Manufacturing method of glass fiber floorboards

A glass fiber and manufacturing method technology, applied in the field of floor manufacturing, can solve the problems of weak artificial bonding fastness, short service life, troublesome process, etc., and achieve the effects of small shrinkage rate, cost saving of raw materials, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

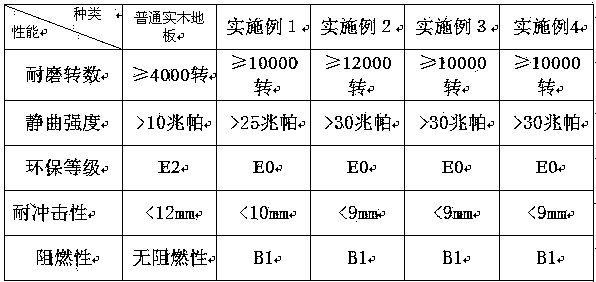

Examples

Embodiment 1

[0048] A kind of manufacturing method of fiberglass floor, can produce the floor of any standard specification on the existing market, for example: make the finished floor whose total thickness is 8mm, the thickness of the decorative plate is 3mm, and the distance from the edge of the decorative plate to the outer edge of the floor is 2mm, The inner cavity height of steel mold 1 selected is 7mm, and the inner cavity height of steel mold 2 is 8mm. The detailed processing steps are as follows:

[0049] (1) Place the decorative plate on the bottom of the groove mold 1 with a fixing device at the bottom and fix it. The distance from the decorative plate to the inner wall of the steel mold 1 is 2mm;

[0050] (2) Add glass fiber and resin to the groove mold 1, the weight ratio of the two is: 90% glass fiber, 10% resin, and make the two fully mixed, and crystallize to obtain the decorative plate on the bottom surface floor substrate slabs;

[0051] (3) Place the floor substrate sla...

Embodiment 2

[0058] The difference from the above-described embodiment is that the thickness of the veneer or solid wood slab, that is, the decorative board, is 12mm, and the thickness of the finished floor is 16mm. When the decorative board is placed in the steel mold one, the distance from its edge to the steel mold one inner wall is 6 mm. mm, the height of the first cavity of the steel mold is 0.6mm higher than the height of the second cavity of the steel mold, the thickness of the transparent glass fiber cloth is 0.3mm, and the total thickness of the mixed glass fiber, resin and nano-ceramic particles added 0.3mm. The weight ratio of glass fiber and resin in step (2) is: glass fiber 97%, resin 3%; the weight ratio of glass fiber, resin and nano-ceramic particles added in step (4) is: glass fiber 95%, 4% resin, 1% nano ceramic particles. After the floor substrate slabs and floor substrates in steps (2) and (4) are formed, they are placed in an environment with a temperature of 0 degree...

Embodiment 3

[0061] Difference with above-mentioned embodiment is: the thickness of veneer or solid wood slab i.e. decorative board is 1mm, the thickness of the finished product floor of making is 10mm, and when decorative board is placed in steel mold one, the distance from its edge to steel mold inner wall is 2mm, The height of the first cavity of the steel mold is 0.7mm higher than the height of the second cavity of the steel mold, the thickness of the transparent glass fiber cloth is 0.3mm, and the total thickness of the added glass fiber, resin and nano-ceramic particles mixed is 0.4mm. mm. The weight ratio of glass fiber and resin in step (2) is: glass fiber 95%, resin 5%; the weight ratio of glass fiber, resin and nano-ceramic particles added in step (4) is: glass fiber 90%, 8% resin, 2% nano ceramic particles. After the floor substrate slabs and floor substrates in steps (2) and (4) are formed, they are placed in an environment with a temperature of 40 degrees for 25 minutes and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com