Multipurpose adjustable chamber-free vacuumizing thermal bag sealing device

A technology for vacuuming and sealing bags, which is applied in the field of multi-purpose adjustable chamberless vacuuming and heat-sealing bag devices, can solve the problems of different shapes of packaging bags, poor packaging appearance, and inability to achieve universal use, and achieves good packaging quality and use. The effect of long life and labor-saving transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

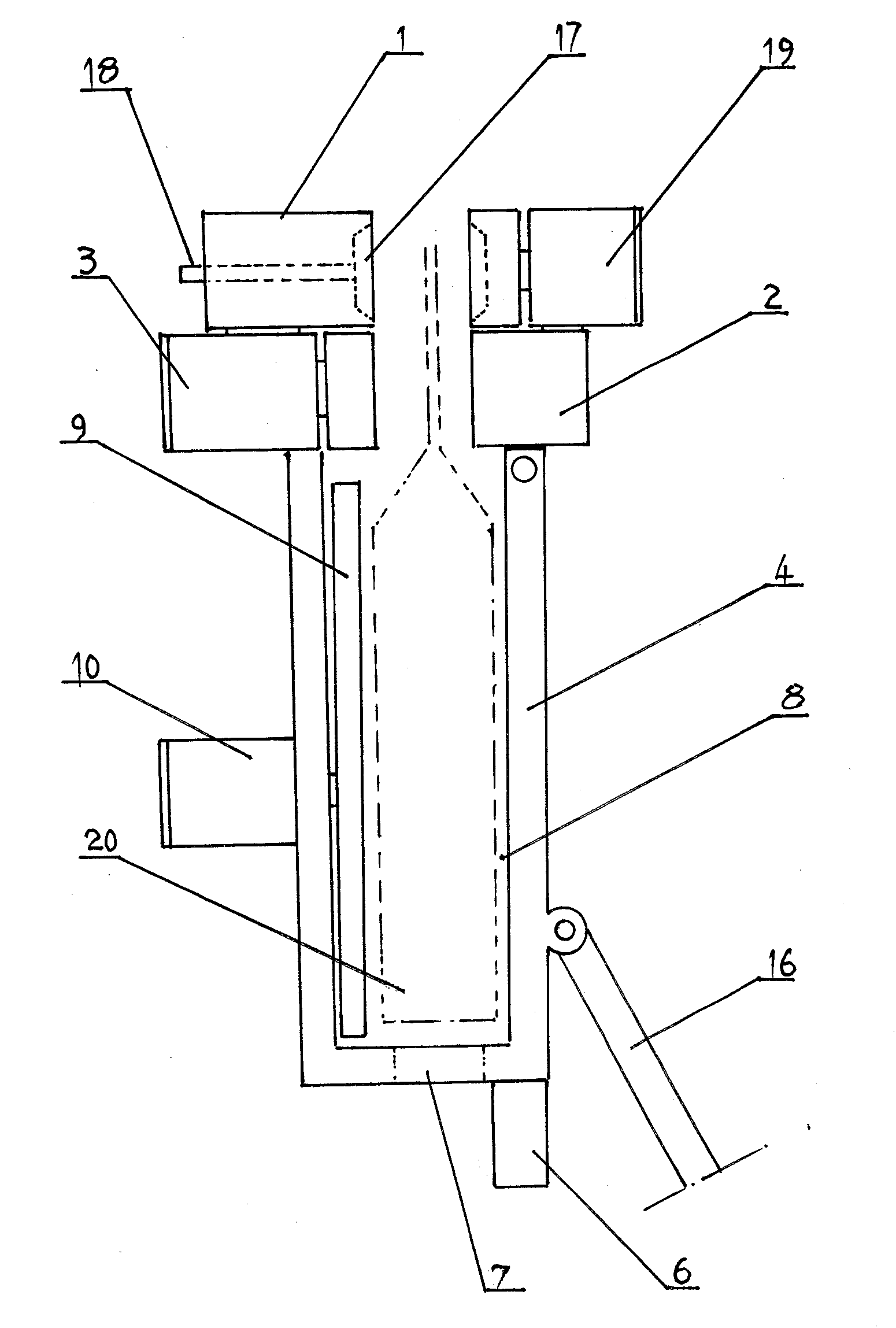

