Recycling method of electroplating wastewater containing copper nitrate

A technology for electroplating wastewater and resource recovery, applied in copper nitrate, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve problems such as deteriorating operating conditions, reverse dissolution of cathode copper, and difficult process, and achieve short process flow and efficient wastewater treatment The effect of simplicity and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The reaction steps are as follows: use 1000 mesh industrial grade calcium carbonate to prepare a suspension with a mass fraction of 60% in terms of calcium oxide, and use this suspension to pre-mix copper nitrate-containing electroplating wastewater (copper containing about 50g / L, pH=0.3 ) to 1.5, remove insoluble matter, and obtain a clear liquid; then add a small amount of distilled water to the reaction kettle, and turn on the stirring device, while raising the temperature to 35°C, and then mix the pH-adjusted clear liquid with carbonic acid Calcium suspension (sufficient amount) is added to the reaction kettle at the same time, and the pH value is controlled at 6.0. After the addition is completed, the pH is maintained and the stirring is continued for 20 minutes. Finished product; the filtered filtrate of the product is concentrated, evaporated and crystallized to obtain calcium nitrate product.

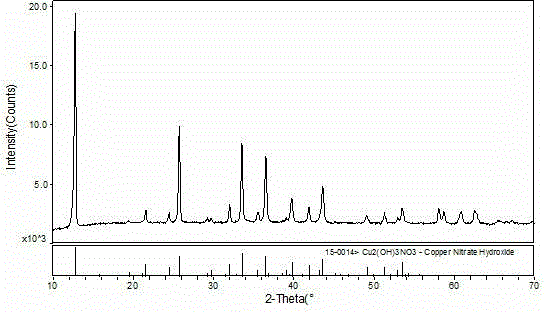

[0029] Detect the crystal composition and the structure of...

Embodiment 2

[0031] The reaction steps are as follows: use 700 mesh industrial grade calcium carbonate to prepare a suspension with a mass fraction of 20% in terms of calcium oxide, and use this suspension to pre-mix copper nitrate-containing electroplating wastewater (copper containing about 80g / L, pH=0.3 ) to 1.0, remove the insoluble matter, and obtain the clear liquid; then add a small amount of distilled water to the reaction kettle, and turn on the stirring device, while raising the temperature to 50°C, and then add the adjusted pH clear liquid (400ml ) and calcium carbonate suspension (sufficient amount) were added to the reaction kettle at the same time, and the pH was controlled at 4.5. After the addition was completed, the pH was maintained and continued to stir for 40 minutes. The product was filtered, washed, dried at 105°C, and crushed through a 60-mesh sieve. Finally, the finished product is obtained; the filtered filtrate of the product is concentrated, evaporated a...

Embodiment 3

[0034] The reaction steps are as follows: use reagent grade quicklime to prepare a suspension with a mass fraction calculated as calcium oxide of 40%, and pre-adjust the pH value of copper nitrate-containing electroplating wastewater (copper content is about 130g / L, pH=0.3) to 2.0 , remove the insoluble matter, and obtain the clear liquid; then add a small amount of distilled water to the reaction kettle, turn on the stirring device, and raise the temperature to 70°C at the same time, and then mix the clear liquid and the calcium hydroxide suspension (enough At the same time, add it to the reaction kettle, control the pH at 4.0, keep the pH and continue to stir for 30 minutes after the addition is completed, filter, wash, and dry the product at 70°C, crush it through a 60-mesh sieve, and finally get the finished product; the filtrate after the product is filtered Calcium nitrate products are obtained after concentration, evaporation and crystallization.

[0035] Dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com