Process for forming piles on mine dumping field

A technology for dumping dumps and piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of difficulty in forming large-diameter holes, and achieve the effect of improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

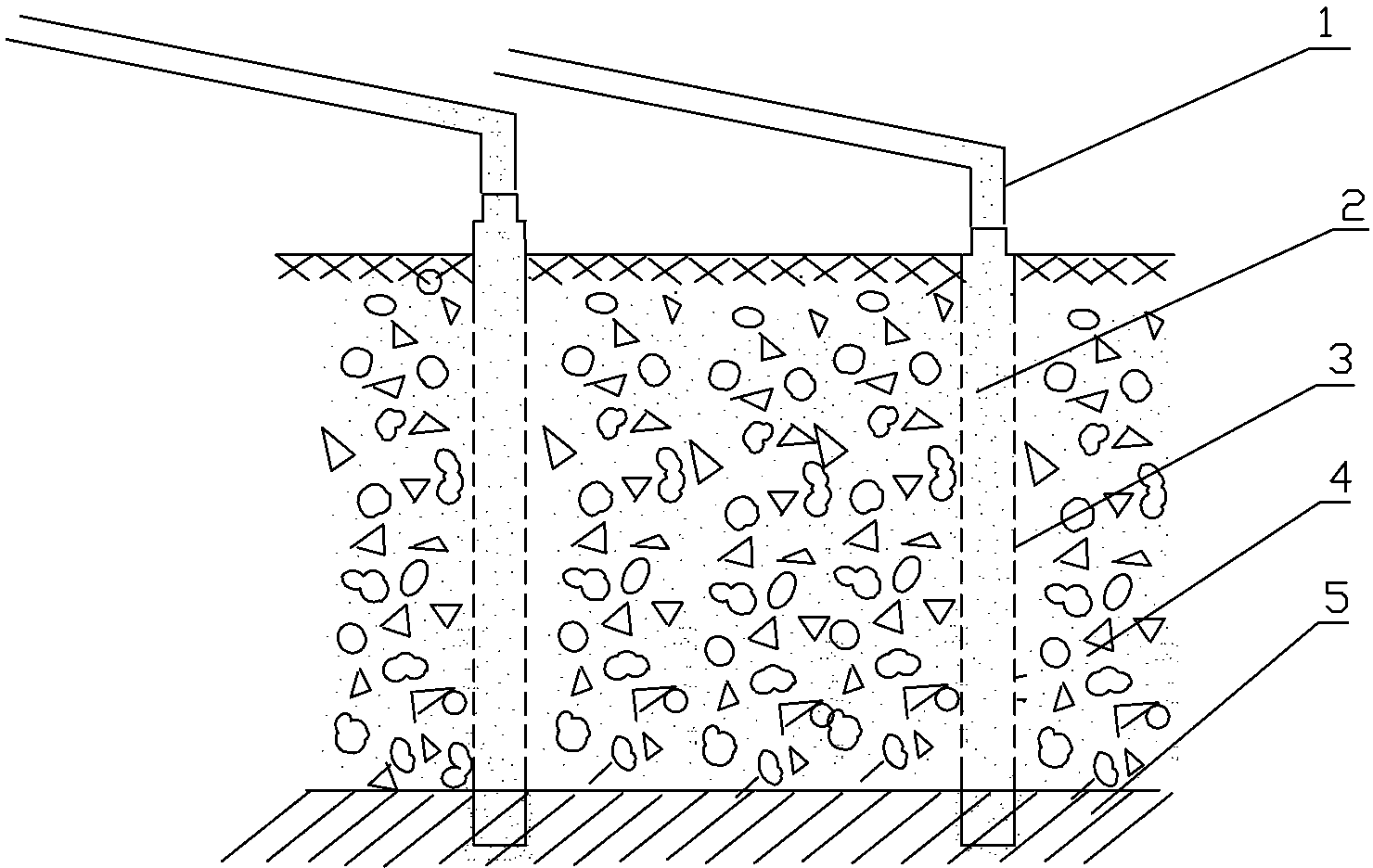

[0030] A unit builds a belt corridor, and the support foundation of the belt corridor is located on the dump site. The stratum distribution of the dump site is as follows: the newly discharged gravel soil is 8-11 meters, the maximum particle size is 350 mm, and the structure is loose; the slope accumulation soil 1-2 meters, clay containing gravel, the characteristic value of bearing capacity is 180kpa; strongly weathered mixed rock is 2-3 meters, the characteristic value of bearing capacity is 600kpa; the layer of moderately weathered mixed rock is not penetrated, the characteristic value of bearing capacity is 1500kpa; the original ground slope 35 degrees.

[0031] The design adopts eccentric down-the-hole hammer and pipe drill. The casing is a straight seam welded pipe processed by 5 mm thick Q235b steel plate. 2 meters of mixed rock is the standard end hole), the diameter of the drill hole is 159 mm, the pile caps of three equilateral piles, the pile distance is 0.8 meters,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com