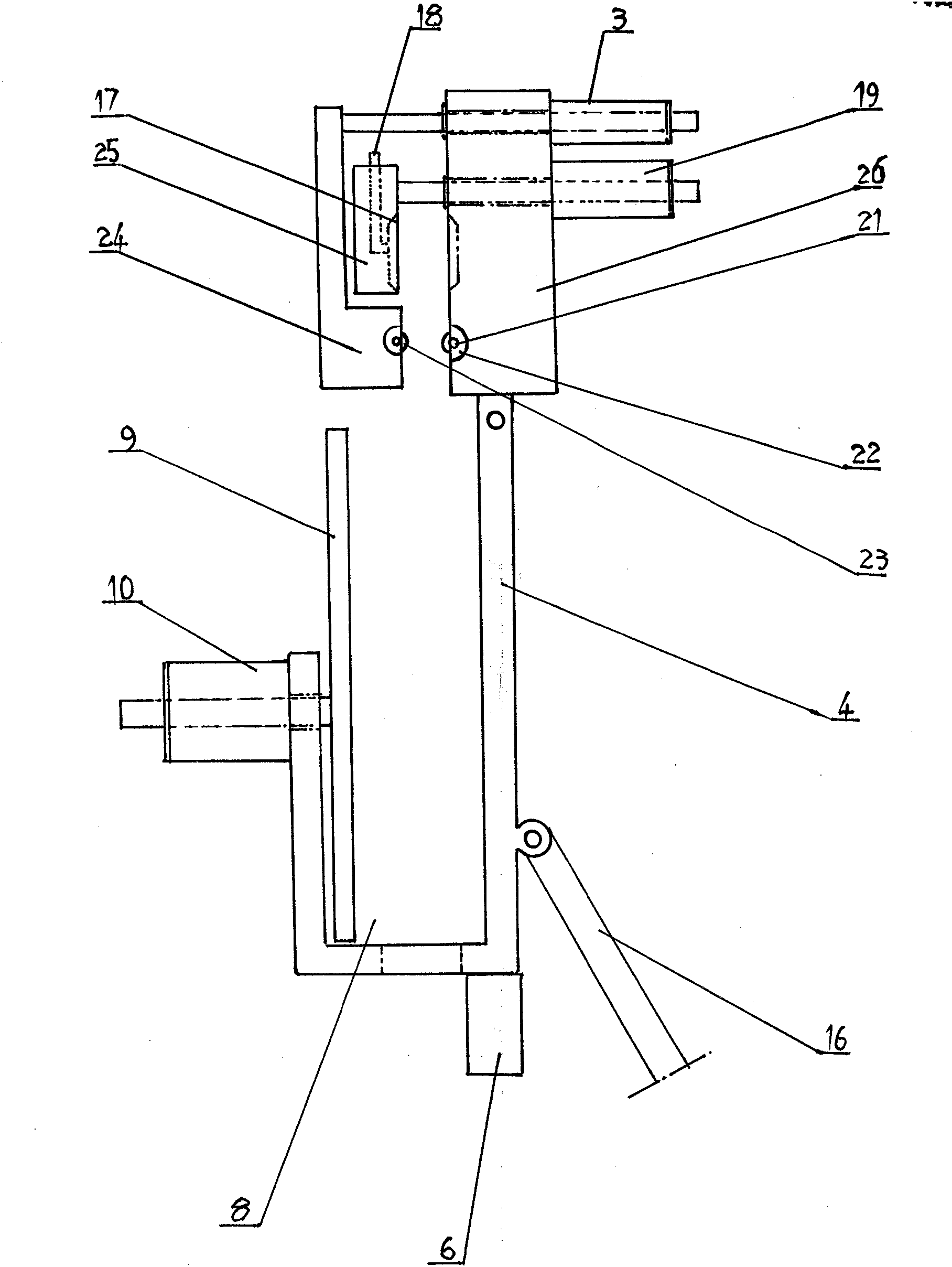

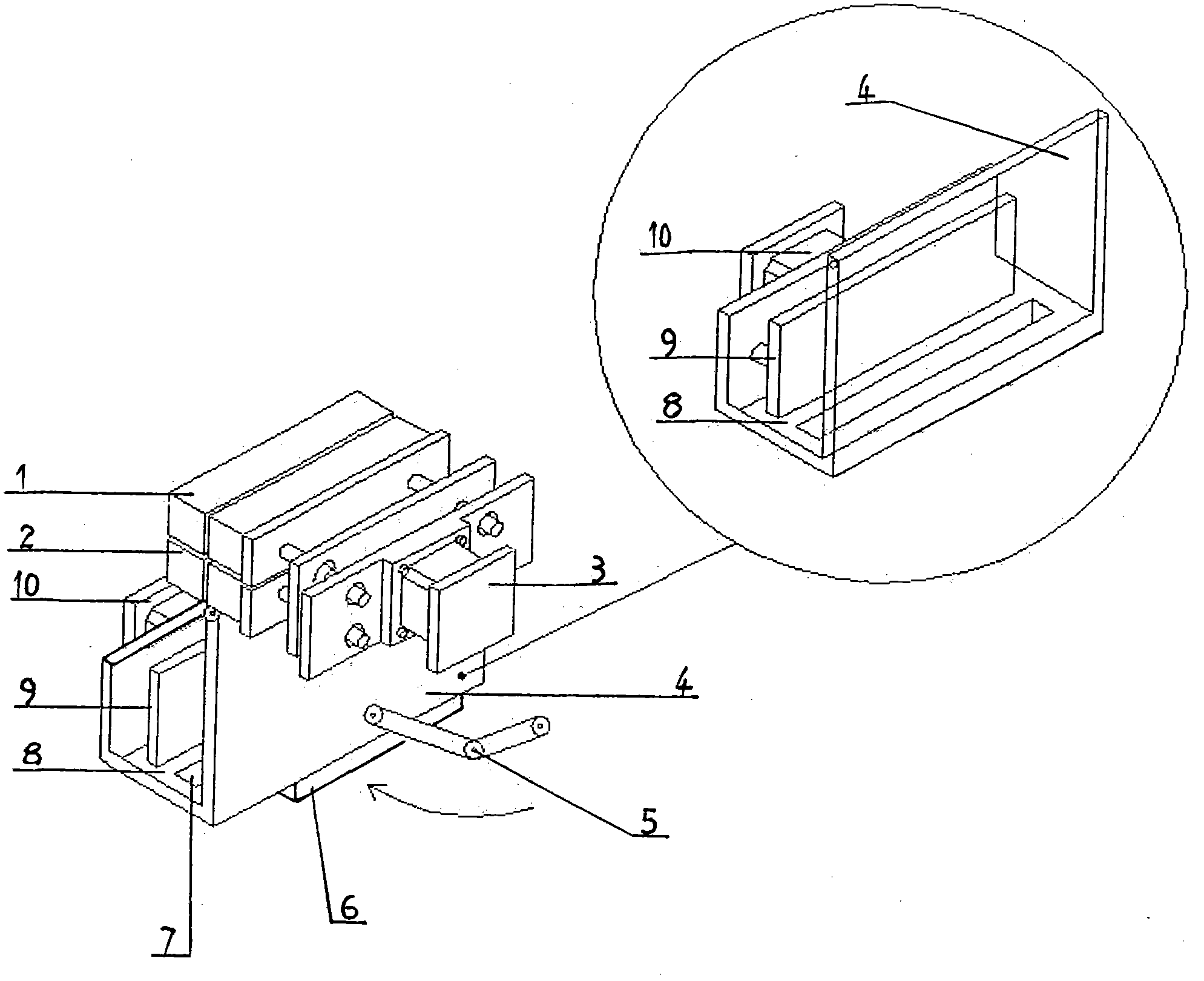

[0013] Such as Figure 1 to Figure 3 As shown, a multi-purpose adjustable chamberless vacuum heat-sealing bag device includes a suction splint and a heat-sealing splint.

[0014] The filled and opened packaging bag 20 is removed from the conveying chain by a mechanical clip and placed in the bag storage groove of the multi-purpose adjustable chamberless vacuum heat-sealing bag device, so as to Complete the final procedures of vibration, flattening, vacuuming and sealing.

[0015] Such as Figure 1 to Figure 2 As shown, the multi-purpose adjustable chamberless vacuum heat sealing bag device is a storage bag groove 8 for packaging bags to be inserted. The pocket 7 is set at the lower end of the pocket groove. The lower end of the lower pocket mouth communicates with the finished product outlet. One side of the pocket groove is a positioning baffle 4, and a vibrator 6 is established at the lower end of the locating baffle. The both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com