Control method realizing CANON process high-efficiency stable operation

A technology of stable operation and control method, applied in the field of urban sewage treatment and regeneration, can solve the problems of unrealizable, limited denitrification efficiency, high free ammonia, etc., to effectively suppress NOB, be flexible and easy to adjust, and achieve long-term efficient and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

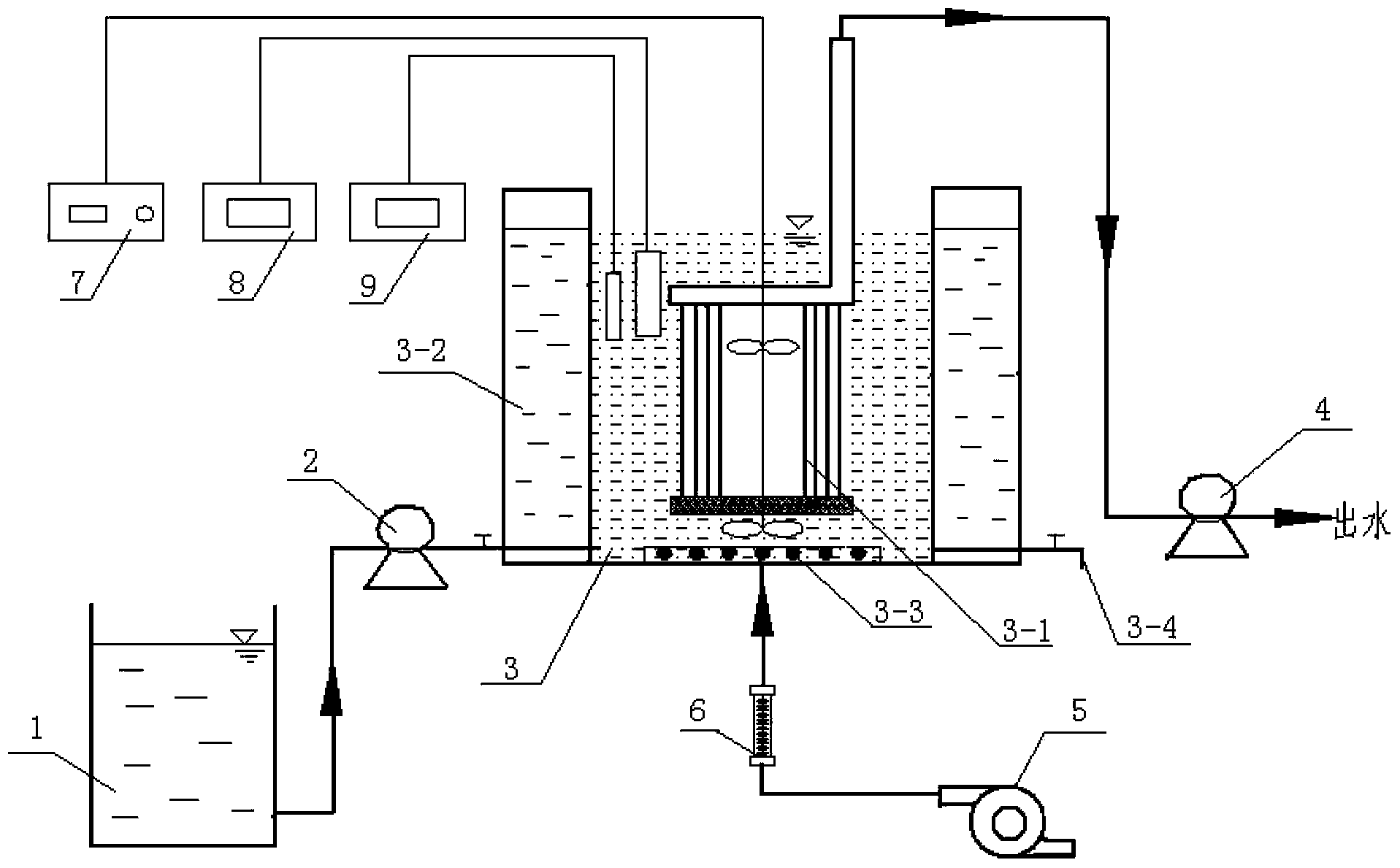

[0019] Specific implementation mode one: the specific steps of the control method for realizing the efficient and stable operation of the CANON process in this embodiment are as follows:

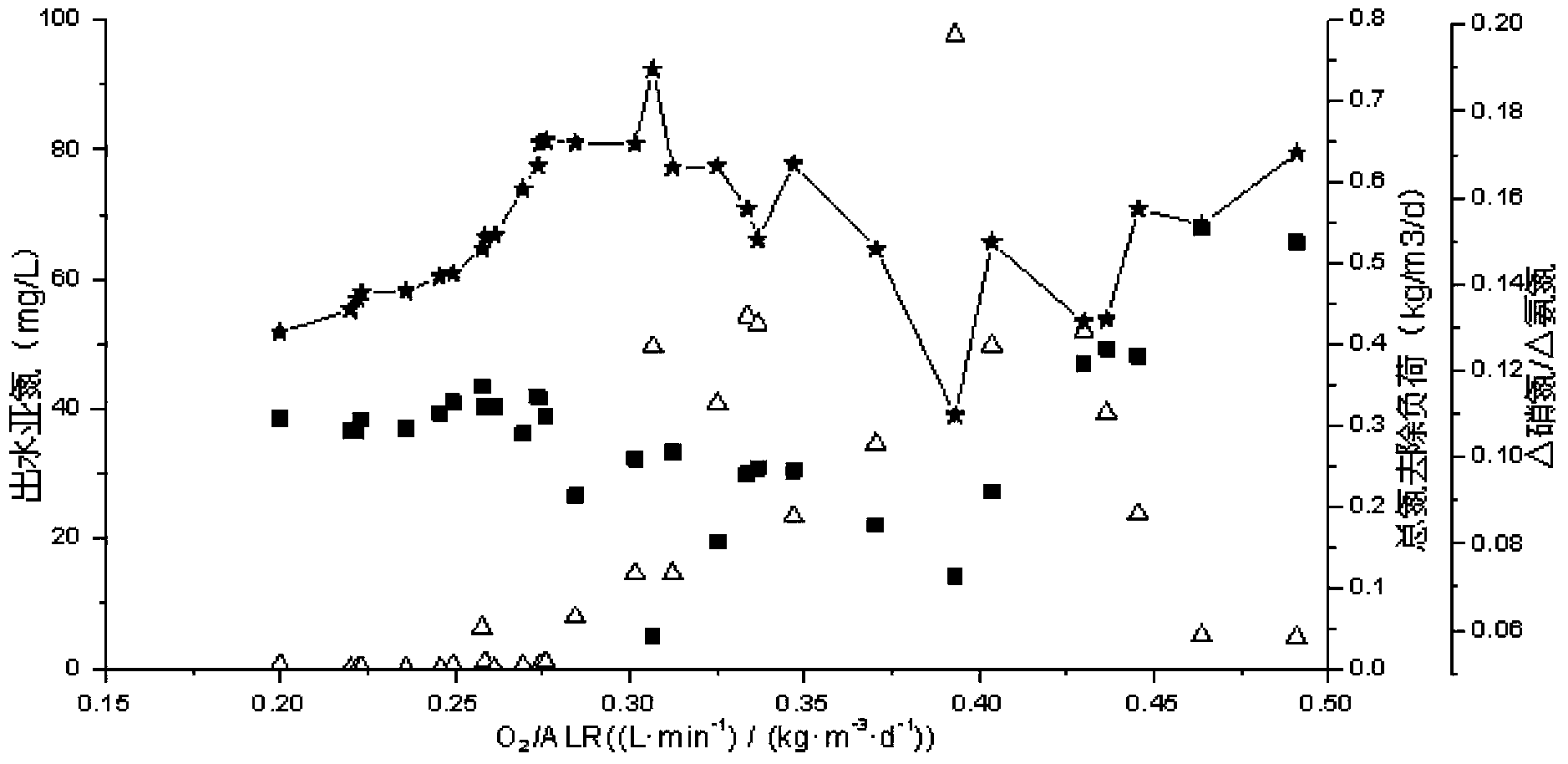

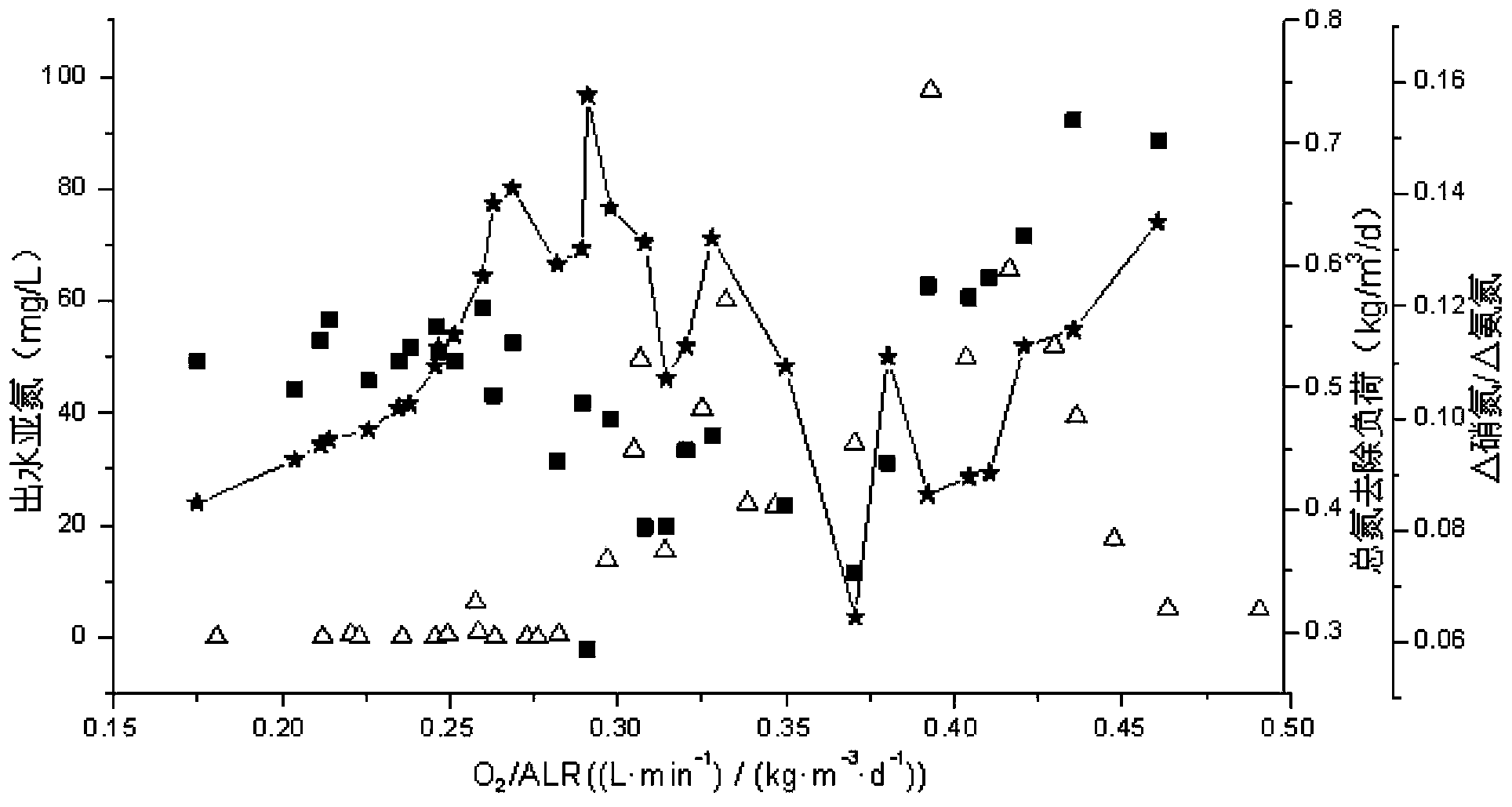

[0020] Inoculate CANON sludge in the autotrophic denitrification MBR reactor, the concentration of CANON sludge after inoculation is 3.0-4.0g / L, the temperature is 20-28°C, pH is 7.0-8.0, and the concentration of ammonia nitrogen is 40-400mg / L The sewage to be treated is passed into the autotrophic denitrification MBR reactor, and the ratio of the aeration rate to the influent ammonia nitrogen load (O 2 / ALR) is 0.25~0.30(L / min) / (kg / m 3 / d), realize the efficient and stable operation of the CANON process.

[0021] The autotrophic denitrification MBR reactor of this embodiment has no accumulation of nitrous during operation, the removal rate of ammonia nitrogen is over 90%, the removal rate of total nitrogen is over 80%, and △nitrate nitrogen / △ammonia nitrogen is 0.11~0.13, and it maintains ...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of CANON sludge after inoculation is 3.5 g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the temperature of the sewage to be treated is 22-26°C. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com