Waterproof antifouling numerical control electrical discharge wire cutting machine tool

A technology of cutting machine tools and electric spark wires, applied in the direction of electric processing equipment, metal processing equipment, accessory devices, etc., can solve the problems of easy aging of wires and electrical appliances, electrical failure, and failure to work, so as to achieve low cost, avoid electrical short circuit, good promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

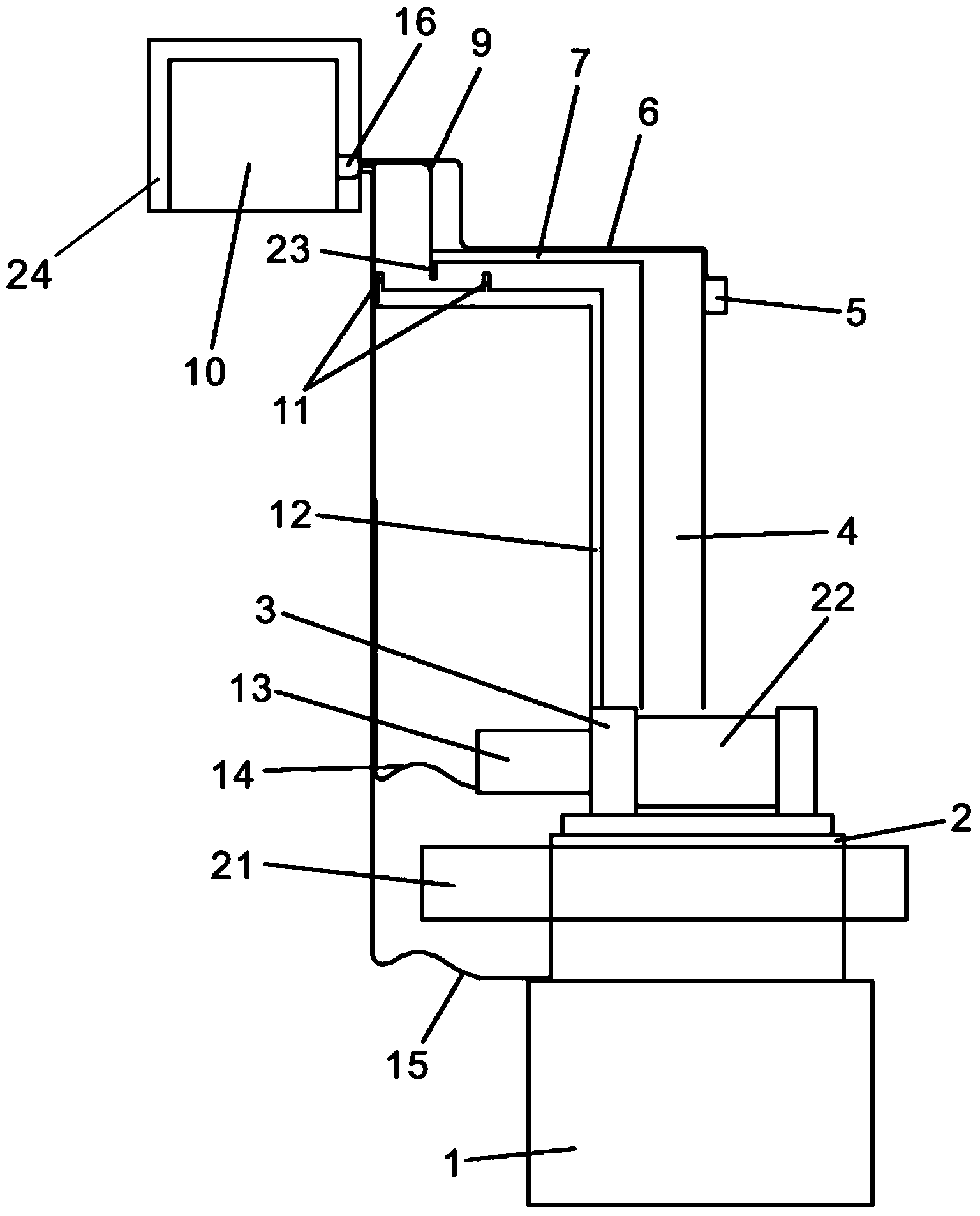

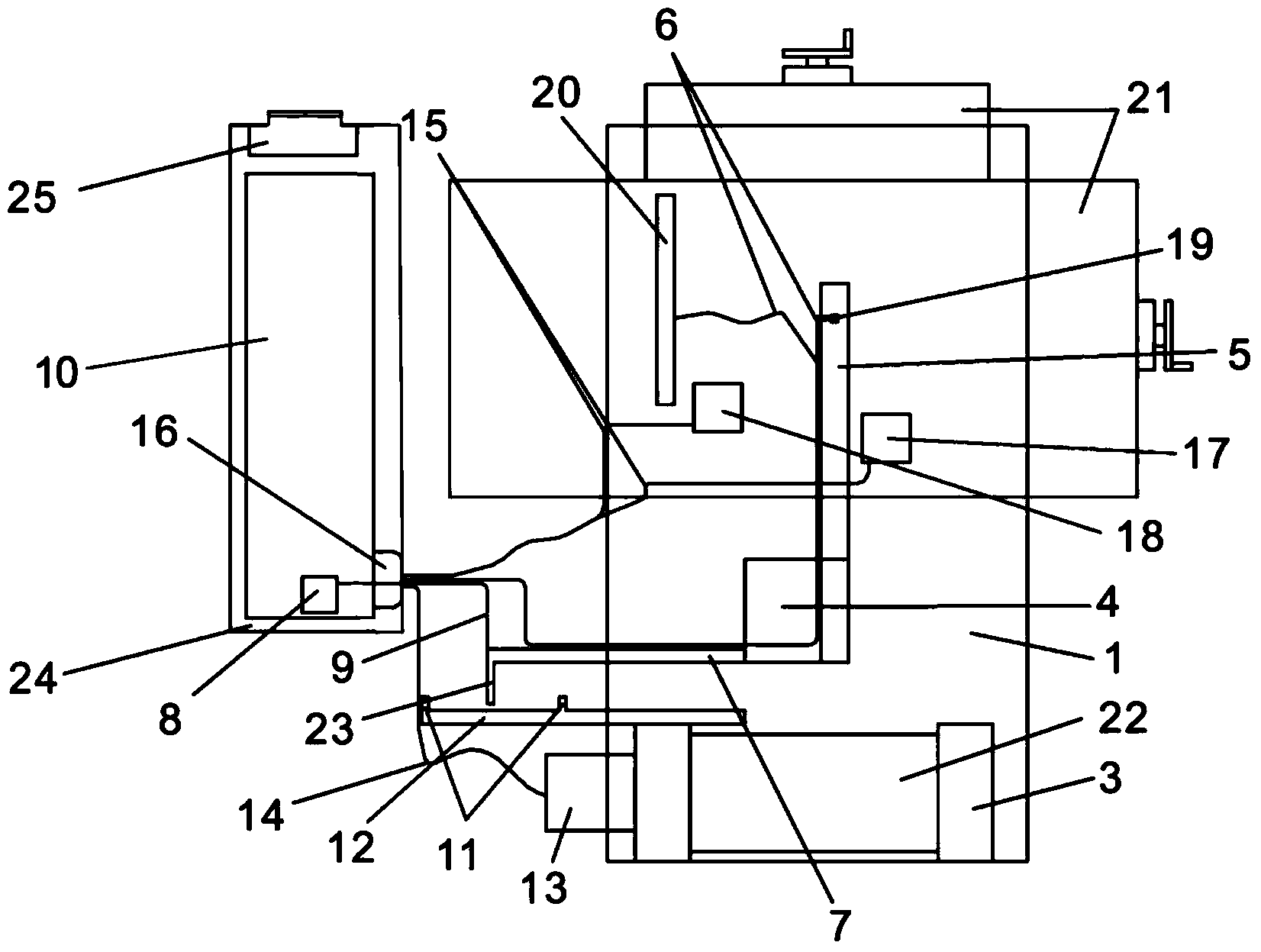

[0026] refer to Figure 1 to Figure 2 ,like figure 1 and figure 2 A waterproof and antifouling numerically controlled wire-cutting electric discharge machine tool shown includes a fuselage 1, a cross carriage 21 arranged on the fuselage 1 and a wire stand column 4 fixed on the fuselage 1, the wire stand column 4. The upper part is provided with an upper and lower wire arm 5, and also includes a lower base 2 of the winding drum fixed on the fuselage 1, and an upper base 3 of the winding drum is fixed on the lower base 2 of the winding drum. The base 3 on the drum is provided with a wire winding drum 22, and also includes an electrical control box 10 arranged on one side of the fuselage 1, and the wire stand column 4 is also provided with a fixed induction head frame 7. The base 3 is also provided with a silk tube travel positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com