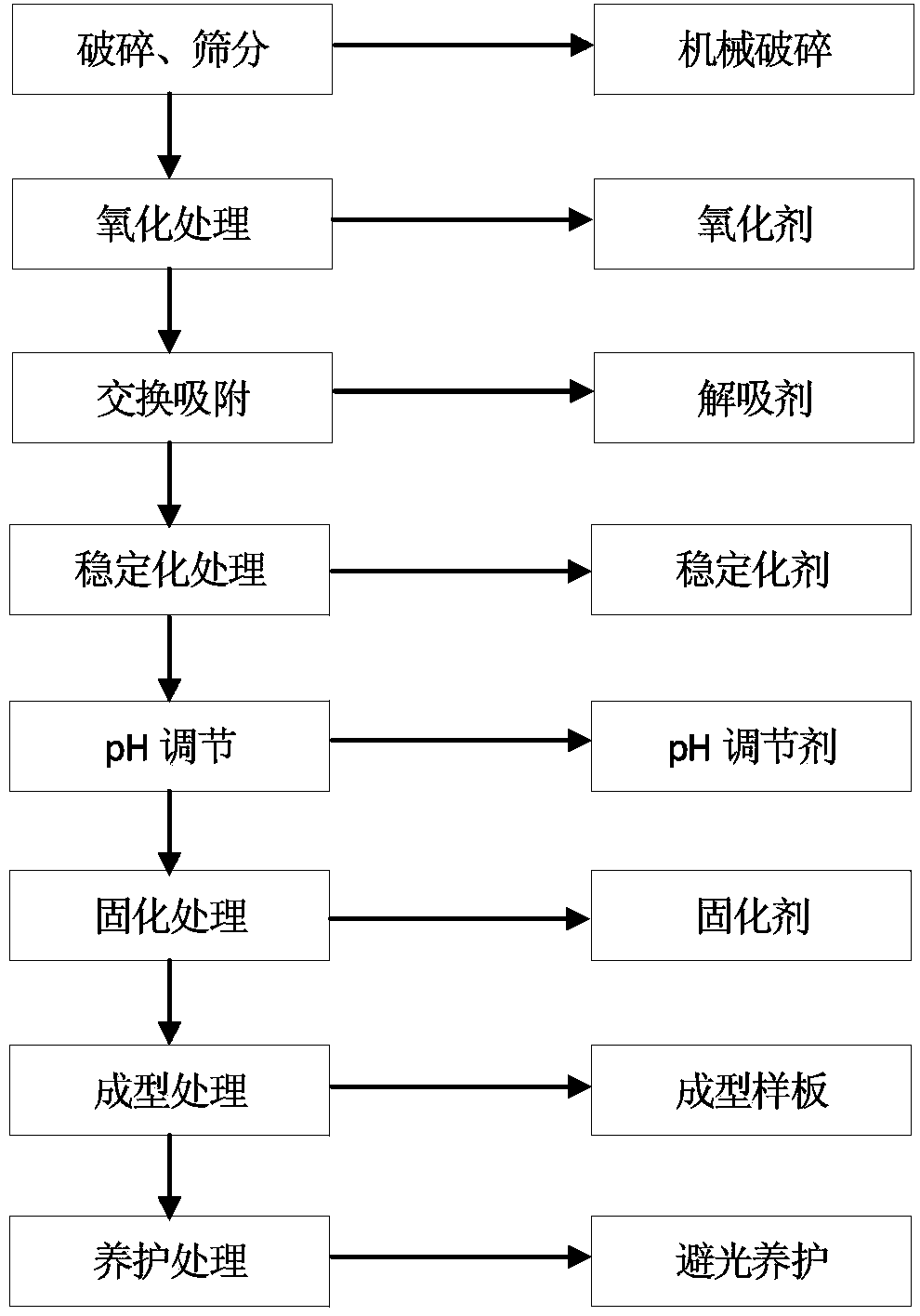

[0030] see figure 1 , discloses a flow chart of specific steps of the safety disposal method according to the present invention. The method can physically and chemically safely dispose of high-concentration arsenic-containing waste residues produced in the production process of industrial enterprises or left over from abandoned industrial enterprises. The method includes the following steps:

[0031] (1) Crushing and screening: crushing and screening high-concentration arsenic-containing waste residues.

[0032] (2) Oxidation treatment: add a certain proportion of oxidant to the high-concentration arsenic-containing waste residue, and then add a certain proportion of water to fully stir the mixture.

[0033] (3) Exchange adsorption process: add a certain proportion of desorbent to the high-concentration arsenic-containing waste residue, and fully stir and mix the mixture.

[0034] (4) Stabilization process: add a certain proportion of stabilizer, then add a certain proportio...

Embodiment 2

[0050] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

[0051] The total analysis of arsenic adopts the atomic fluorescence method of "Identification Standard for Hazardous Wastes_Toxic Substances Content Identification" (GB5085.6-2007), and the analysis method of toxic leaching test adopts "Solid Waste_Leaching Toxicity Leaching Method_Sulfuric Acid Nitric Acid Method" (HJ-T299- 2007) Appendix E: P32-34. The reference standard for product toxicity and leaching indicators is the "Hazardous Waste Landfill Pollution Control Standard" (GB18598-2001).

[0052] The specific implementation steps are shown in the figure below ( figure 1 ) shown.

[0053] (1) Crushing and screening: referring to the systematic sampling method in the "Technical Specifications for Industrial Solid Waste Sampling" (HJ-T20-1998), a certain arsenic production plant samples the industri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com