Organic/inorganic composite colloidal dispersion gel and preparation method thereof

A colloidal dispersion and composite colloidal technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of short gel formation time, difficult to control, difficult to control, short crosslinking time, etc., and achieve gel formation. Time controllable, small environmental impact, and the effect of improving system viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

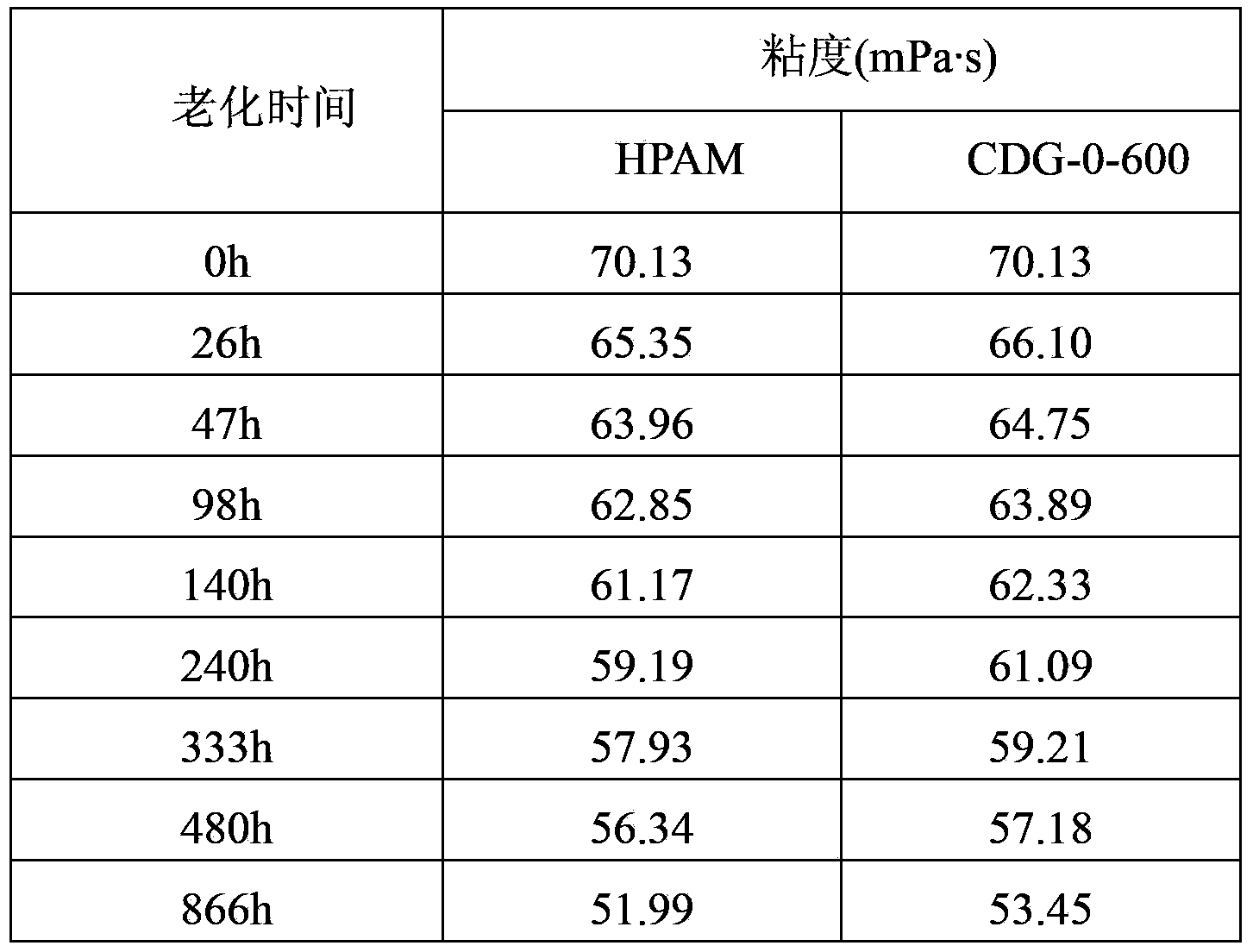

[0040] Embodiment 1, preparation CDG-25-0 and CDG-25-600

[0041] Configure a mineralized aqueous solution with a salinity of 6664mg / L (which contains 6190mg / L NaCl, 81.67mg / L KCl, 263.12mg / L CaCl 2 , 151.72mg / L MgCl 2 , 9.03mg / L Na 2 SO 4 , 43.75mg / L NaHCO 3), add partly hydrolyzed polyacrylamide, stir to dissolve, make HPAM solution with a concentration of 1750mg / L, adjust the pH to 7.0, add aluminum citrate to the solution and stir to dissolve so that the aluminum concentration reaches 25mg / L (take this sample and record it as CDG-25-0); continue to add tetramethylol glycoluril to it, stir and dissolve to make the content reach 600g / L, and obtain the product of the present invention, and the sample number is marked as degradation sample CDG-25-600. Constant temperature aging at 60°C.

[0042] Samples were taken for viscosity measurement when the aging time was 0h, 26h, 47h, 98h, 140h, 240h, 333h, 480h and 866h.

[0043] The intermediate sample CDG-25-0 was also aged at...

Embodiment 3

[0048] Example 3. Preparation of CDG-120-0 and CDG-120-600 (aging at 60°C)

[0049] Configure a mineralized aqueous solution with a salinity of 6664mg / L (which contains 6190mg / L NaCl, 81.67mg / L KCl, 263.12mg / L CaCl 2 , 151.72mg / L MgCl 2 , 9.03mg / L Na 2 SO 4 , 43.75mg / L NaHCO 3 ), add partly hydrolyzed polyacrylamide, stir to dissolve, make HPAM solution with a concentration of 1750mg / L, adjust the pH to 7.0, add aluminum citrate to the solution and stir to dissolve so that the aluminum concentration reaches 120mg / L (this sample is recorded as CDG -120-0), add tetramethylol glycoluril to sample CDG-120-0, stir and dissolve to make the content reach 600g / L, and obtain the product of the present invention, and the sample number is recorded as degradation sample CDG-120-600 constant temperature 60 ℃ aging.

[0050] Samples were taken for viscosity measurement when the aging time was 0h, 26h, 47h, 98h, 140h, 240h, 333h, 480h and 866h.

[0051] Viscosity measurements were perf...

Embodiment 4

[0055] Embodiment 4, preparation CDG-120-1000

[0056] The steps in Example 3 are basically the same, except that tetramethylol glycoluril is added to make the content reach 1000g / L to obtain the product of the present invention, the sample number is marked as degradation sample CDG-120-1000, and the temperature is 60°C Ageing.

[0057] Samples were taken for viscosity measurement when the aging time was 0h, 26h, 47h, 98h, 140h, 240h, 333h, 480h and 866h.

[0058] Viscosity measurements were performed at 25°C with the rotor shear rate fixed at 7.26s -1 , Various viscosities are listed in Table 4.

[0059] Table 4 Viscosity change of aging sample CDG-120-1000 at 460°C

[0060] aging time

[0061] 333h

[0062] It can be seen from Table 4 that, compared with the sample CDG-120-600, when the amount of tetramethylol glycoluril added increases from 600 mg / L to 1000 mg / L, the viscosity of the sample CDG-120-1000 decreases slightly. This is because as the amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com